Sterilization bioreactor

A bioreactor, barrel technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instruments, etc., can solve problems such as unfavorable, easily damaged cells, and large damage to plant cells. , to achieve the effect of facilitating the reaction and use, extending the flow distance, and ensuring the sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

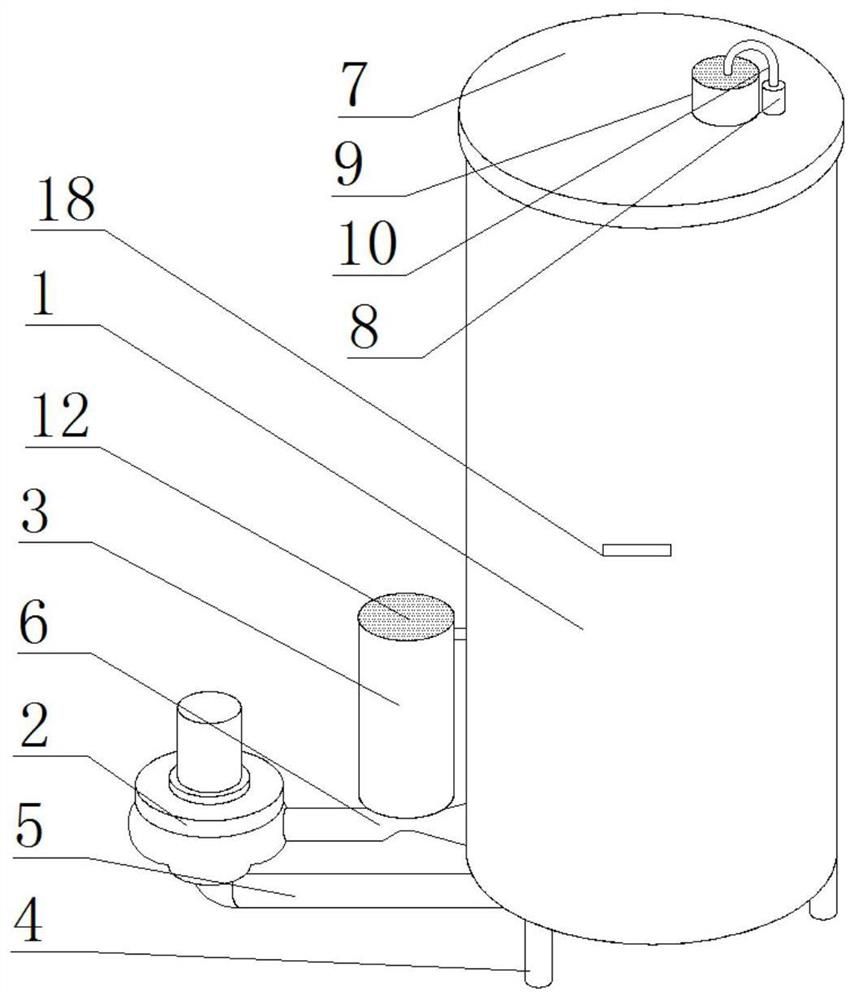

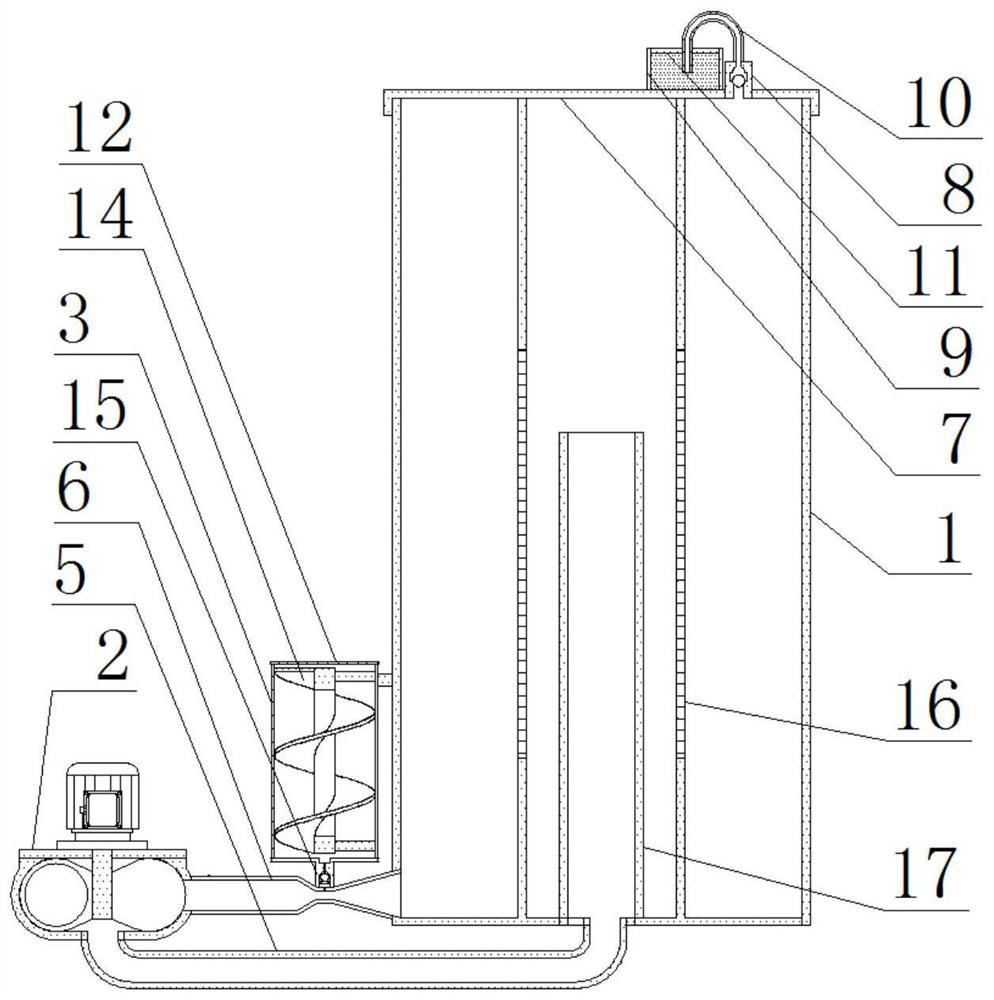

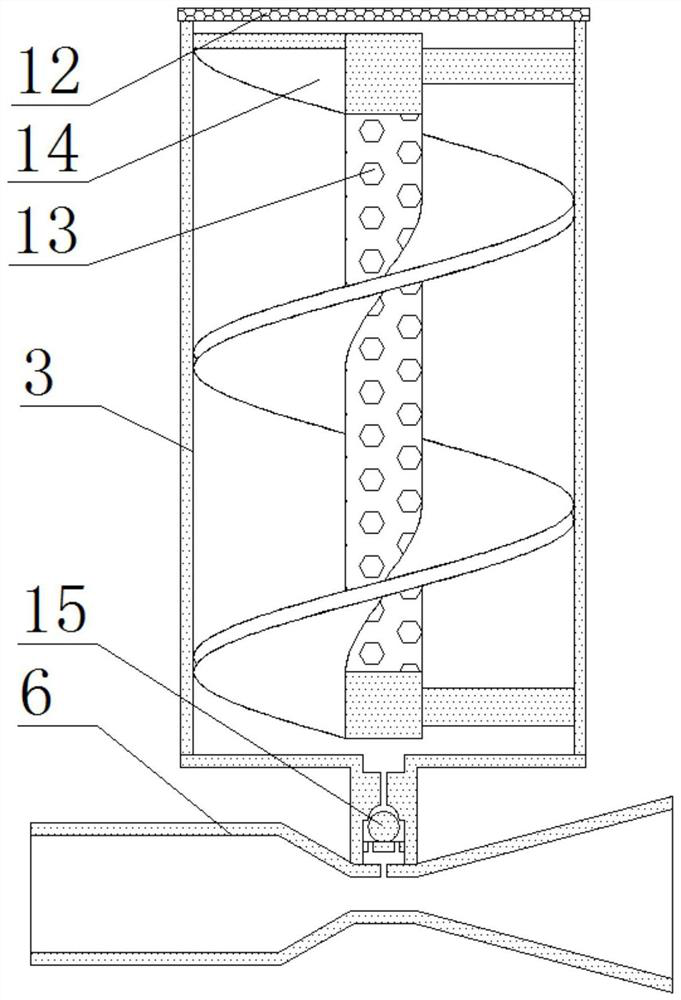

[0026] see figure 1 with figure 2 , the present invention provides a technical solution: a sterilizing bioreactor, including a barrel body 1, a water pump 2 and a sleeve 3, the sleeve 3 is welded on one side of the barrel body 1, and the water pump 2 is arranged on the barrel body One side of the body 1, the bottom of the bucket body 1 is welded with a bracket 4, the bottom of the water pump 2 is welded with a connecting pipe 5, one side of the water pump 2 is welded with a Venturi tube 6, and the bottom of the bucket body 1 is welded with a connecting pipe 5. A bung 7 is installed on the top, a one-way valve-8 is installed on the top of the bung 7, a ferrule 9 is welded on the top of the bung 7, and a trachea 10 is bonded on the top of the one-way valve-8, The top of the ferrule 9 is equipped with a filter screen 11 through bolts, the top of the sleeve 3 is equipped with a filter plate 12 through bolts, and the inner wall of the sleeve 3 is equipped with a disinfection lamp...

Embodiment 2

