Gas pipeline with reducing speed increase and anti-backflow blocking for gas water heater

A technology for gas water heaters and gas pipelines, which is applied to fluid heaters, lighting and heating equipment, and combustion methods. It can solve problems such as inability to heat immediately, inability to transport gas, and blockage of gas pipelines, and achieve the effect of accelerating the emission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

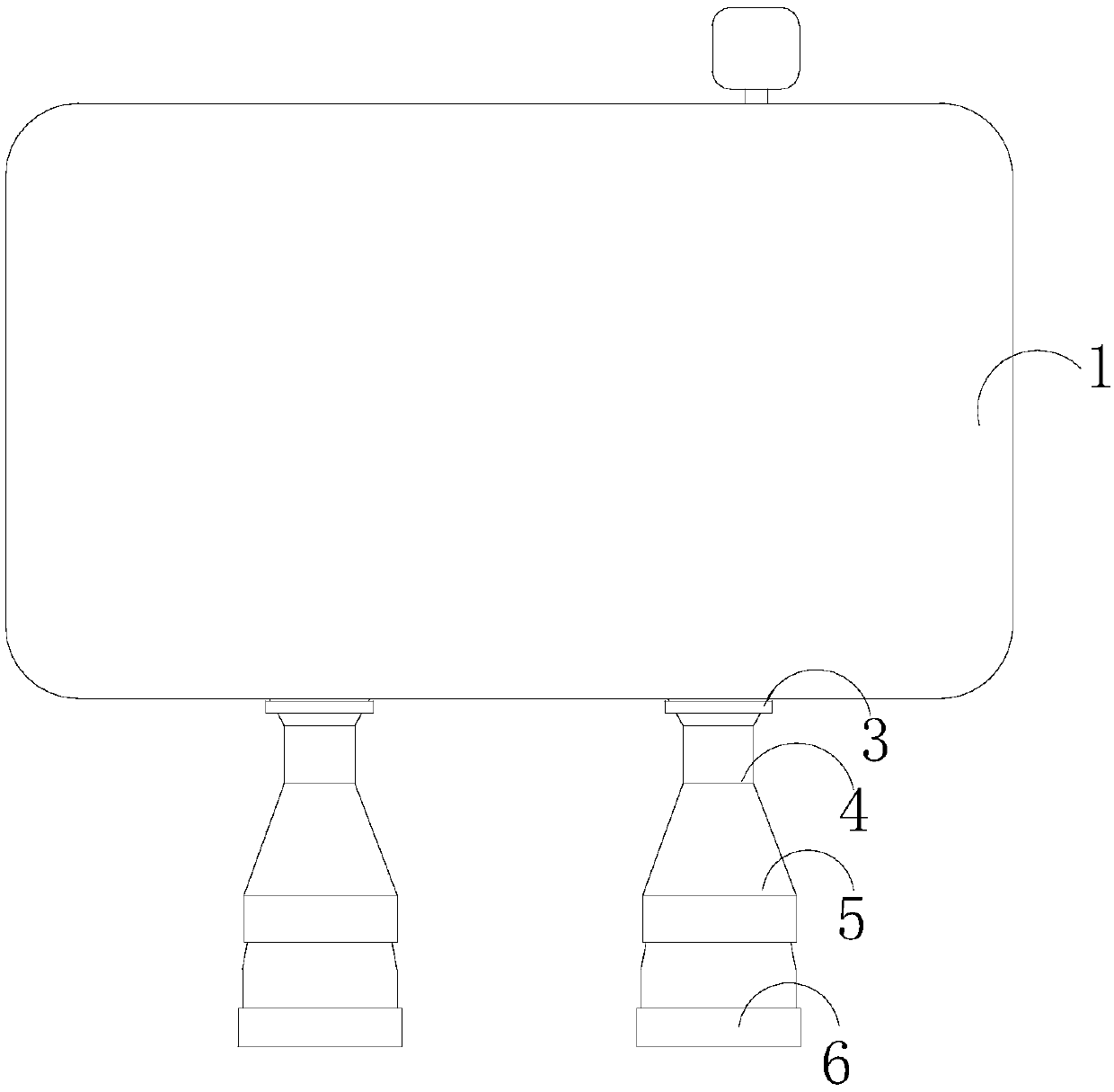

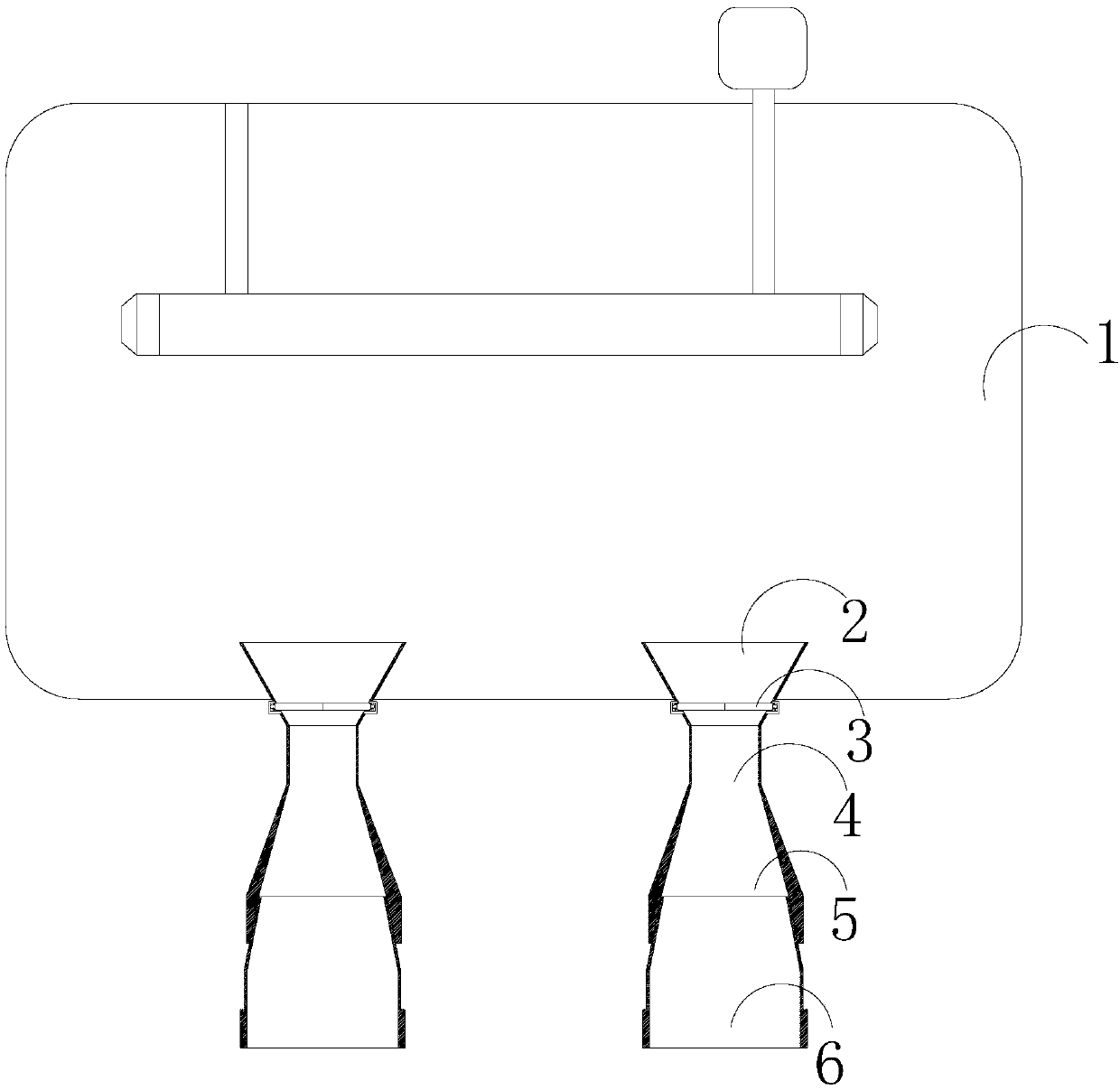

