Wind distributor capable of adjusting wind direction

An air separator and wind direction technology, which is used in solid separation, chemical instruments and methods, and separation of solids from solids by air flow, can solve the problems of inability to adjust, narrow application area, etc., and achieve the effect of uniform blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

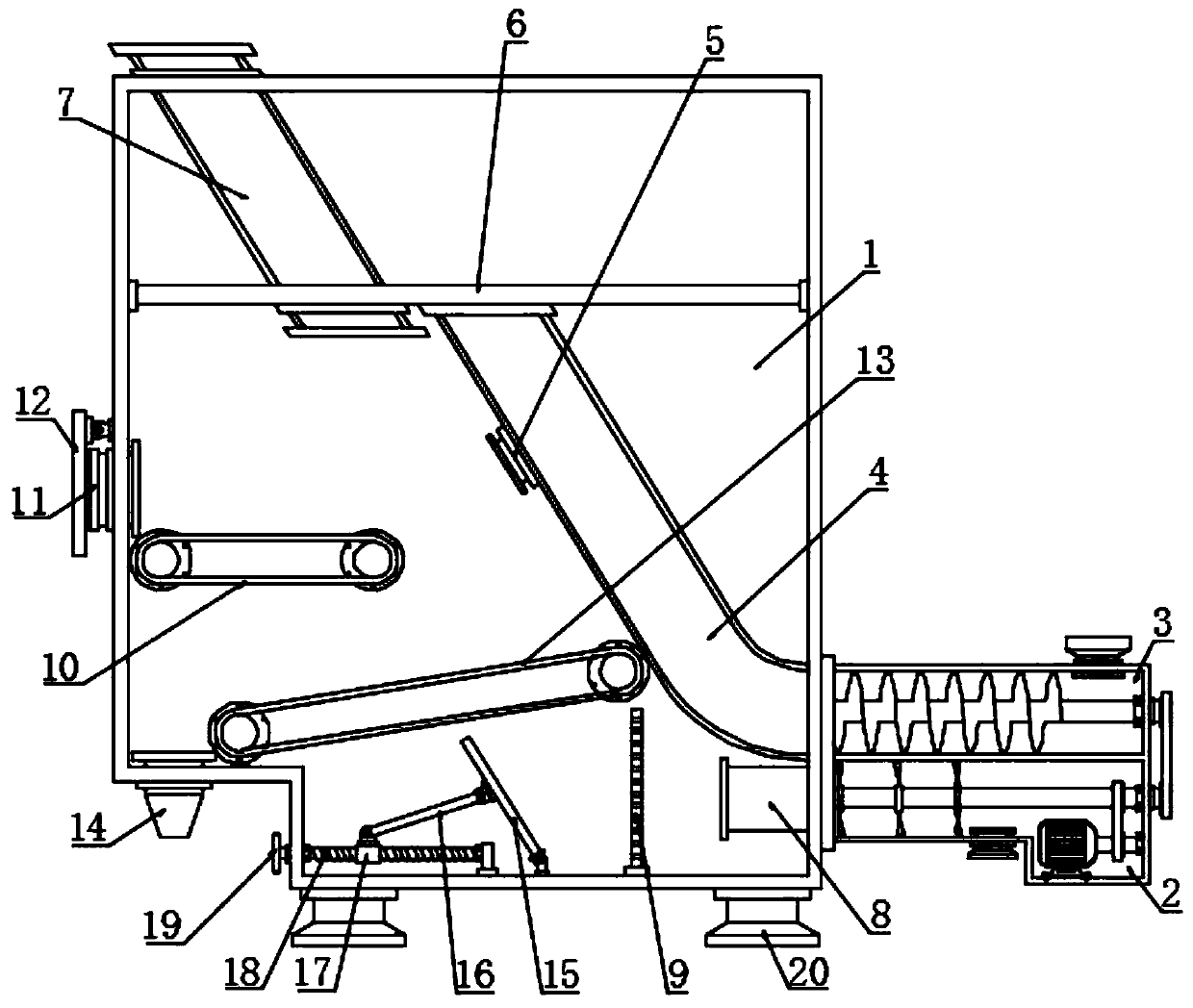

[0021] see Figure 1~3 , in an embodiment of the present invention, an air separator with adjustable wind direction includes an air separator body 1, the lower part of the air separator body 1 is fixedly connected with an air inlet bin 2, and the upper part of the air inlet bin 2 is provided with a feed bin 3, The silo 3 is connected to the conveying channel 4, the upper end of the conveying channel 4 is fixed on the partition plate 6, the partition plate 6 fixes the inner wall of the air separator body 1, and the upper part of the conveying channel 4 is provided with a discharge port 5, which passes through the air inlet bin 2 to the air separator. Air is blown into the air separator body 1 to form a wind flow, and the leaf material is conveyed upwards through the conveying channel 4 by the feed bin 3 and discharged from the discharge port 5; Two conveyor belts 13, it should be noted that both the first conveyor belt 10 and the second conveyor belt 13 are driven by a motor, t...

