Seven-kneading and eight-drying preliminary processing system

A primary processing, drying and screening technology, applied in the fields of application, food processing, food science, etc., can solve the problems of weed cabbage breaking, inability to process weed cabbage, and inability to adapt to large-scale processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] In order to make the objectives and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with embodiments. It should be understood that the following text is only used to describe one or several specific embodiments of the present invention, and does not strictly limit the protection scope of the specific claim of the present invention.

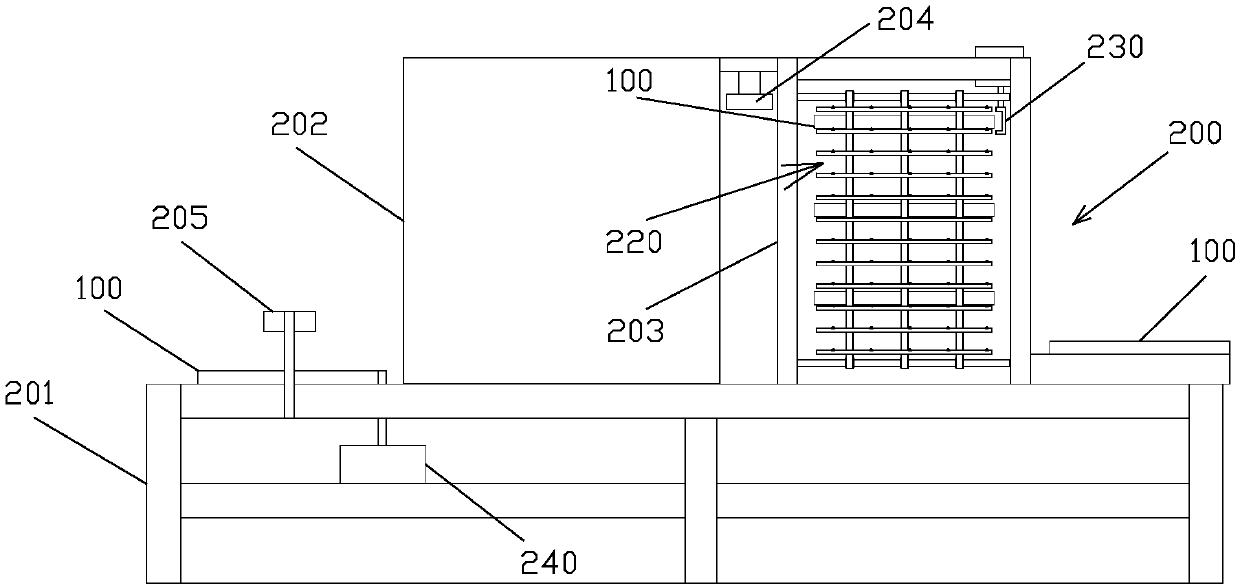

