Light-induced mildew-proof bamboo product and preparation method thereof

A light-induced bamboo technology, applied in impregnation of wood, manufacturing tools, wood impregnation, etc., can solve the problems of easy mildew, difficult operation, cumbersome operation process, etc., to solve mildew, mild reaction conditions, and simple operation process Feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

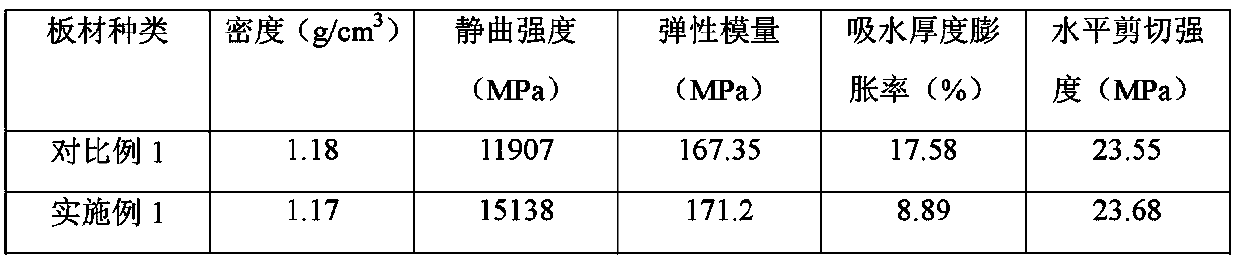

Embodiment 1

[0044] Taking 120°C lightly carbonized bamboo bundles to make bamboo boards as an example, the preparation method of a light-induced mildew-resistant bamboo product in this embodiment includes the following steps:

[0045] (1) Preparation of lightly carbonized bamboo bundles.

[0046] (2) Immerse the bamboo bundles in a 0.4 mg / mL dopamine solution adjusted to a pH of about 8.5 with Tris buffer solution for 60 minutes, take it out and drain until no solution drips, and then dry it at 70°C for 40 minutes to obtain polydopamine-covered membranes. Bamboo bundles.

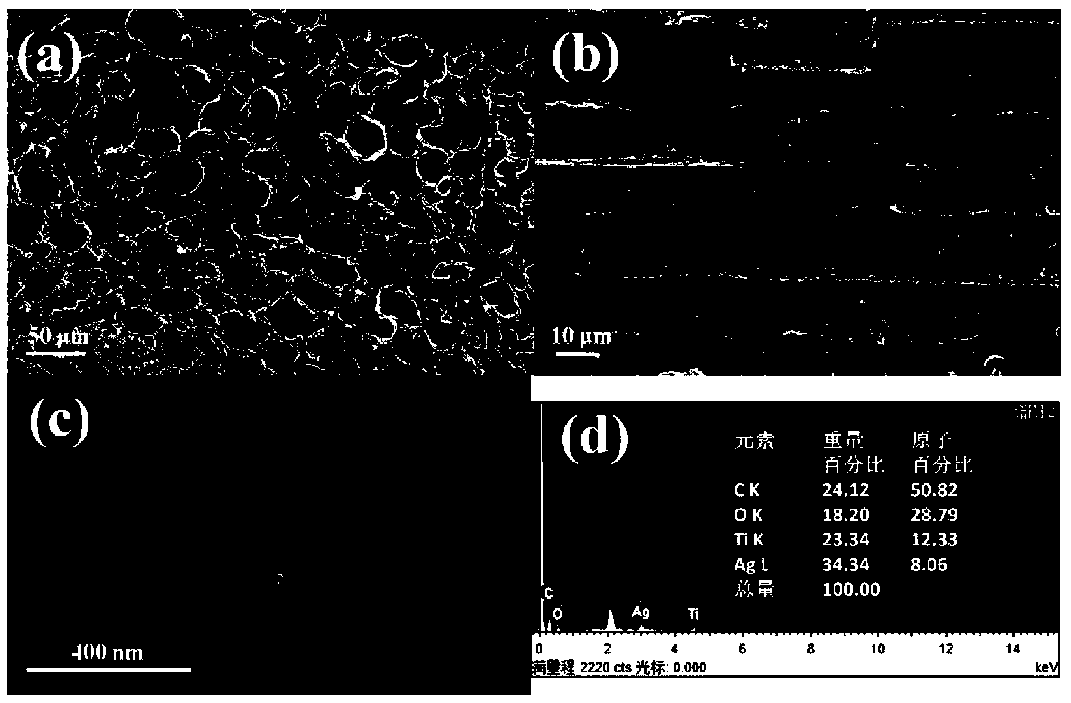

[0047] (3) Soak bamboo bundles covered with polydopamine film in 0.01mol / L titanyl sulfate solution for 120 minutes, take it out and add ammonia water (in other embodiments, sodium hydroxide solution can be used) to adjust the pH value to 9 , after adjusting the pH value, remove and drain until no solution drips, and dry at 70°C for 60 minutes to obtain loaded TiO 2 bamboo bunches.

[0048] (4) will load TiO 2 Bambo...

Embodiment 2

[0060] A kind of preparation method of light-induced mildew-proof bamboo product of the present embodiment, comprises the following steps:

[0061] (1) Coat the surface of lightly carbonized recombined bamboo purchased from the market with a 0.4mg / mL dopamine solution with a pH value of about 8.5 adjusted by Tris buffer solution, and dry it at 70°C after the coating is not sticky After 40 minutes, the recombined bamboo covered with the polydopamine film was obtained.

[0062] (2) After the recombined bamboo coated with polydopamine film 3 times is coated with 0.01mol / L titanyl sulfate solution, then coated with ammonia water (in other embodiments, sodium hydroxide solution can be used), and use pH test paper to detect The surface of the restructured bamboo is coated with the mixed liquid until the pH value is 9. After the coating is not sticky, it is dried at 70°C for 60 minutes to obtain the loaded TiO 2 recombined bamboo.

[0063] (4) will load TiO 2 After the recombined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com