Integrated method and device for detection and assembly of chain cover scattered parts

A chain cover and scattered technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of prolonging the production cycle, increasing the transshipment process, product scrapping, etc., to save cost and time, reduce and outflow risk, The effect of reducing manufacturing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

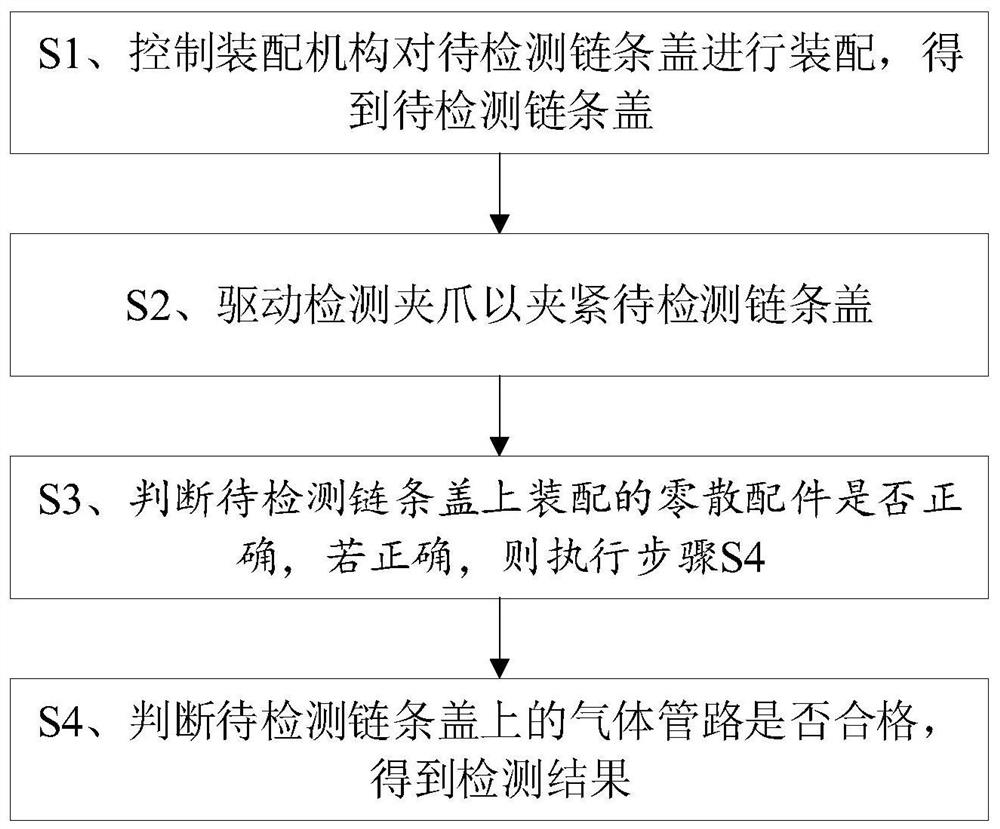

[0048] Such as Figure 1 to Figure 6 As shown, the integrated method for detection and assembly of chain cover loose parts includes the following steps:

[0049] S1. Control the assembly mechanism 4 to assemble the chain cover to be detected to obtain the chain cover to be detected;

[0050] S2. Drive the detection jaws to clamp the chain cover to be detected;

[0051] S3, judging whether the scattered accessories assembled on the chain cover to be detected are correct, if correct, then perform step S4;

[0052] S4, judging whether the gas pipeline 5 on the chain cover to be detected is qualified, and obtaining the detection result.

[0053] It can be seen that the chain cover to be detected is assembled by the assembly mechanism 4, the chain cover to be detected is clamped by the detection jaws to fix the product, and the error proof sensor 24 is used to judge whether the scattered parts assembled on the chain cover to be detected are correct, thereby solving the problem. ...

Embodiment 2

[0083] Such as Figure 1 to Figure 6 As shown, the integrated device 1 for detection and assembly of chain cover spare parts includes a detection mechanism 2 , a main controller 3 and an assembly mechanism 4 .

