Efficient injection molding mechanical hand

A manipulator and high-efficiency technology, applied in the field of high-efficiency injection molding manipulators, can solve the problems of insufficient protection, low use efficiency, and insufficient manipulator flexibility, and achieve the effects of good self-protection, high use efficiency, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

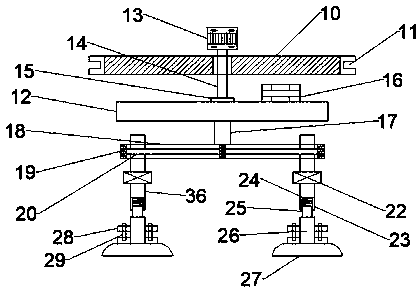

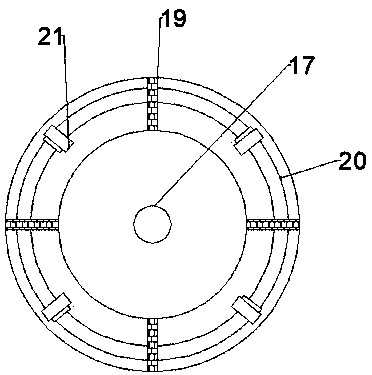

[0019] see Figure 1-3 , a high-efficiency injection molding manipulator, including a mounting plate 10, the left and right sides of the mounting plate 10 are provided with mounting openings 11, through which the entire manipulator can be installed at the position to be used. A rotating motor 13 is provided at the top middle position of the mounting plate 10, and the lower output end of the rotating motor 13 is rotatably connected with a vertical rotating rod 14, and the bottom end of the rotating rod 14 is fixedly equipped with a turntable 15, and the bottom end of the turntable 15 is A placement board 12 is fixedly installed, and a tool cabinet 16 is fixedly placed on one side of the top of the placement board 12. The setting of the tool cabinet 16 can provide some convenience for the staff. A connecting rod 17 is fixedly connected to the center of the bottom of the placement plate 12 , and a circular mounting frame 18 is fixedly connected to the bottom end of the connecting...

Embodiment 2

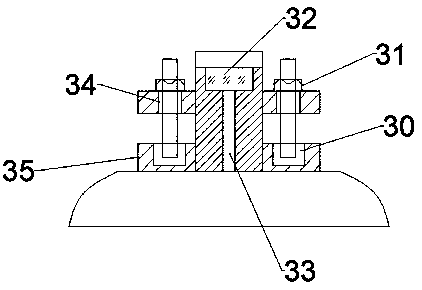

[0022] On the basis of Embodiment 1, an air conditioner 32 is provided on the inner top of the mounting seat 26, and the lower side of the air conditioner 32 is communicated with a cold air pipe 33, and the end of the cold air pipe 33 extends into the inner top of the suction cup 27. The cold air produced by the air conditioner 32 is transported to the inside of the suction cup 27 by the cold air pipe 33 to cool down the forming mold to be adsorbed, so as to prevent the service life of the suction cup 27 from being damaged due to the high temperature of the product to be adsorbed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com