Split-type guiding sliding shoe

A kind of guide sliding shoe, split technology, applied in the direction of slitting machinery, engine lubrication, propulsion, etc., can solve the problems of shortening the life of the sliding shoe, equipment wear and tear, etc., to achieve convenient replacement operation, reduce impact, reduce wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

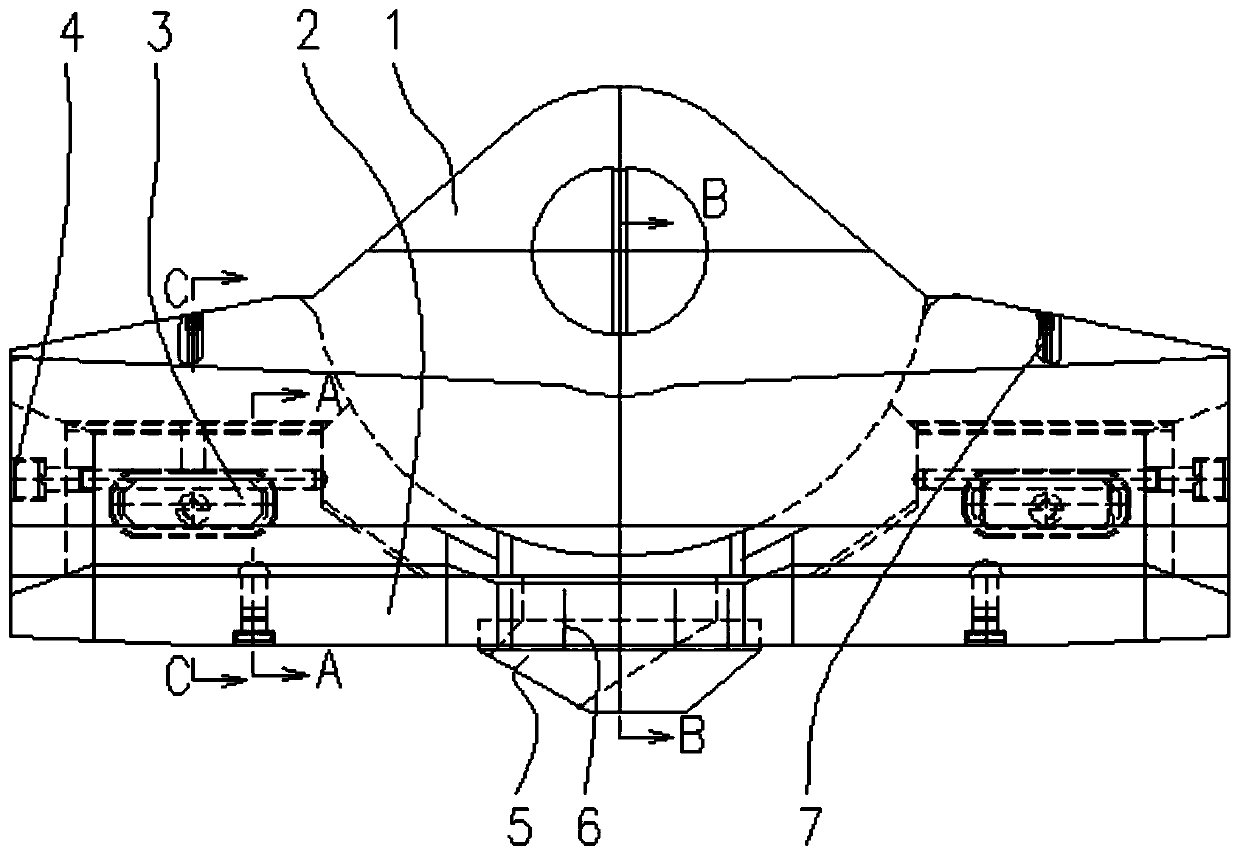

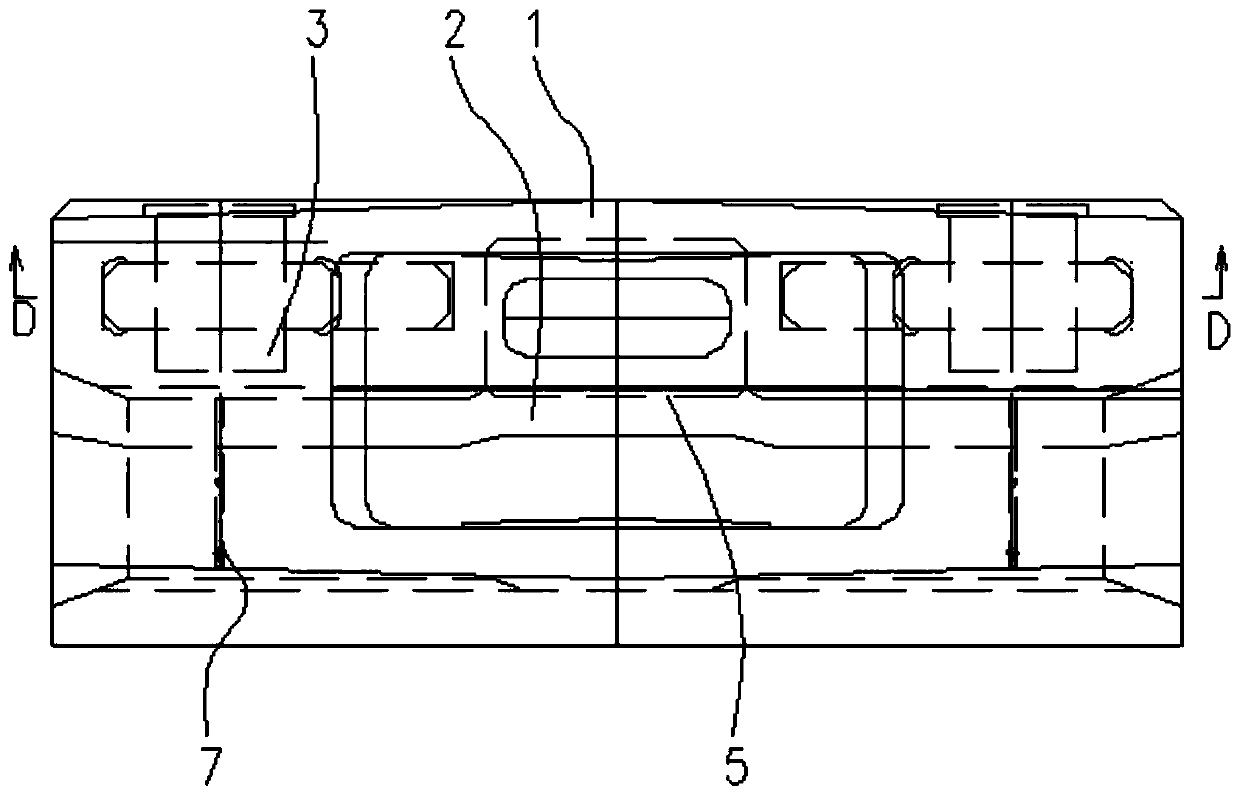

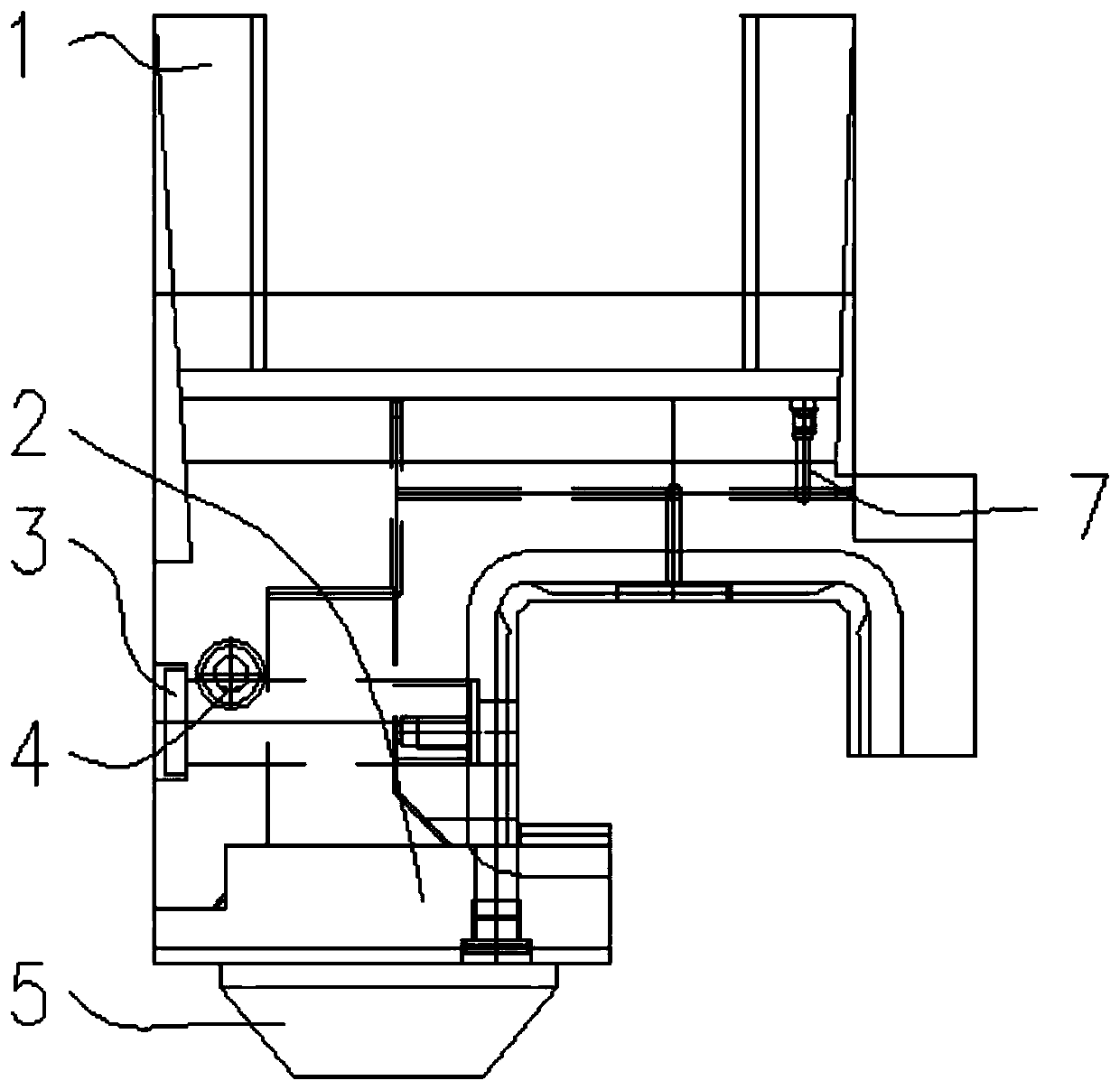

[0037] The invention discloses a split guide shoe, such as Figure 1-11As shown, it includes a main sliding shoe 1, a bottom hook 2, a positioning block 3, a pin 4 and a leakage block 5, and the main sliding shoe and the bottom hook are left-right symmetrical structures. The front part of the main shoe base of the main shoe is provided with a guide groove extending left and right, the bottom of the guide groove is open, and the left and right are penetrated. The surface of the guide groove is the front wear layer 1031, the top resistance Grinding layer 1032 and rear wear layer 1033. The bottom hook includes a bottom hook base and a bottom hook protrusion 201 on the left and right sides of the bottom hook base. The existence of the bottom hook protrusion makes the longitudinal cross-sections of the left and right parts of the bottom hook roughly in an inverted T shape. . The left part and the right part of the bottom hook are respectively plugged up and down with the rear par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com