Embodiment 2

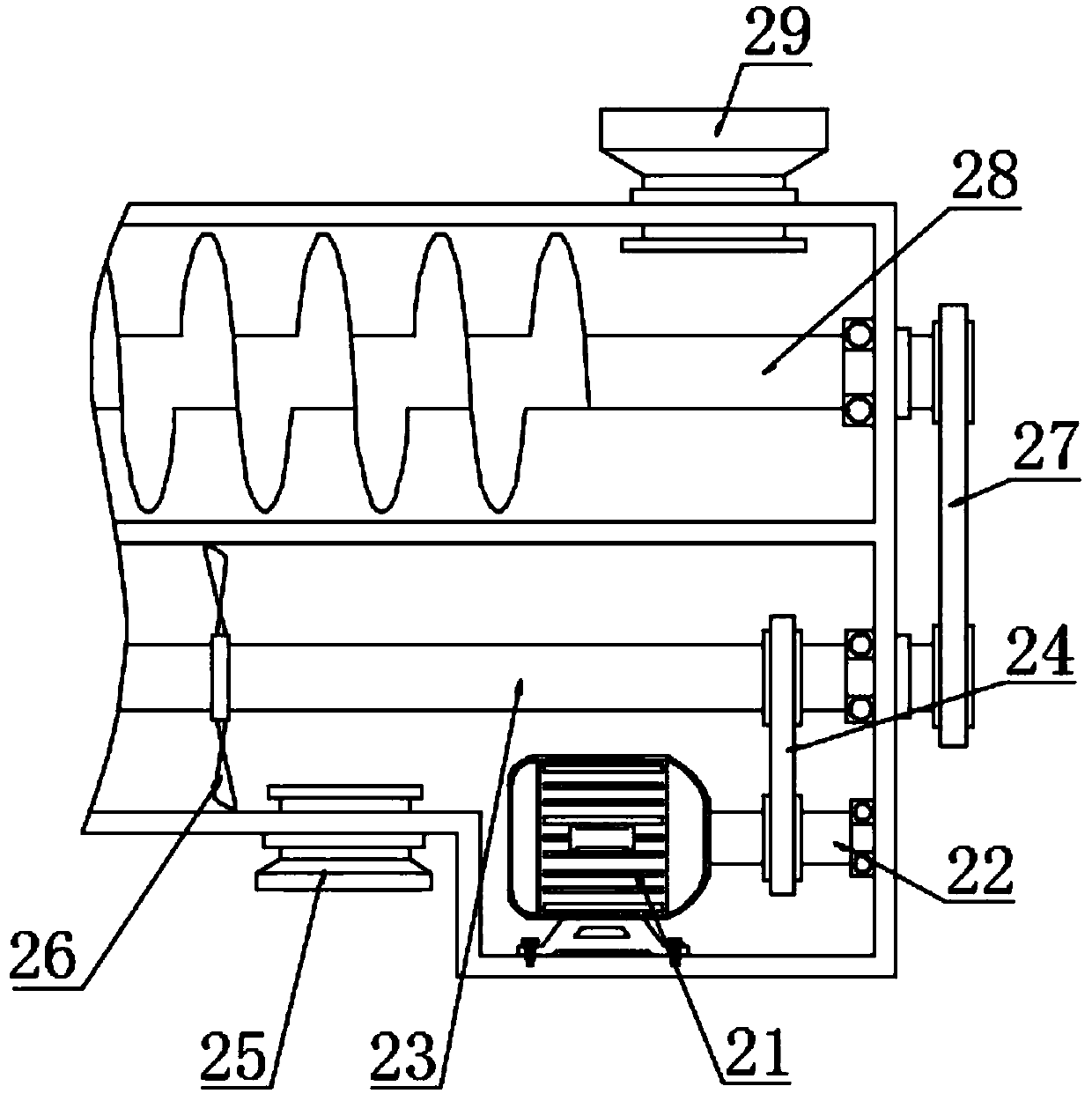

[0025] In order to make the technical solutions in this application more detailed and complete, now some supplements and explanations are made on the basis of the above-mentioned embodiment 1, so that the disclosure of the technical means adopted in this application is more sufficient, specifically, the supplements and explanations Part of the technical feature is that a drive motor 21 is fixedly installed in the air inlet chamber 2, the output end of the drive motor 21 is connected to the output shaft 22, the bearing at the end of the output shaft 22 is connected to the inner wall of the air inlet chamber 2 in rotation, and the lower part of the air inlet chamber 2 is opened There is an air inlet 25, and the inside of the air inlet chamber 2 is rotatably connected with an air supply shaft 23, and a plurality of fans 26 are fixedly connected to the air supply shaft 23, and the air supply shaft 23 and the output shaft 22 are connected by a first synchronous belt 24, and the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com