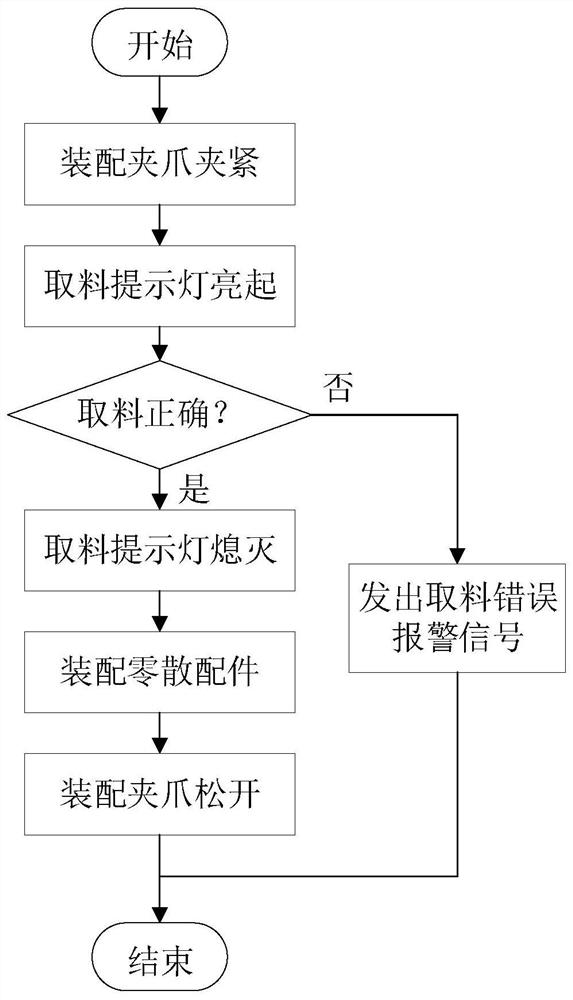

[0084] Wherein, the assembly mechanism 4 includes a first jaw 41 and a second jaw 42 located at two opposite ends of the assembly station 44, a parts retrieval box 43 for one-to-one correspondence with six scattered parts, and a parts retrieval box located in the parts retrieval box. The retrieving detection sensor in 43 and the assembly tool 45; Each parts retrieving box 43 is provided with a retrieving detection sensor;

[0085] Among them, the first clamping jaw 41 and the second clamping jaw 42 are used to clamp the chain cover to be detected; the material retrieving detection sensor is used to detect whether there is a material retrieving action; the assembly tool 45 is used to assemble scattered parts.

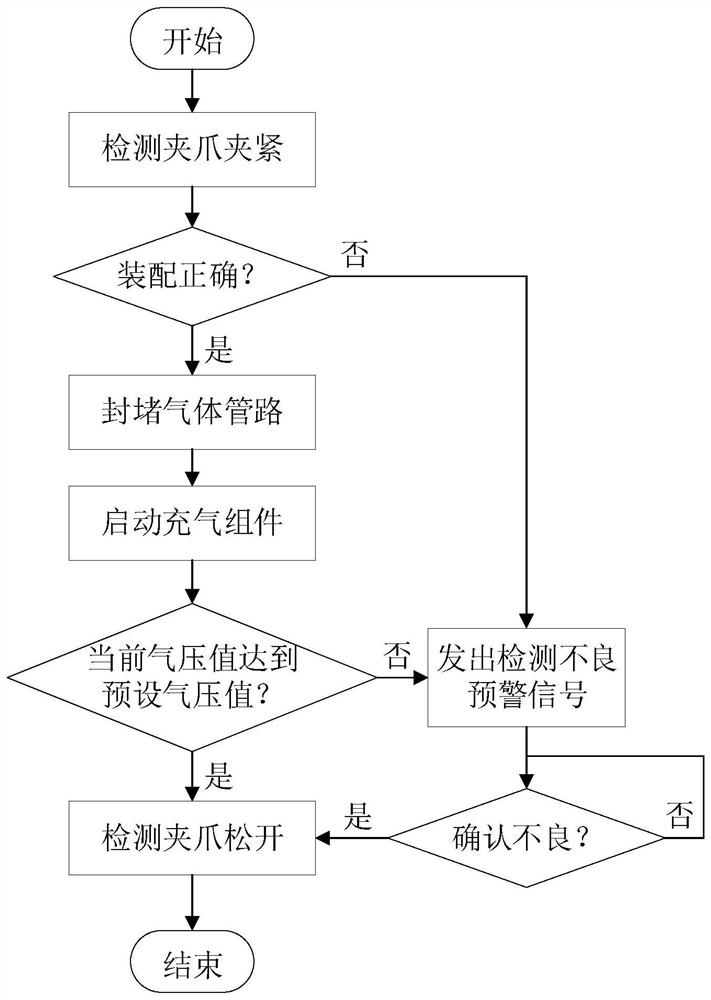

[0086] Wherein, the detection mechanism 2 includes the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com