Supporting device for superalloy thin-wall thin glass pipe dense array brazing

A support device, technology of superalloys, applied in the field of aerospace science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

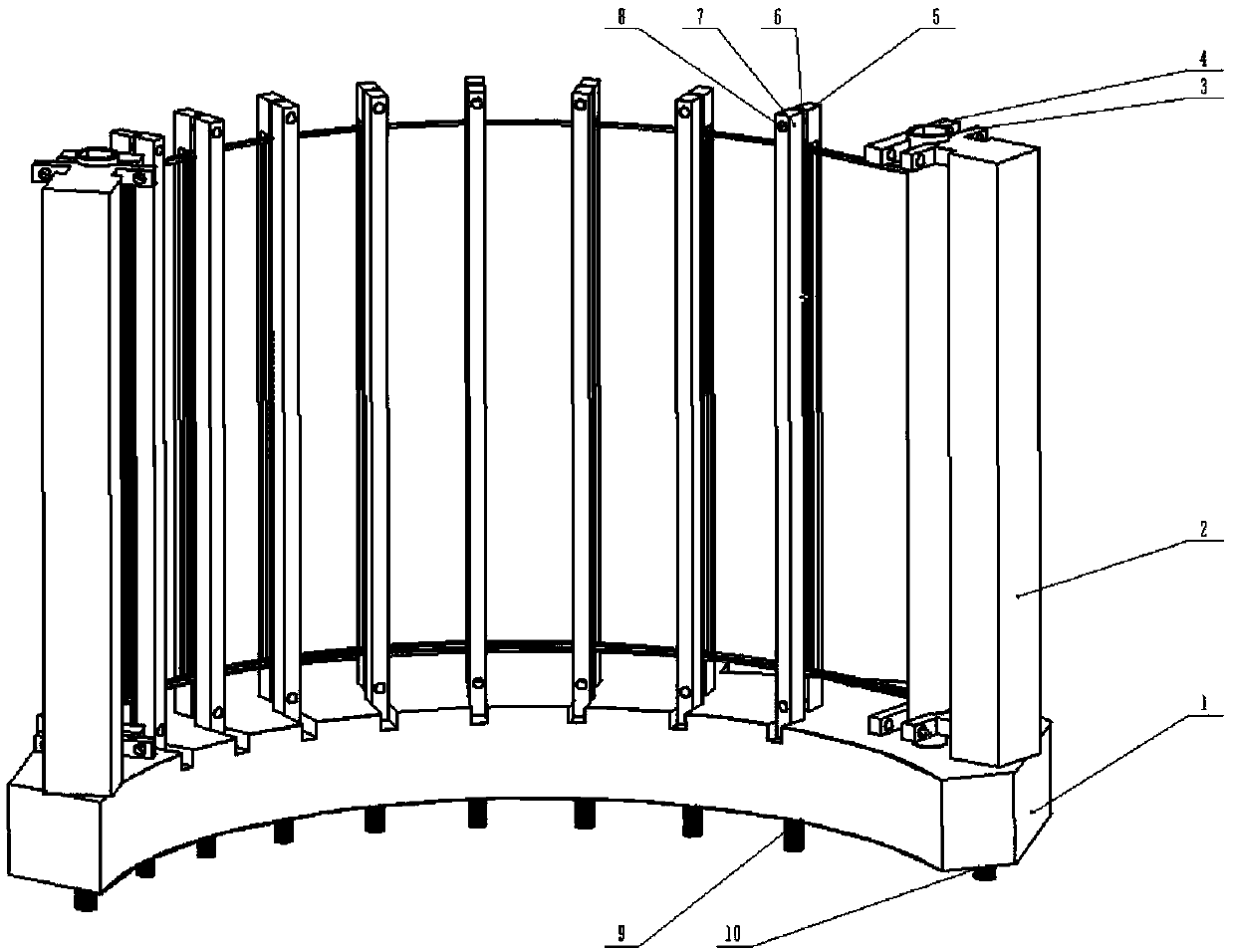

[0027] see figure 1 As shown, an assembly diagram of a support device used for brazing dense arrays of superalloy thin-walled capillaries of the present invention. It is an arc-shaped piece. The supporting device is mainly composed of three parts: a chassis part, a second tube positioning part and a separator positioning part. The position connection relationship between them is: the positioning part of the secondary tube and the positioning part of the partition are located above the chassis part and connected by threads.