[0028] See figure 1 with Figure 4 The difference from Embodiment 1 is that the switch 18 is connected with the water pump 2 and the disinfection lamp 13 through wires, the bottom of the barrel body 1 is welded with a port, and one end of the connecting pipe 5 is welded at the bottom of the port , the water pump 2 communicates with the bottom of the barrel body 1 through the connecting pipe 5, one side of the water pump 2 communicates with the side of the barrel body 1 through the venturi tube 6, and one end of the venturi tube 6 is attached to On the inner wall of the barrel body 1, the water pump 2 can be turned on through the switch 18, and the water pump 2 can extract the liquid in the sleeve 1 through the connecting pipe 5, and spray it to the inner wall of the barrel body 1 through the Venturi tube 6, and the ejected liquid is along the The inner wall of the barrel body 1 flows, and then pushes the liquid in the barrel body 1 to rotate and flow in the barrel body 1, whi...

Embodiment 3

[0030] See image 3 The difference from Example 2 is that the top of the Venturi tube 6 is provided with an air hole, the check valve 2 15 is welded on the top of the air hole, the sleeve 3 communicates with the Venturi tube 6, and the liquid When the venturi tube 6 flows into the barrel body 1 at high speed, a negative pressure is generated in the middle of the venturi tube 6, and then a suction force is generated on the check valve 2 15 through the air hole, so that the air in the sleeve 3 enters the venturi tube 6, after the air enters the Venturi tube 6, it is dispersed by the high-speed flow of liquid, and then dispersed microbubbles are formed in the liquid. Using the characteristics that the microbubbles can stay in the liquid for a long time, the liquid is greatly improved. The amount of dissolved oxygen, thereby ensuring sufficient oxygen supply in the barrel body 1, and ensuring the oxygen consumption of the biological reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com