Inspection system of remote operated vehicle on submarine cable and operation method of inspection system

An underwater robot and submarine cable technology, which is applied to underwater operation equipment, cable installation, underwater ships, etc., can solve problems such as limited operation range, robot damage, loss, etc. The effect of inspecting the quality and preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

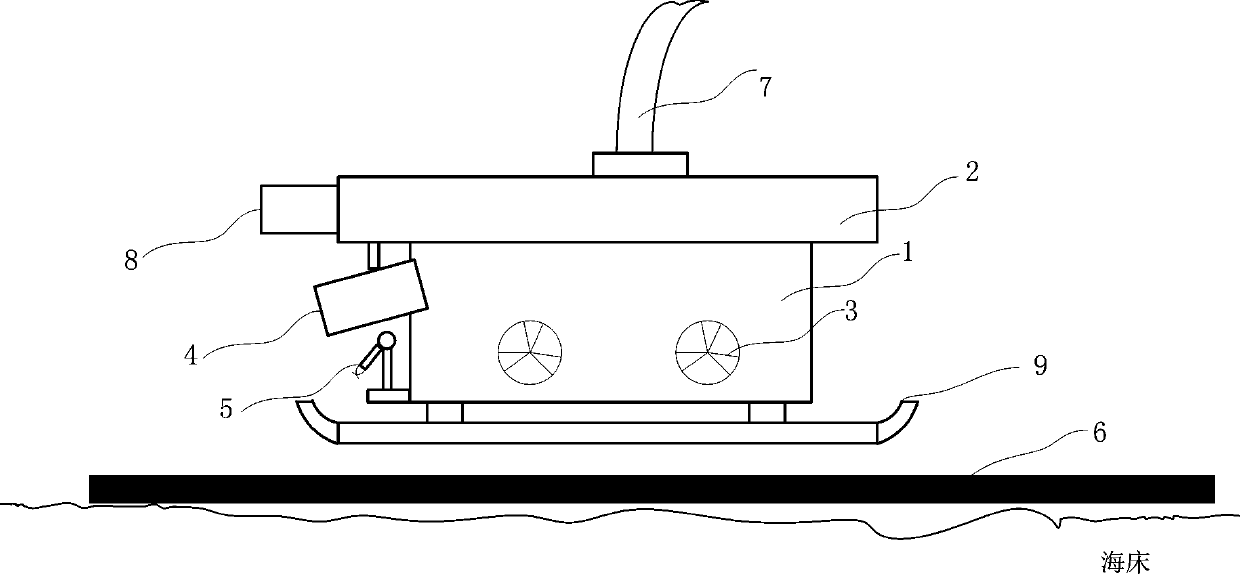

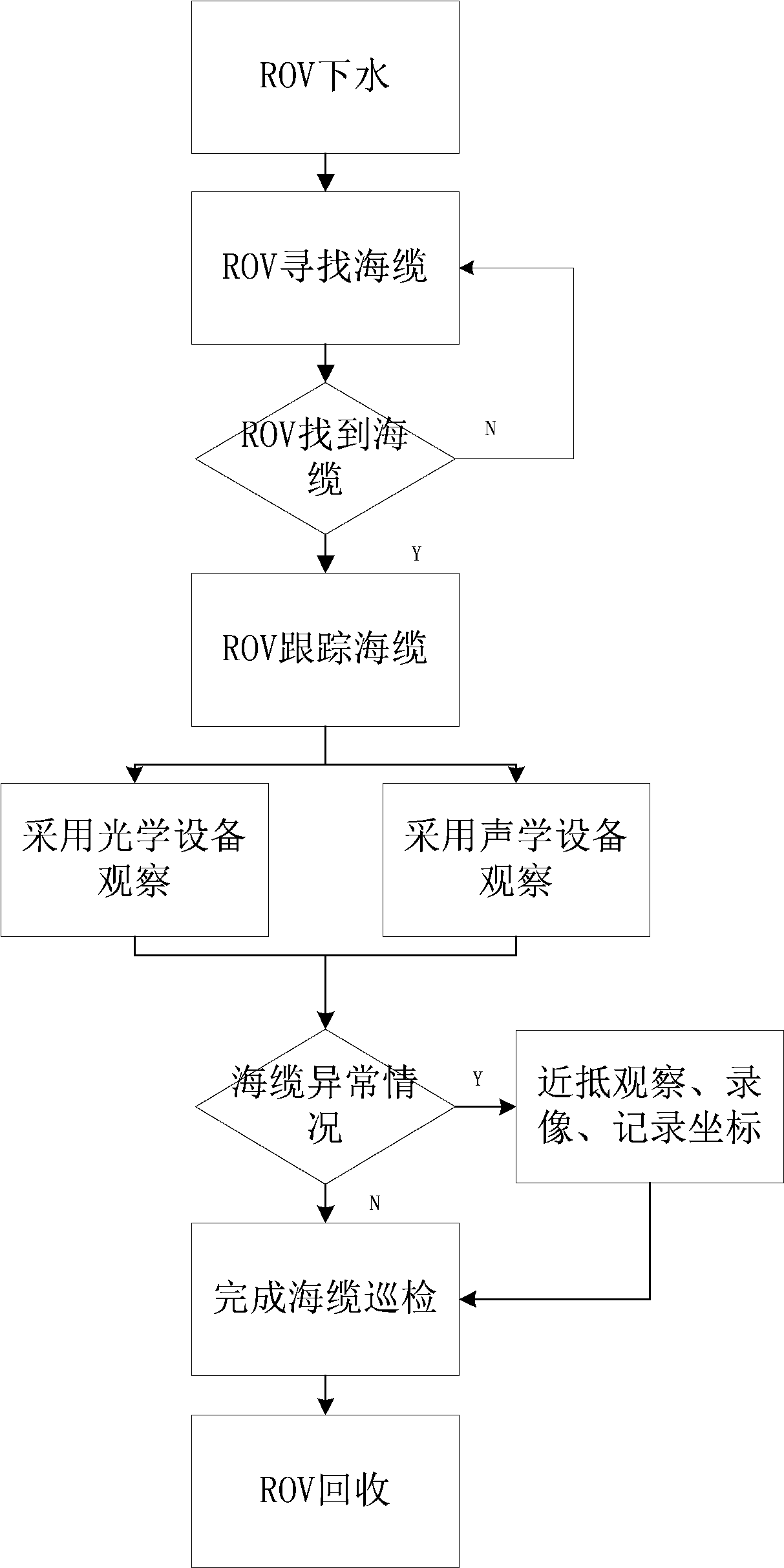

[0034] like figure 1As shown, the inspection system of the cable remote-controlled underwater robot to the submarine cable includes the underwater robot and the work boat connected with the underwater robot. The work boat is connected with the underwater robot through the umbilical cable 7 to control the underwater robot and provide electric energy. For an underwater robot; the underwater robot includes a ROV body 1, a floating body 2 arranged on the top of the ROV body 1, a propeller 3 arranged on the ROV body 1, an illumination and photographing device 4 arranged at the front of the ROV body 1, The mechanical arm 5 located at the front of the ROV body 1, the underwater positioning device used for positioning the underwater robot, and the feet 9 located below the ROV body 1; during work, according to the pre-submarine cable 6 routin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com