Waste cracking control system

A technology for controlling system and waste, applied in the direction of waste treatment, solid waste removal, etc., can solve the problems of innocuous treatment and recycling, and achieve the effect of reasonable structure design, pollution reduction and environmental pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

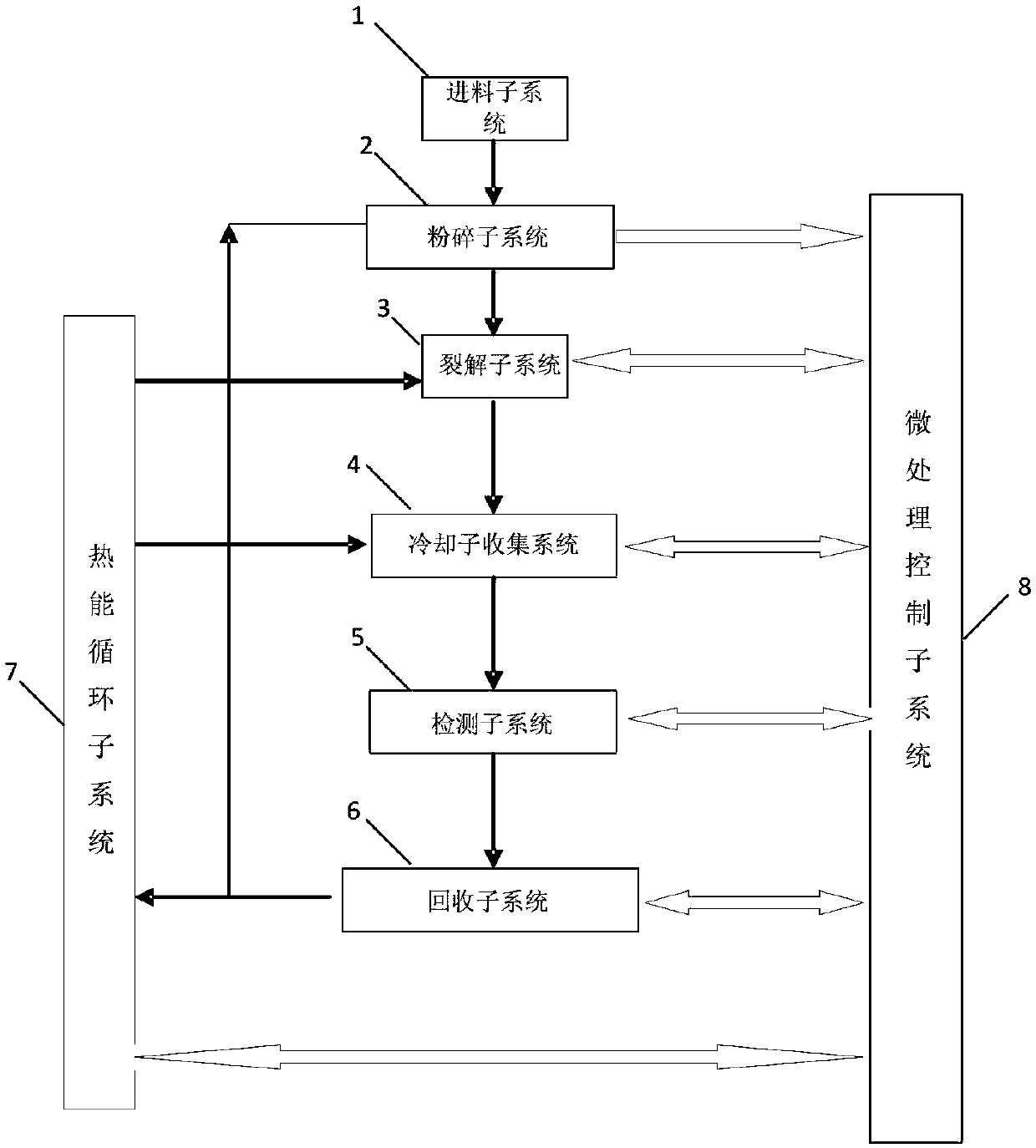

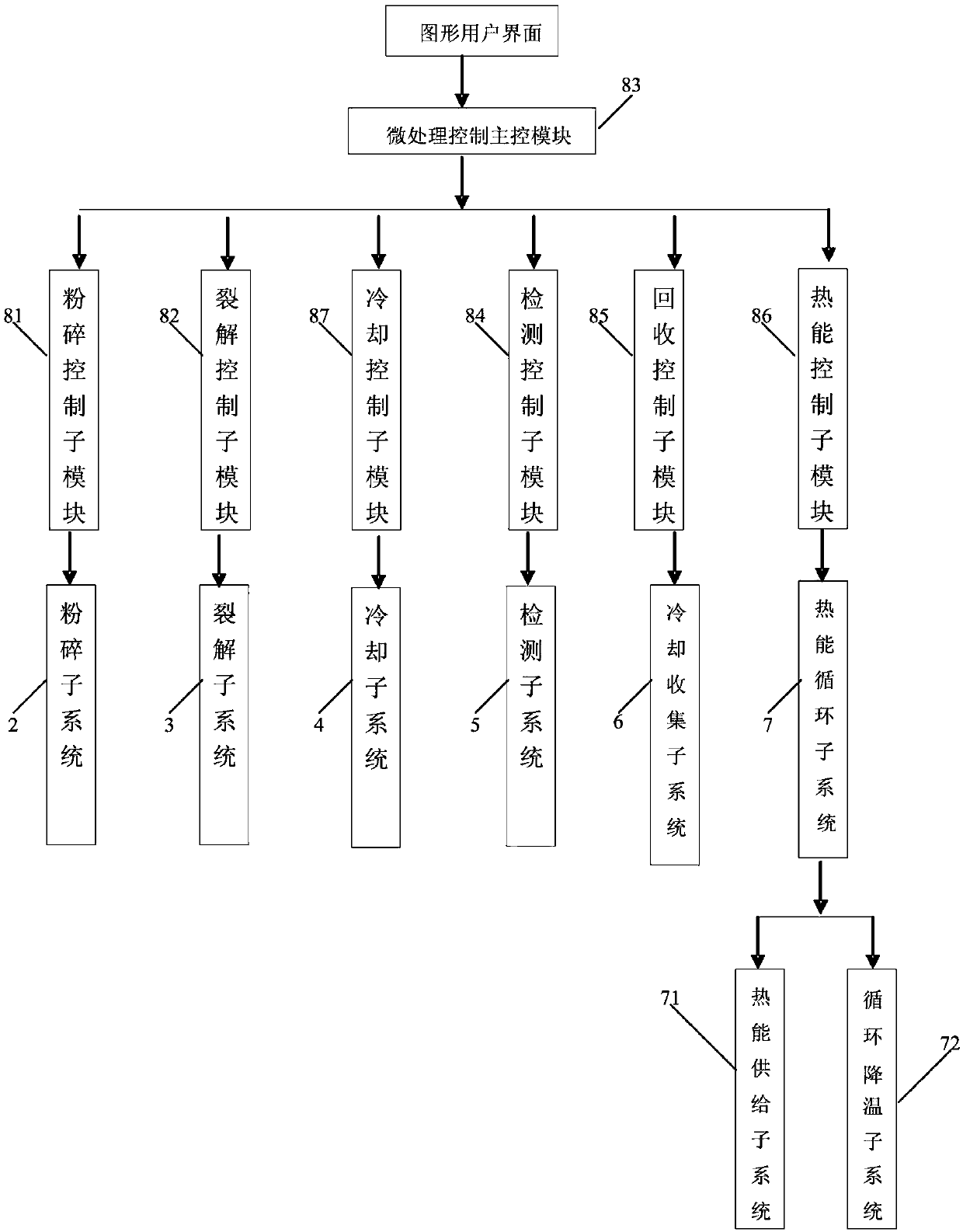

[0036] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, a waste cracking control system includes a feeding subsystem 1, a crushing subsystem 2, a cracking subsystem 3, a cooling sub-collection system 4, a detection subsystem 5, a recovery subsystem 6, a thermal energy circulation subsystem 7 and A micro-processing control subsystem 8, the feed subsystem 1 is connected to the crushing subsystem 2, the cracking subsystem 3, the cooling sub-collection system 4, the detection subsystem 5 and the recovery subsystem 6 pipelines in one direction and in sequence; The thermal energy circulation subsystem 7 directly provides the energy required for cracking for the cracking subsystem 3; the thermal energy circulation subsystem 7 is respectively connected with the recovery subsystem 6 and the cooling sub-collection system 4 pipelines and realizes recycling; the crushing sub-system The feedba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com