Automatic shell washing equipment

A shell, automatic technology, applied in the fields of botany equipment and methods, horticulture, plant cultivation, etc., can solve the problems of low degree of automation, low survival rate of seedlings, low washing efficiency, etc., and achieves high degree of automation, high survival rate of seedlings, Efficient flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

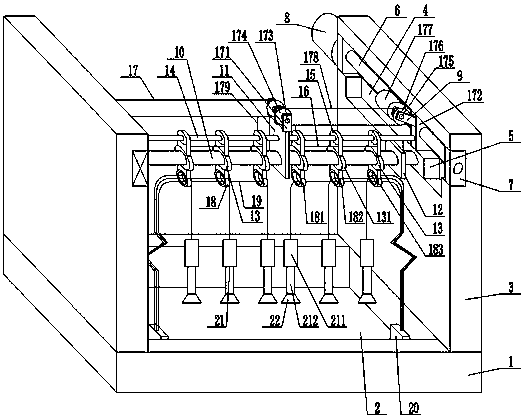

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0009] Such as figure 1 As shown, the automatic shell washing equipment includes: a ground 1 and a seedling pond 2 arranged on the ground 1, shells are laid in the seedling pond 2, and walls are symmetrically arranged on the ground 1 on both sides of the seedling pond 2 Body 3, longitudinal chute 4 is arranged symmetrically on both sides of the upper end of said wall body 3, and longitudinal slider 5 is slidably arranged in said longitudinal chute 4, and a longitudinal screw rod is arranged at the upper end of said longitudinal chute 4 6. The two ends of the longitudinal screw 6 are respectively rotated on the wall 3 through the longitudinal bearing seat 7, and one end of the longitudinal screw 6 protruding from the longitudinal bearing seat 7 is connected to the motor shaft of the servo reduction motor 8. The servo d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com