AGV drive with lifting function and AGV trolley

A function and lifting block technology, applied in the field of AGV trolley, can solve the problems of cumbersome installation and debugging process, complex structure, etc., and achieve the effect of easy control and debugging, simple cooperation and improved resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

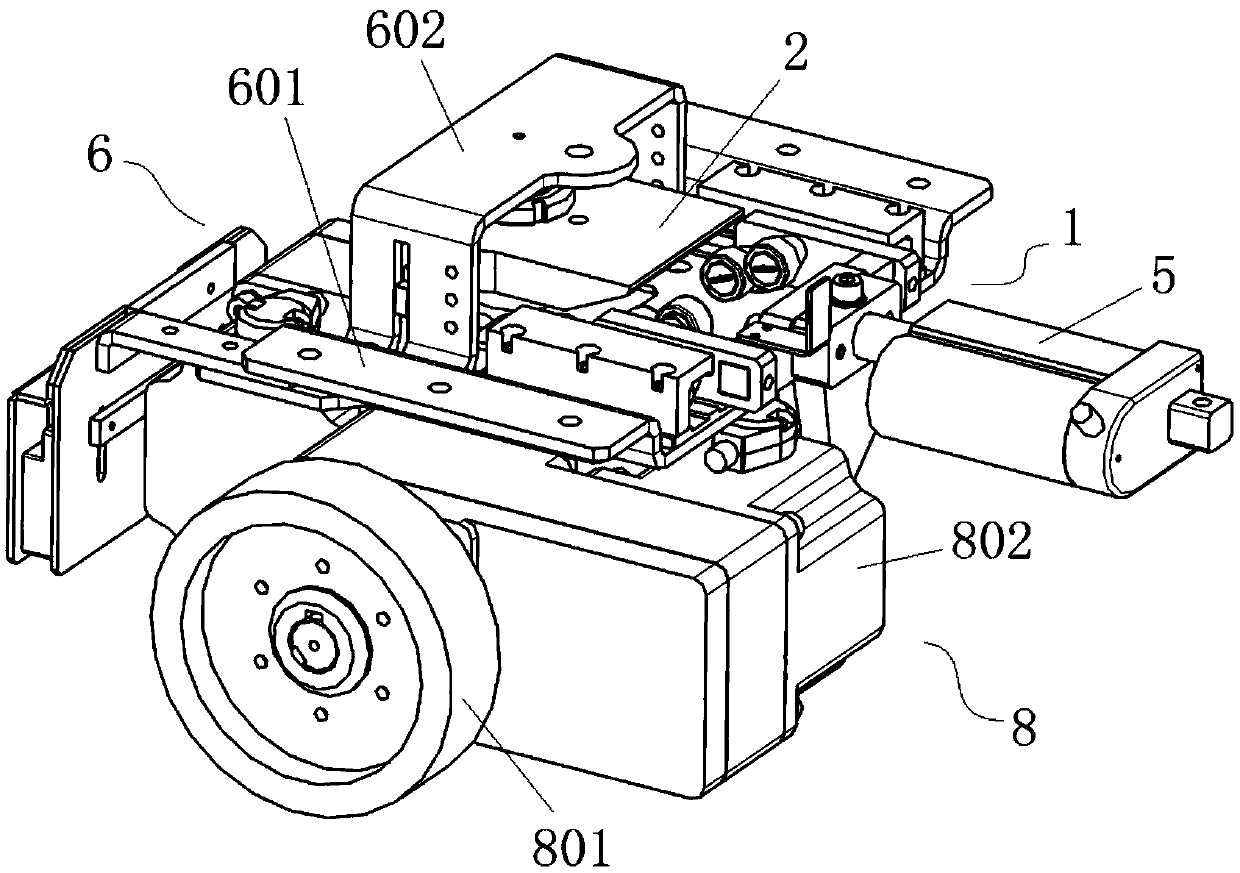

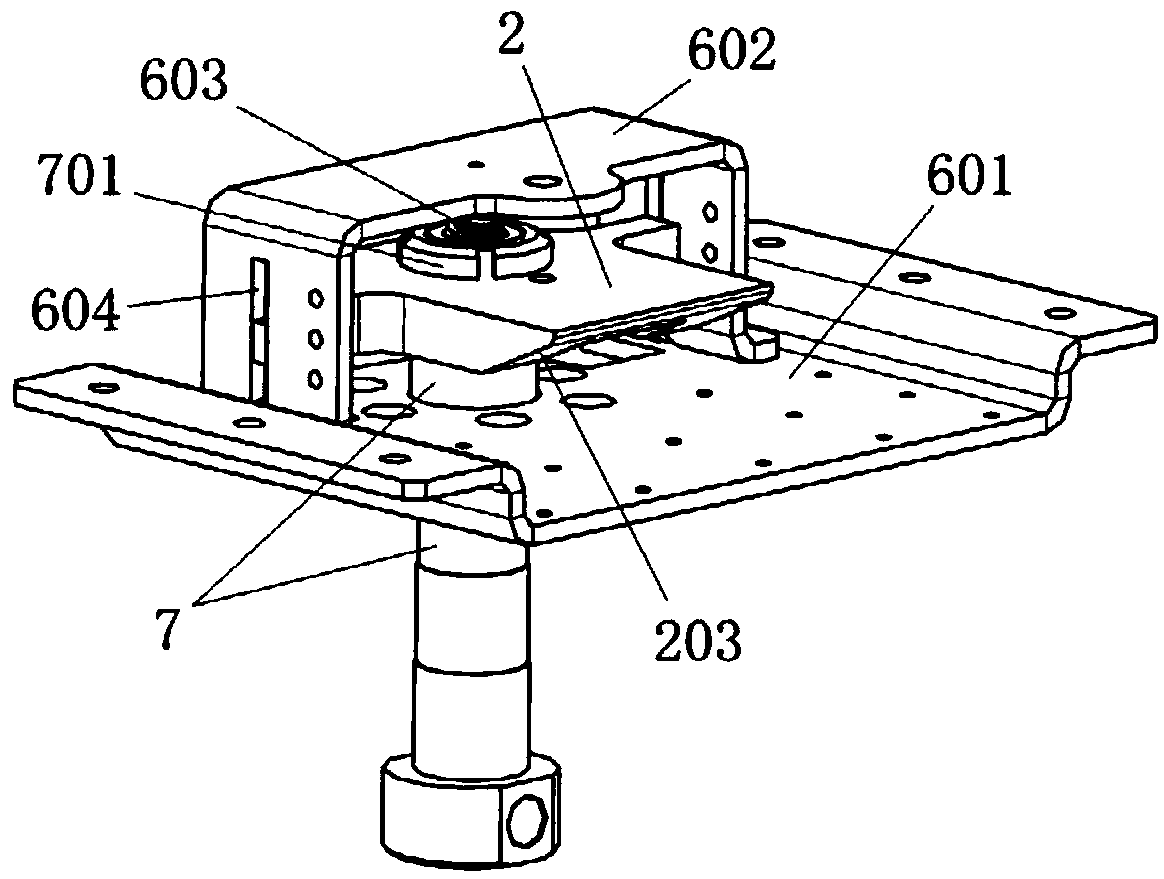

[0056] This embodiment provides a kind of AGV driver with lifting function, such as figure 1 As shown, it includes the driving body 6 and the lifting part 1, and the