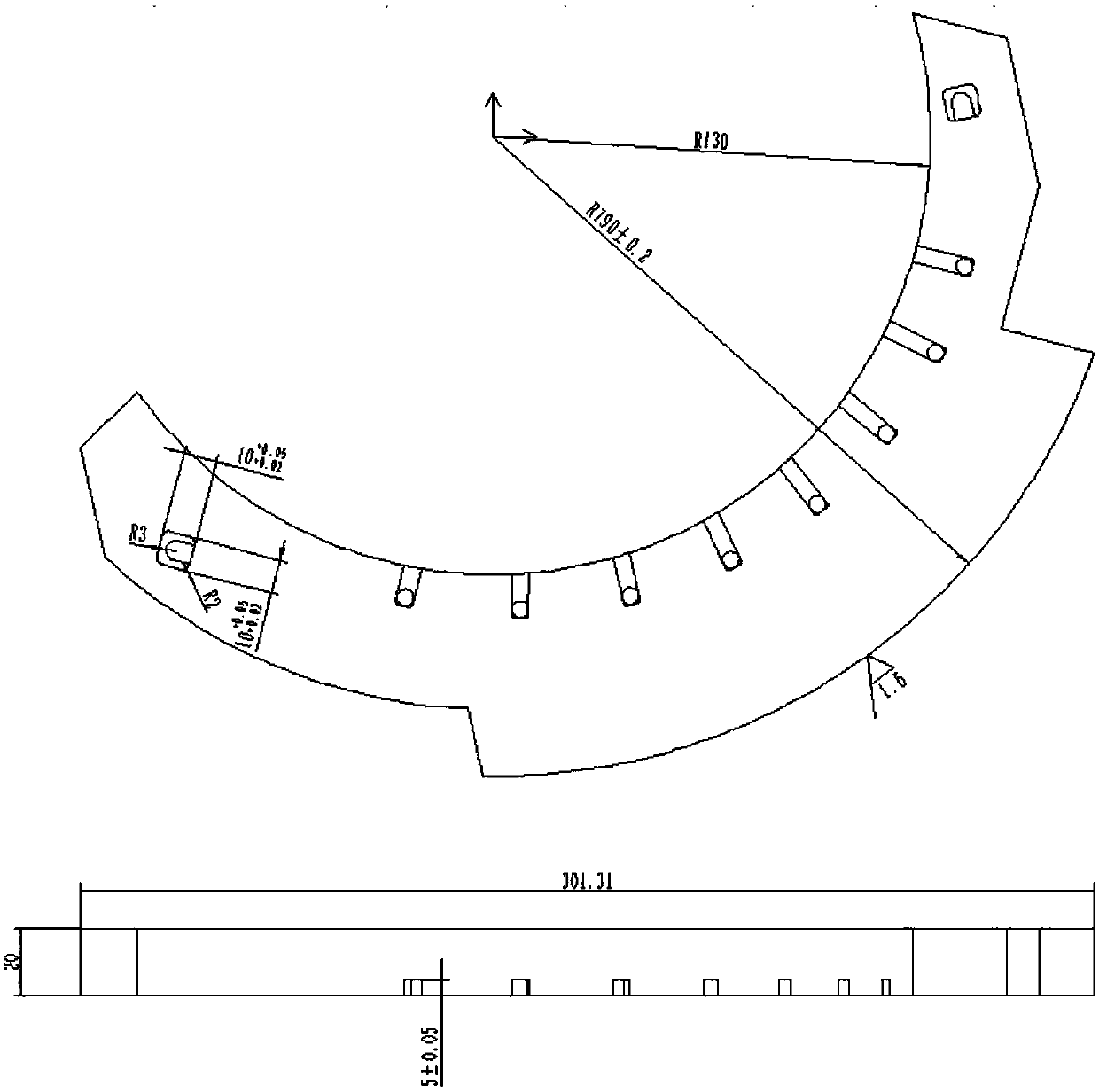

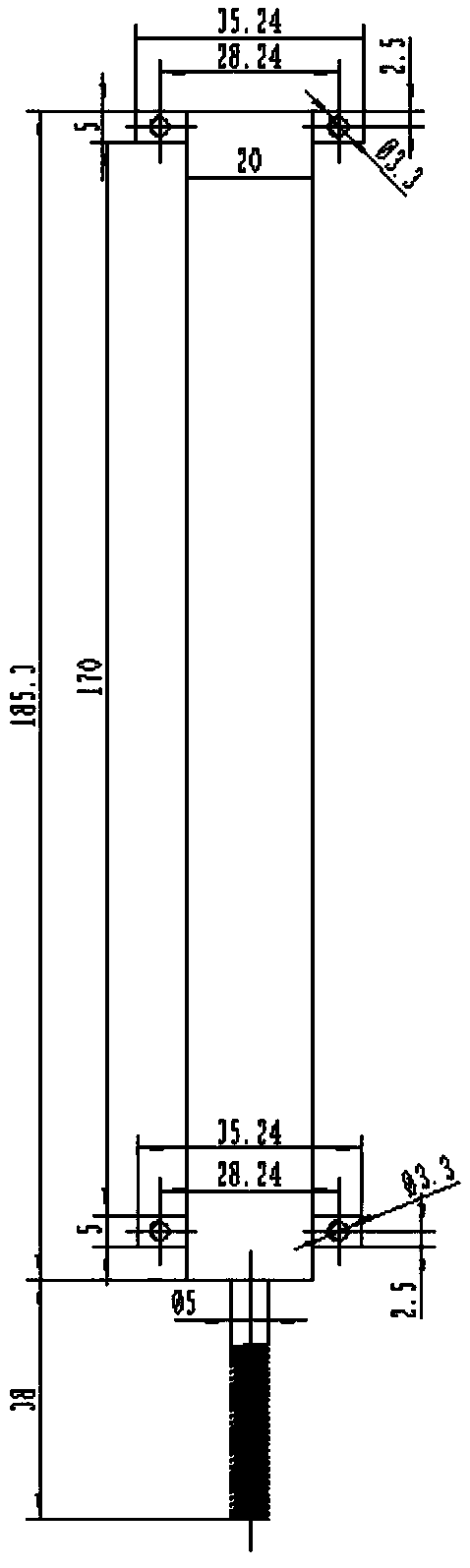

[0028] The chassis part includes a positioning chassis 1 . The structural form of positioning chassis 1 is shown in figure 2 , which can be remanufactured by disc machining: first, the shape of the positioning chassis 1 is cut with the disc axis as the origin coordinate; and then 8 stepped grooves are processed along the thickness direction of the positioning chassis 1. The stepped groove is processed in two steps: the first step is to process a stepp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com