Component assembling system for door and window panels

A technology for assembling systems and door and window panels, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of loose outer frame and uneven artificial gluing, achieve smooth transmission, ensure even gluing and installation. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

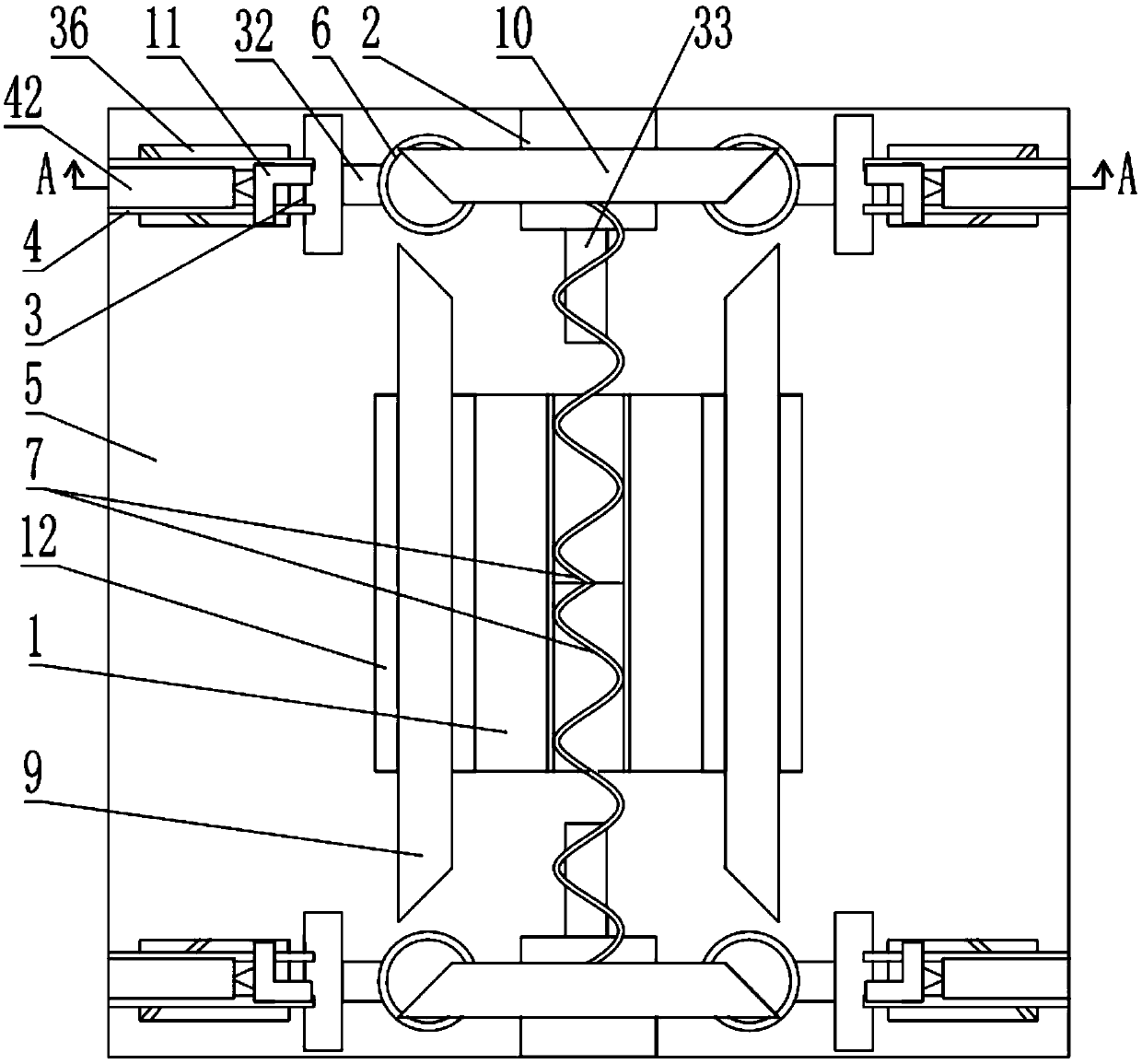

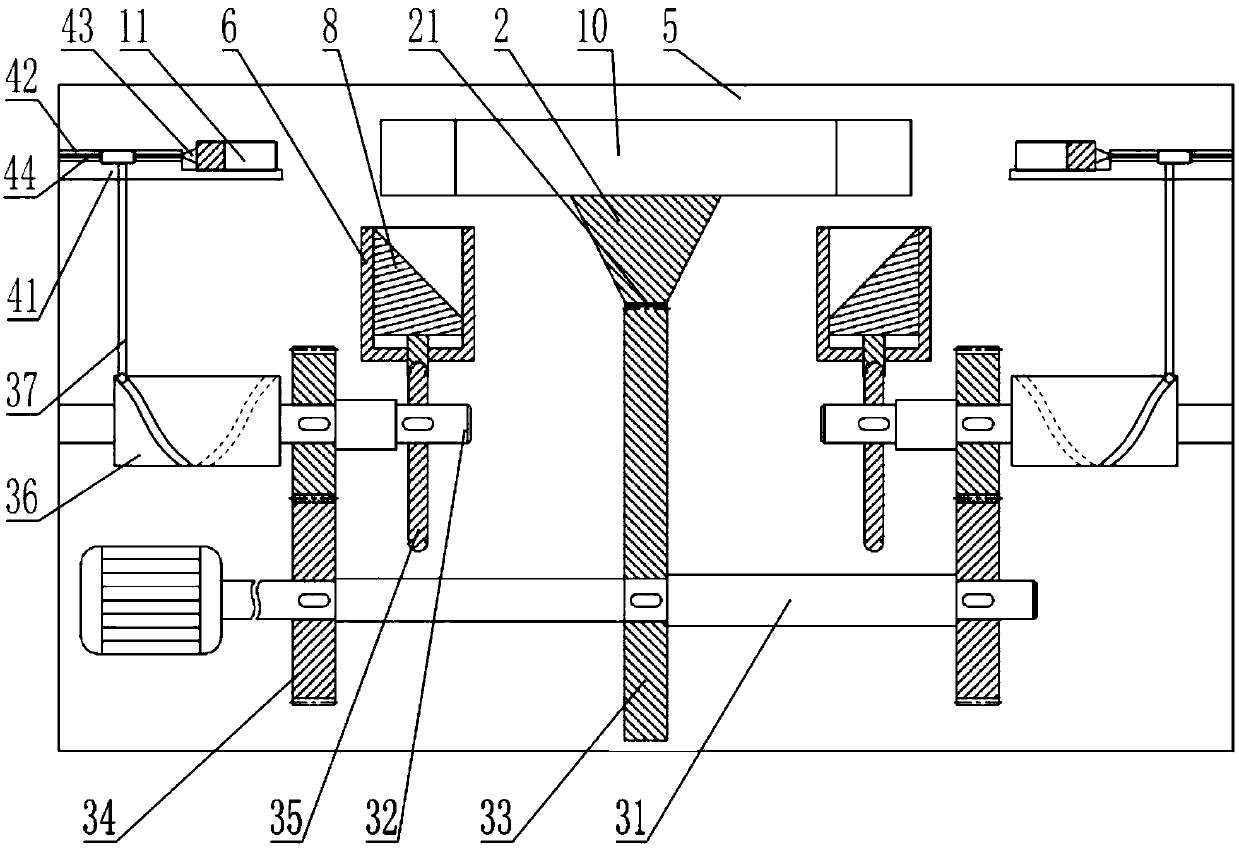

[0023] The reference signs in the drawings of the description include: fixed frame 1, mobile frame 2, transmission part 3, feeding part 4, frame 5, glue barrel 6, spring 7, glue stick 8, left and right outer frames 9, Upper and lower outer frames 10, bumper 11, limit block 12, rack 21, driving shaft 31, driven shaft 32, sector gear 33, cylindrical gear 34, disc cam 35, cylindrical cam 36, moving rod 37 , slide rail 41, hollow slide bar 42, sucker 43, air pipe 44.

[0024] The embodiment is basically as figure 1 with figure 2 Shown:

[0025] Such as figure 1 As shown, the component assembly system of door and window panels includes a fixed frame 1, a symmetrically arranged mobile frame 2 and a transmission part 3, a feeding part 4, a frame 5 and a glue bucket 6, and the fixed frame 1 is provided with symmetrical and identical The spring 7 and the end of the spring 7 away from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com