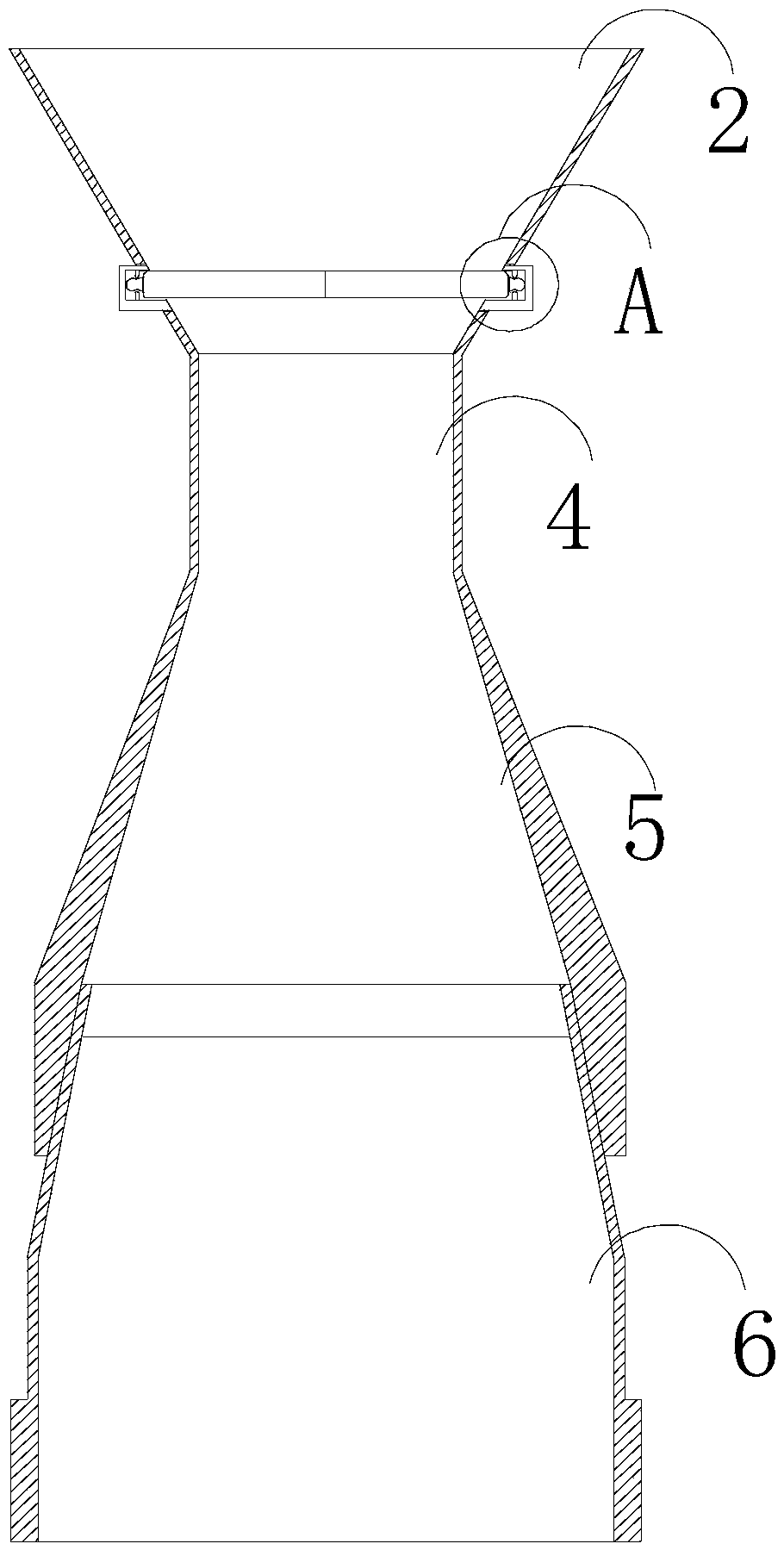

[0021] see Figure 1-Figure 6 , the present invention provides gas pipes for gas water heaters with variable diameters, increased speed and anti-reflux clogging. 4. Both horizontal ends are respectively connected to the diffuser tube 2 and the shrink tube 5. The diffuser tube 2 and the shrink tube 5 are both hollow structures. The height of the shrink tube 5 is smaller than that of the diffuser tube 2. The end of the diffuser tube 2 is located in the combustion chamber 1, a nozzle 6 is installed in the middle of the end of the shrink tube 5, and a stop structure 3 is installed on the diffuser tube 2 near the straight tube 4. The diffuser tube 2 and the shrink tube 5 are not mechanically connected to the straight tube 4. The diameter of one end is larger than that of the other end, and the three tubes of the diffuser tube 2, the straight tube 4 and the shrink tube 5 are on the same straight line and communicate with each other.

[0022] The flow-stopping structure 3 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com