Memory alloy pin puller

A memory alloy and memory alloy wire technology, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of poor ease of use, complicated heating process, and long response time of pin pullers, and achieves improved ease of use and reliability. Safe and convenient operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

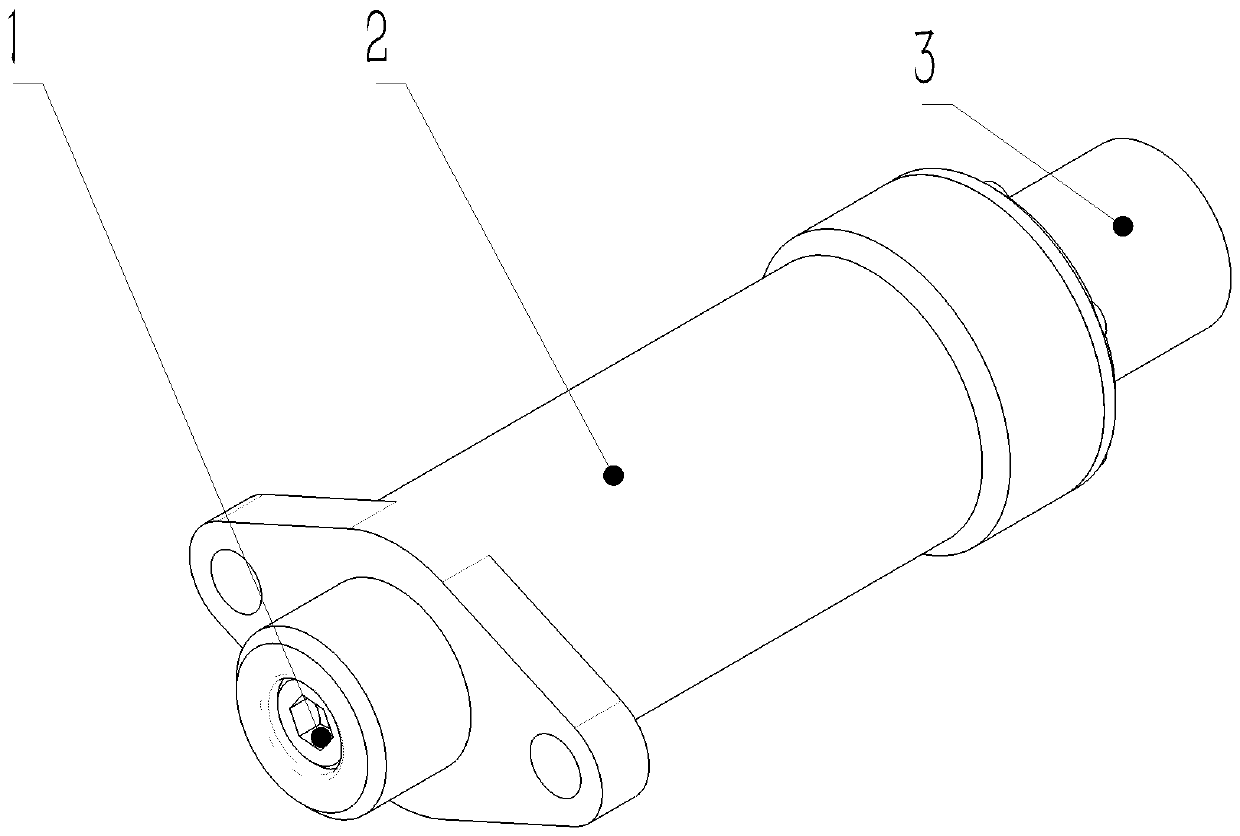

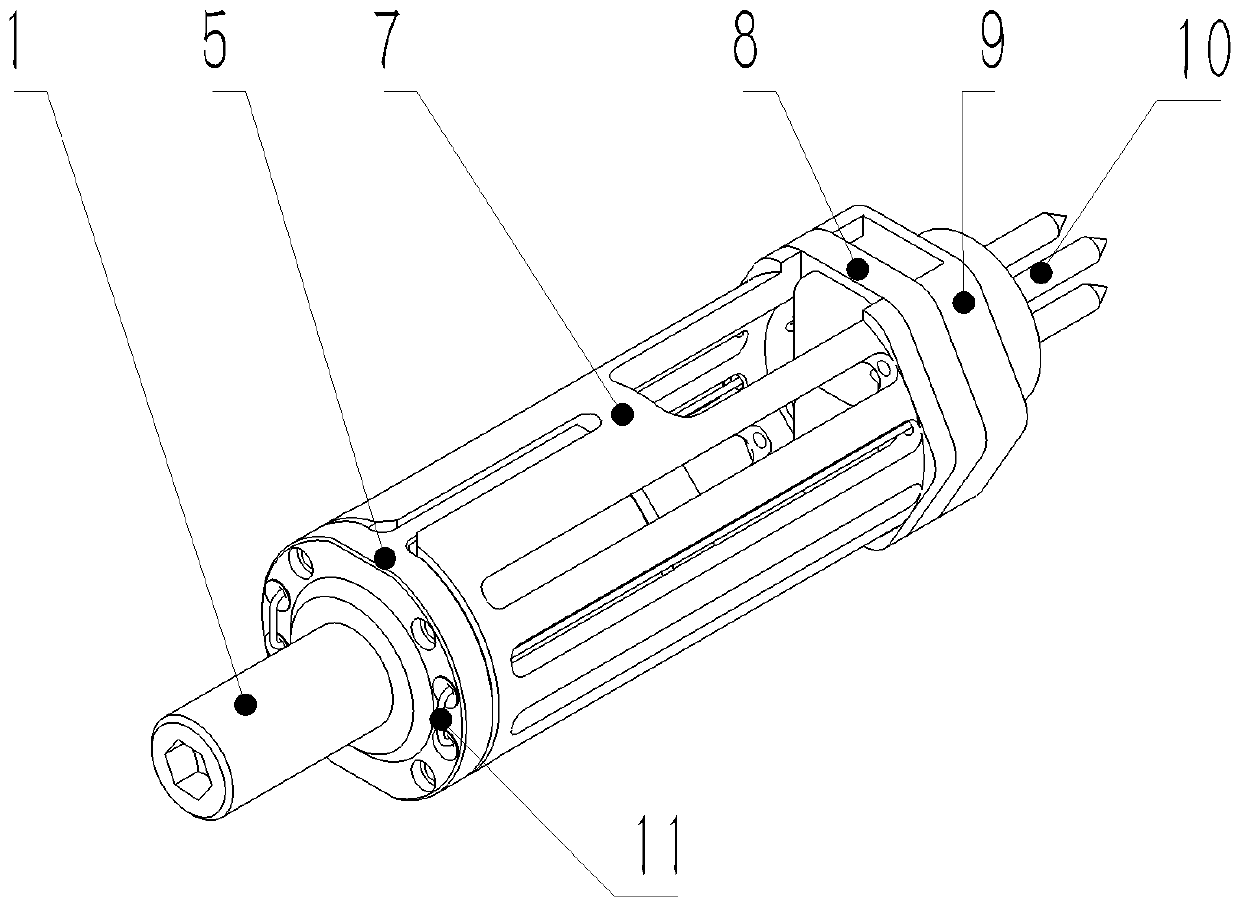

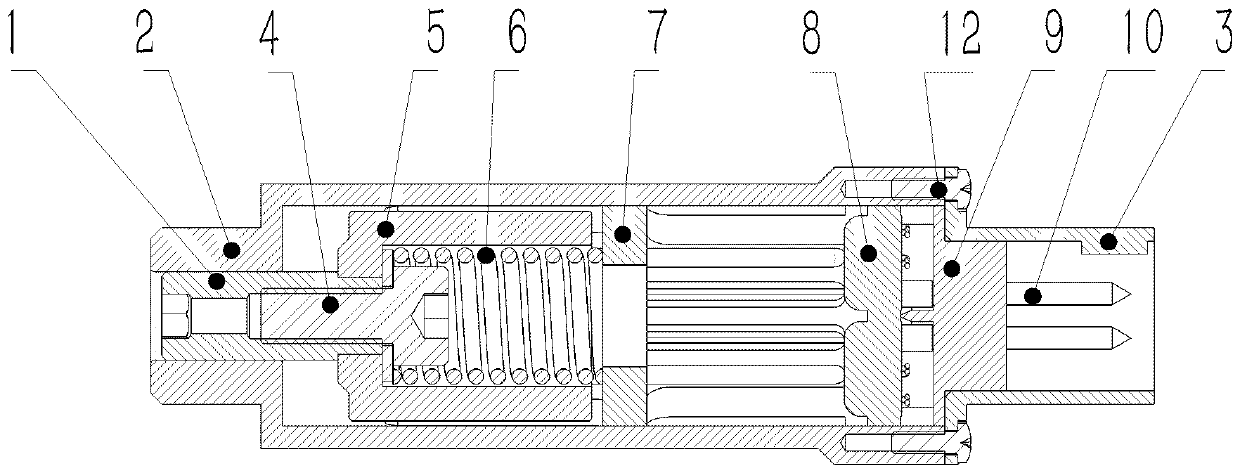

[0028] Such as figure 1 , 2 , 3 and 4, a memory alloy pin puller is characterized in that pin 1, shell 2, electrical connector end cover 3, screw A4, pull plate 5, spring 6, spring sleeve 7, PCB board 8 , insulating end cap 9, connector pin 10, memory alloy wire 11, screw B12;

[0029] The pin 1 is a cylindrical metal part, the outer contour is divided into two sections according to different diameters, a threaded hole is provided in the center of the end surface of the smaller diameter side, and a hexagonal counterbore is provided on the other end surface, and a threaded hole is provided in the center of the counterbore;

[0030] The shell 2 is a cylindrical metal cavity body, and the outer contour is divided into three sections according to different diameters, and the diameters increase successively. A circular hole is provided in the center of the end face of the section with the smallest diameter, and a pair of uniform holes along the circumferential direction are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com