Multi-layer driving anti-slip control method suitable for electric wheel driving vehicle

A control method and electric wheel technology, applied in electric vehicles, control drives, control devices, etc., can solve problems such as high processor computing performance requirements, sacrificing vehicle performance, and difficult engineering implementation, so as to reduce impact, Improved stability, working reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

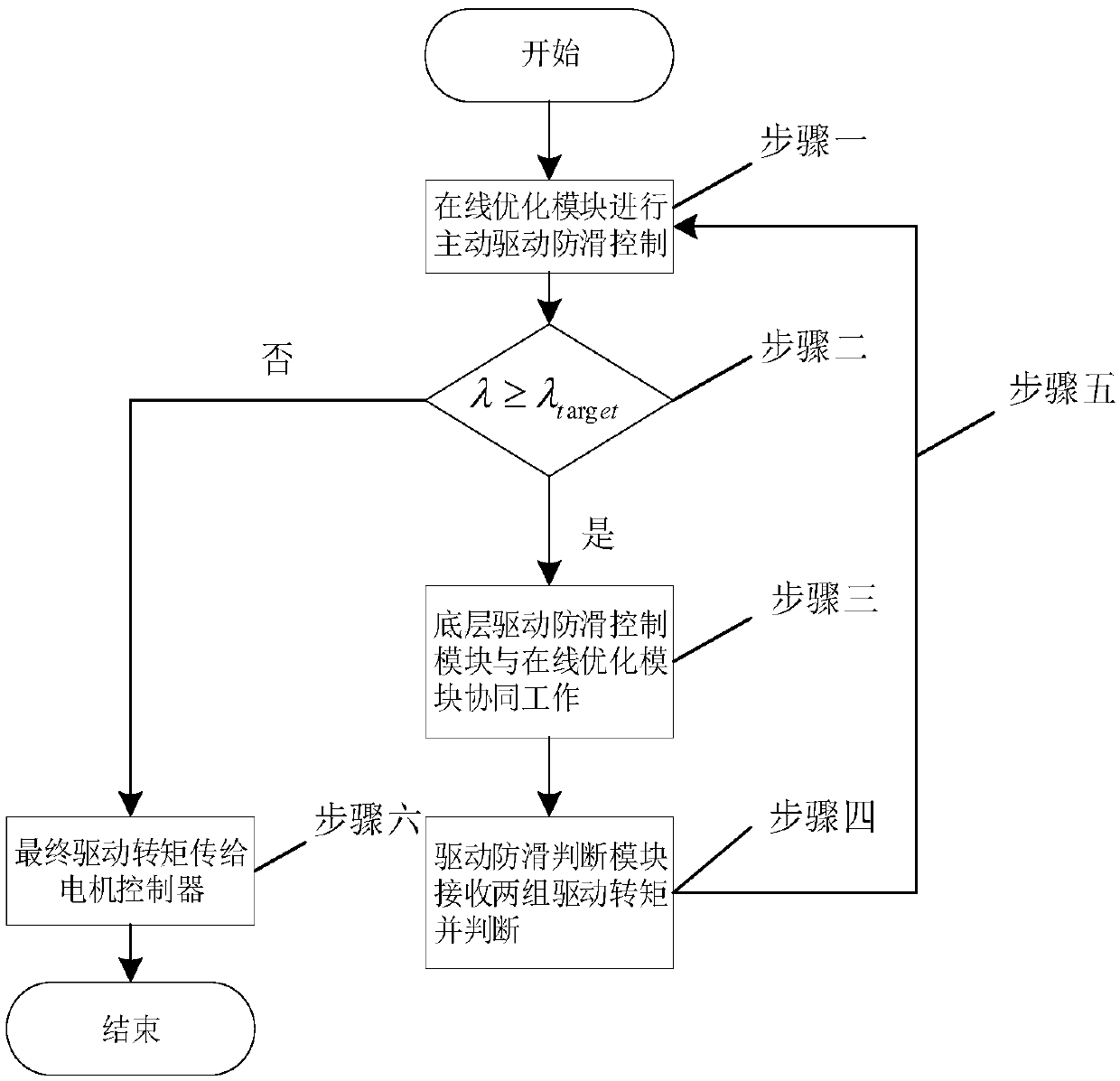

[0064] Such as figure 1 As shown, the present invention provides a multi-layer drive anti-skid control method suitable for electric wheel-driven vehicles, through the cooperative work of the three modules of the driving force online optimization module, the bottom-level drive anti-skid control module and the drive anti-skid judgment module, to achieve The purpose of controlling the wheel slip and improving the stability of the vehicle.

[0065] The described multi-layer drive anti-skid control method applicable to electric wheel drive vehicles comprises the following steps:

[0066] Step 1. When the electric wheel drive vehicle is running normally, the online optimization module performs active drive anti-skid control. The vehicle is distributed according to the driving tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com