Optimization method of molecular beam epitaxy growth AlInAsSb superlattice material

A molecular beam epitaxy and optimization method technology, applied in the field of semiconductor materials, can solve the problems of poor uniformity of large areas of materials, complex device manufacturing processes, and device application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

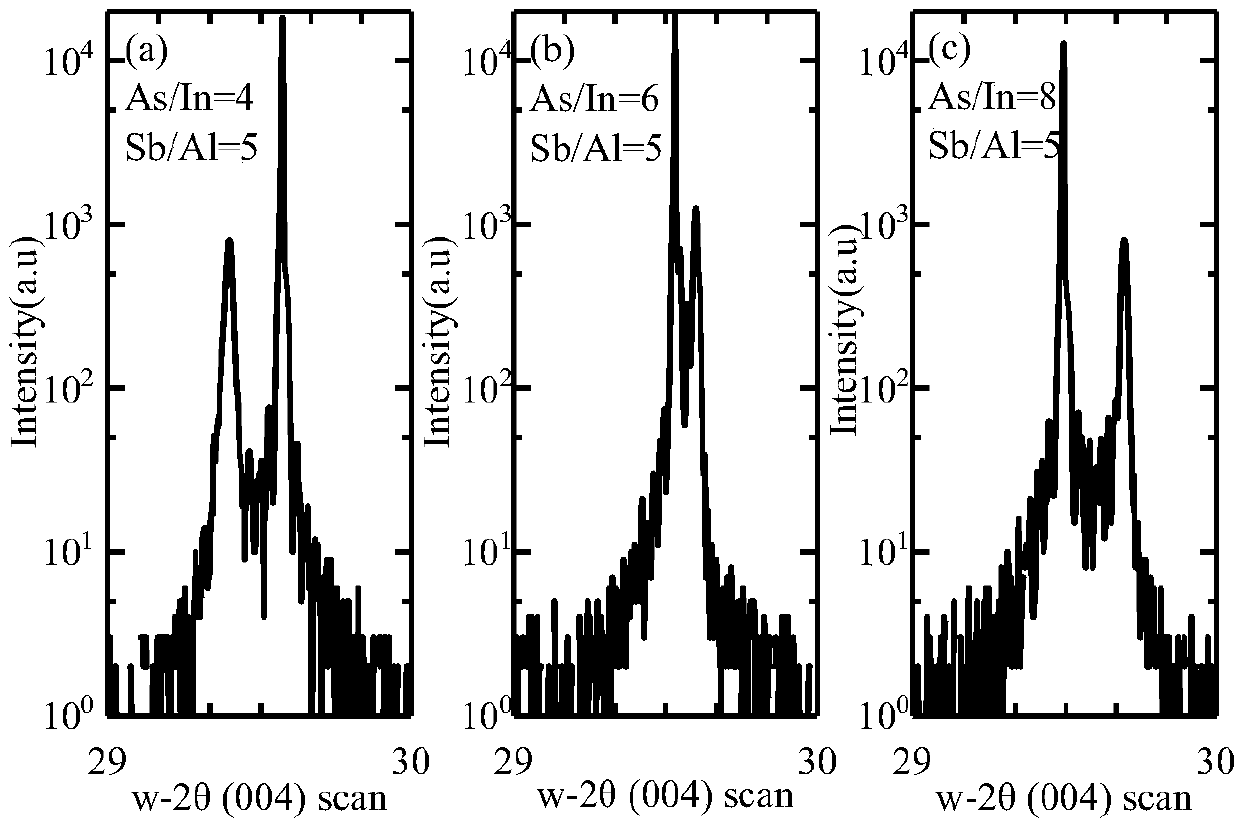

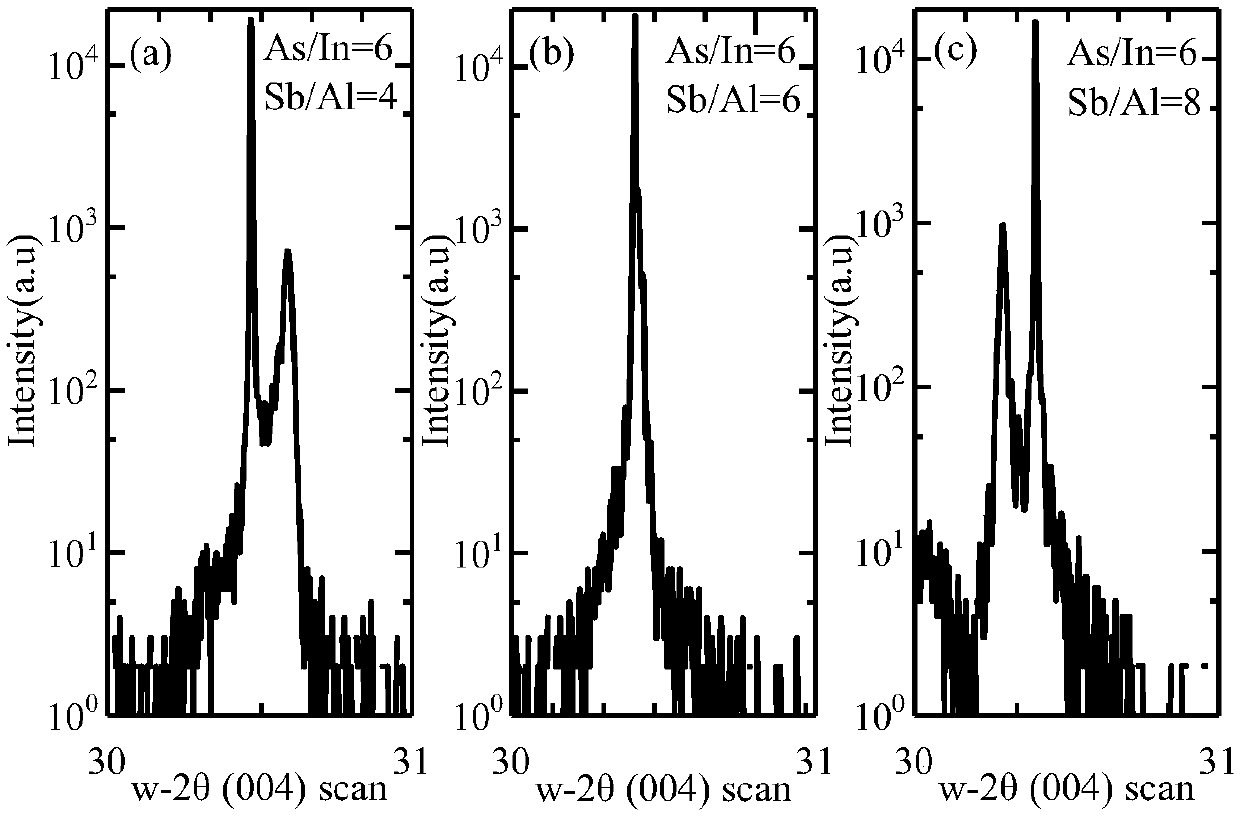

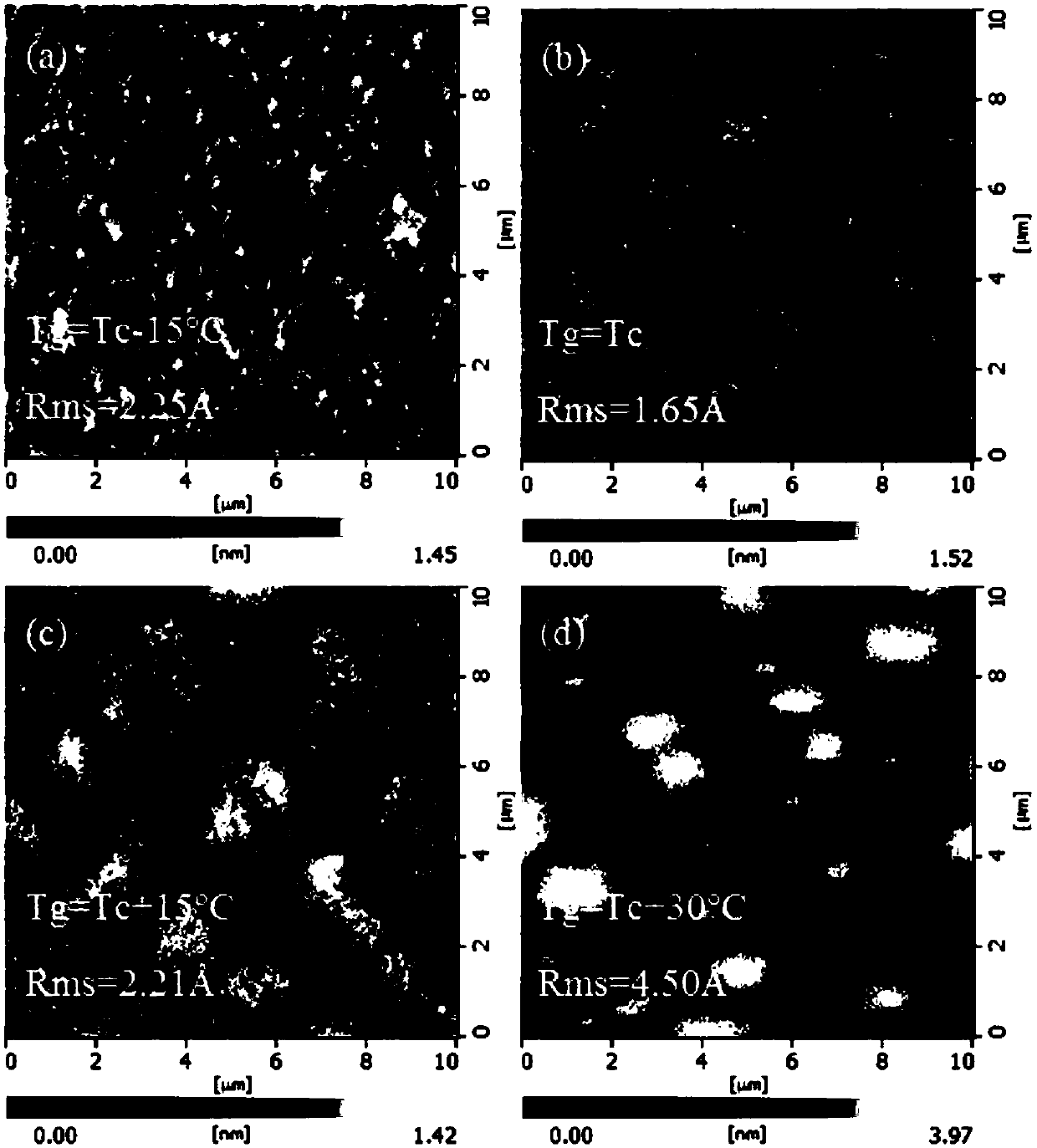

[0035] In this embodiment, an optimized growth method of a short-wavelength AlInAsSb superlattice material is provided. The structure used in the material optimization growth method is as follows from bottom to top: GaSb substrate, 200nm thick GaSb buffer layer, 30nm AlSb barrier layer, 40 periods of AlInAsSb superlattice, 30nm AlSb barrier layer and 20nm GaSb capping layer. Among them, the AlSb layer above and below the superlattice is used to limit the movement of carriers for better PL spectrum testing. The method adopts the alloy technology to prepare the AlInAsSb superlattice material, and the shutter sequence is as follows: AlSb, AlAs, AlSb, Sb, In, InAs, In, Sb (the interface sequence is an optimized sequence). The optimization method of the present invention comprises the following specific steps:

[0036] (1) Substrate pre-degassing: put a 2-inch double-sided polished GaSb substrate into the intro chamber, and wait until the vacuum degree is reduced to 1.6×10 -6 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com