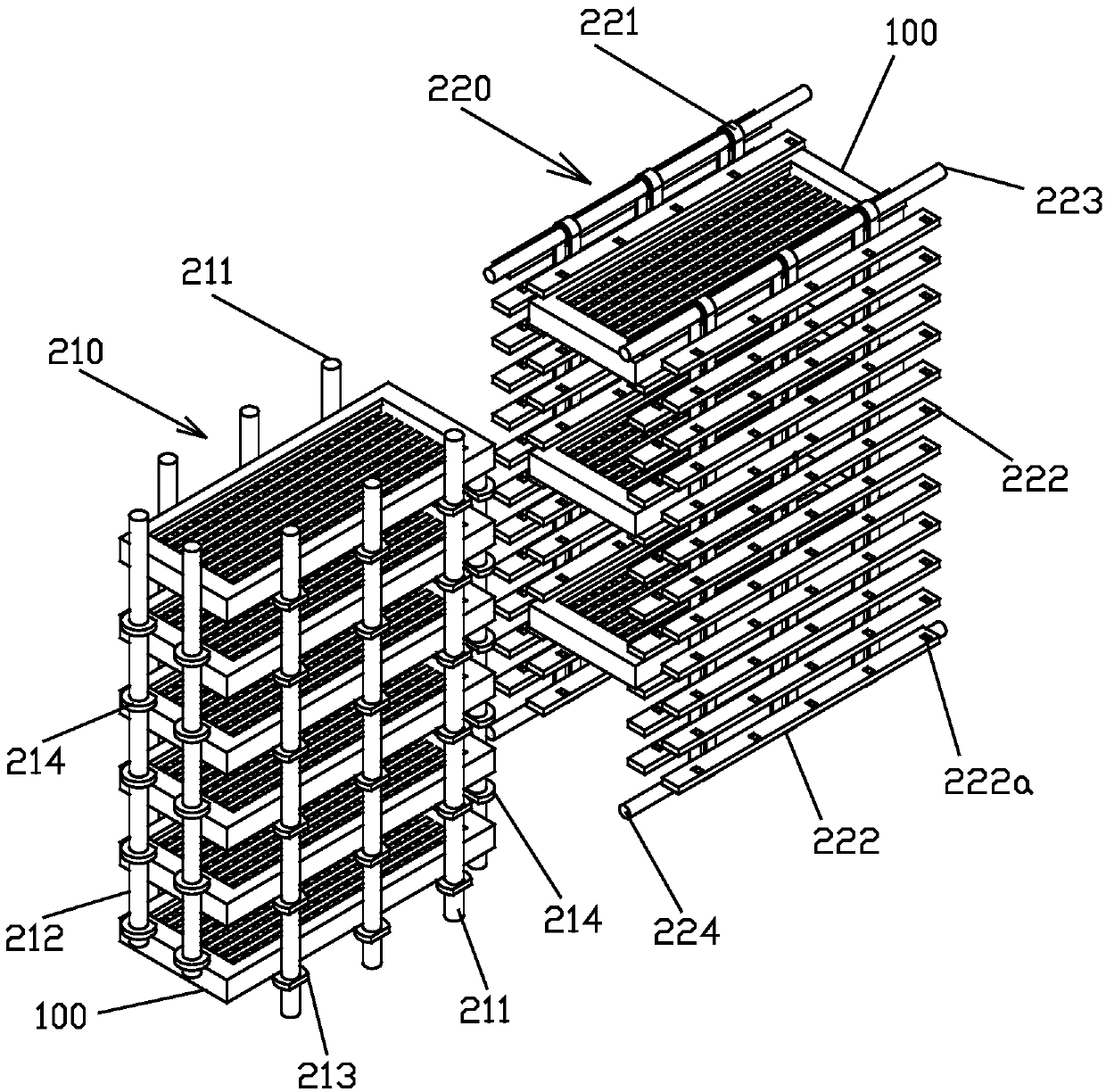

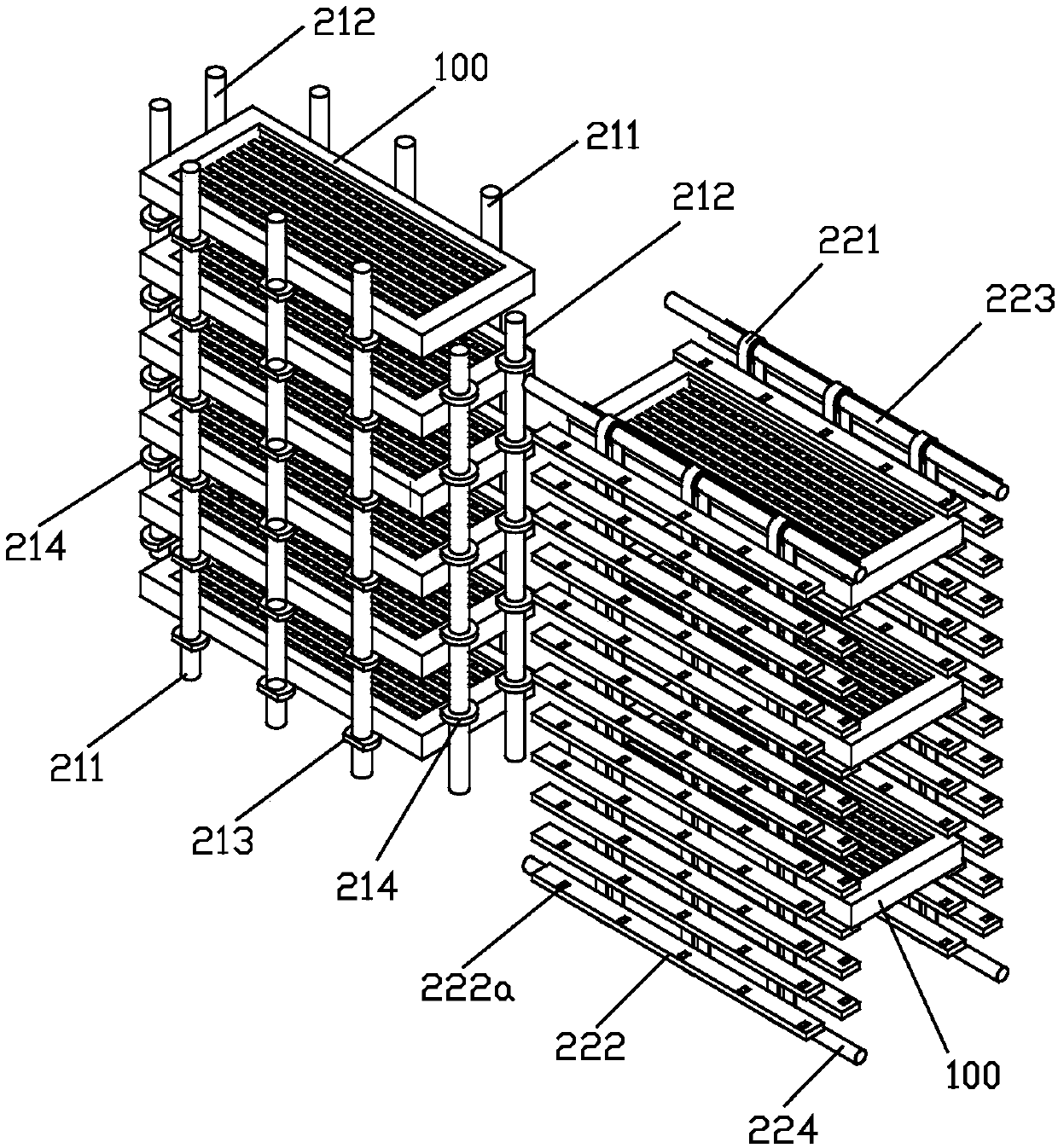

[0094] The present invention provides an Osmunda kneading and drying unit (system), which includes drying equipment for drying Osmunda oleracea and arranged between adjacent drying equipments for kneading Osmunda oleracea. Kneading table 300.

[0095] Through research, it is found that comprehensively considering the processing efficiency of Osmunda oleracea and the quality of the finished dried Osmunda oleracea, it is preferable to use the traditional manual "seven kneading process" for operation. The traditional "seven-kneading process" refers to processing the blanched Osm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com