A robot-based inspection line for rotor blades

A robotic technology and rotor blade technology, applied in the field of rotor blade detection lines, can solve the problems of time-consuming and laborious positioning or unlocking process, affecting detection accuracy, rotor blade damage, etc., to avoid detection accuracy, avoid damage, and tightly adsorb and fix Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

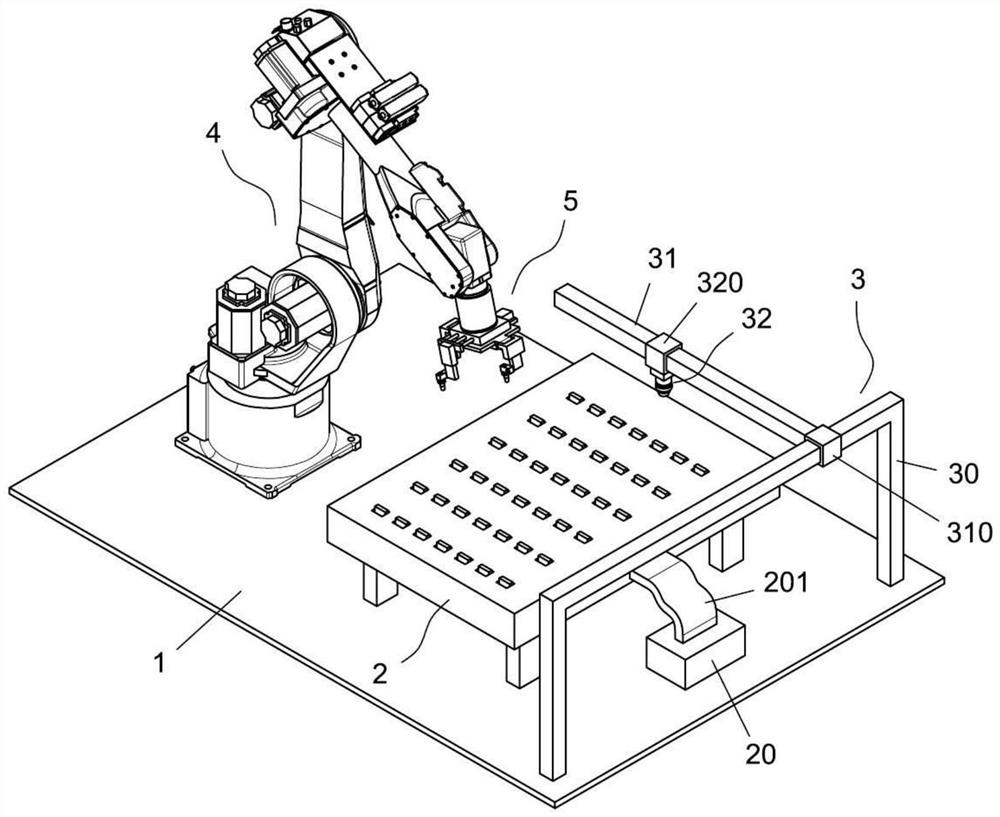

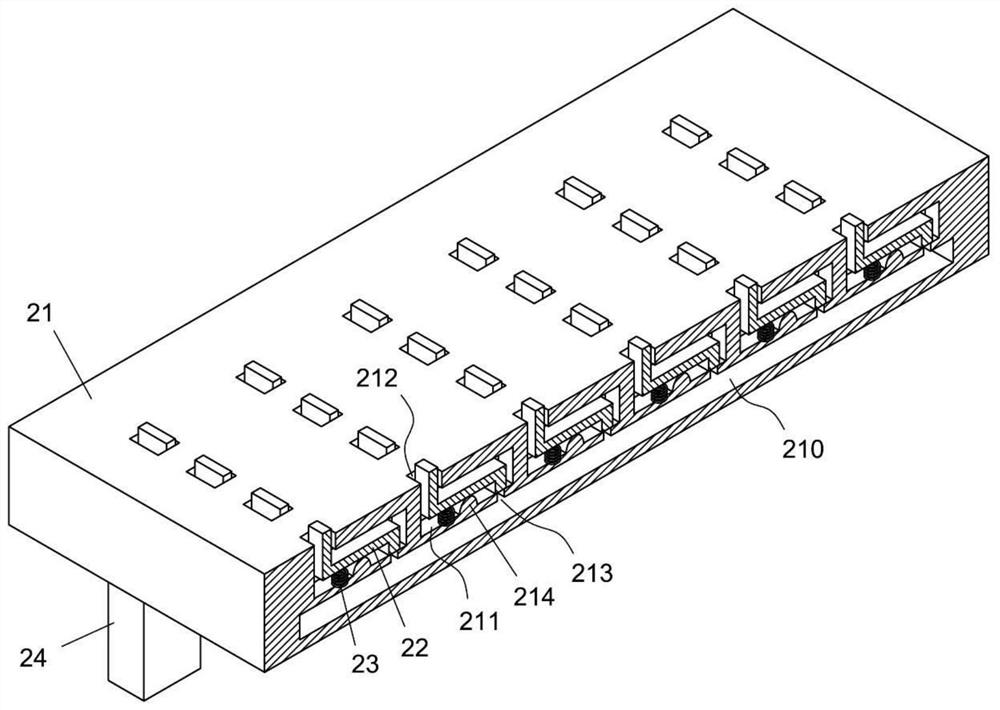

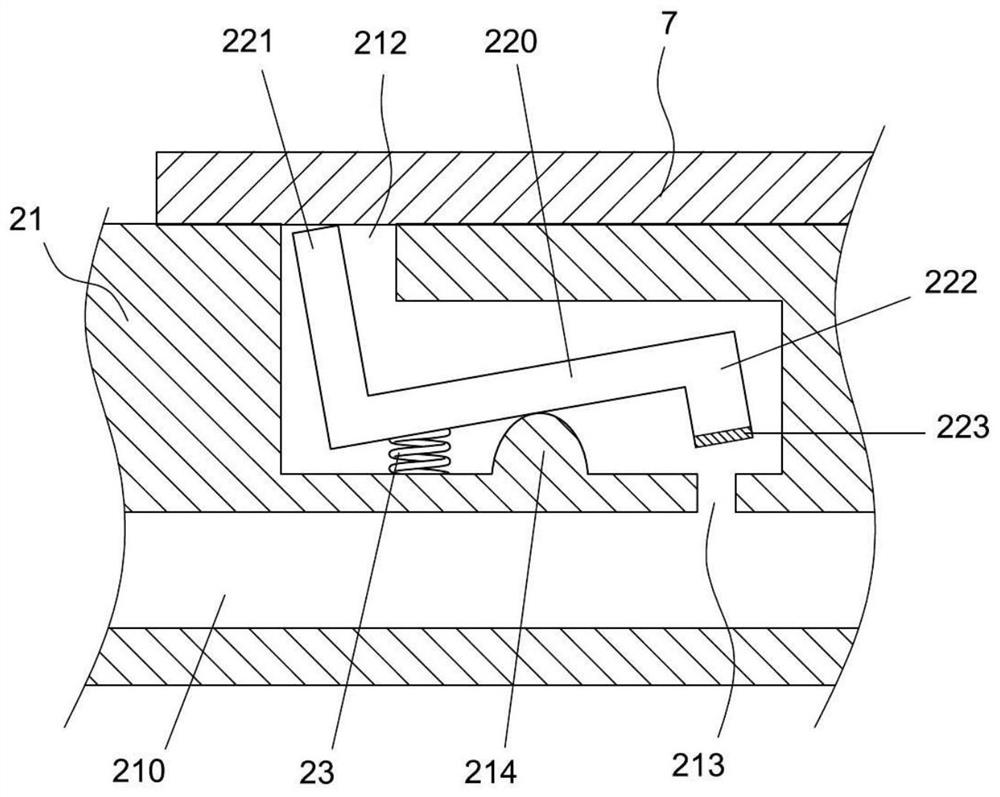

[0023] like Figure 1-8 As shown, a robot-based rotor blade detection line includes a multi-degree-of-freedom hoisting robot 4 fixed on the base 1, a positioning mechanism 2 for fixing the rotor blade 7, and a detection unit 3 for detecting the rotor blade 7 And a control system (not shown in the figure), wherein, the positioning mechanism 2 is located between the multi-degree-of-freedom lifting robot 4 and the detection unit 3, and the control system is connected with the multi-degree-of-freedom lifting robot 4, the positioning mechanism 2 and the detection unit 3. Electrical connection; the end of the multi-degree-of-freedom hoisting robot 4 is connected with a material transfer manipulator 5 .

[0024] The positioning mechanism 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com