lifting part 1 is connected to the fixed mounting plate 601 of the driving body 6. The figure shows that the lifting part 1 does not lift the driving body. At this time The driving supporting wheel 801 of the driving body 6 can be in reliable contact with the ground.

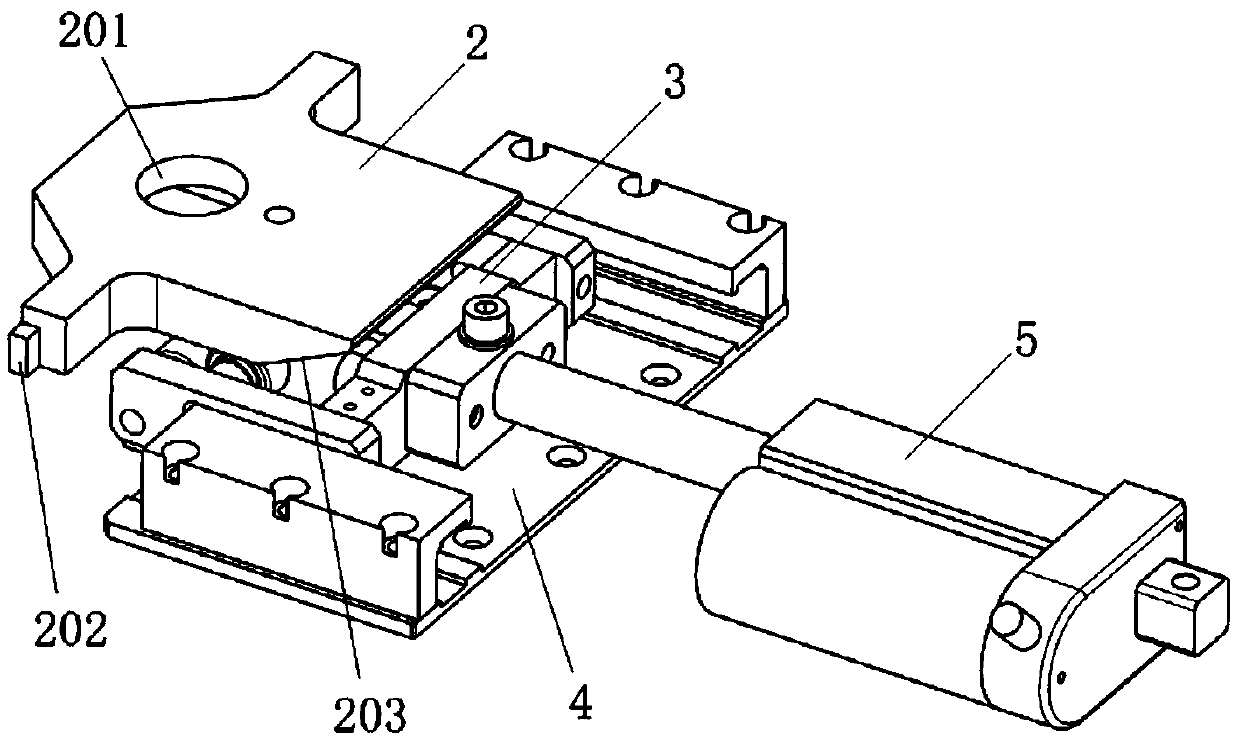

[0057] Such as figure 2 As shown, the lifting part 1 includes: a lifting block 2, a cam follower assembly 3, a cam support plate 4 and a push rod 5, and the lifting block 2 has a through hole 201 for connecting with the driving body 6, and The inserting block 202 for inserting into the sliding groove 604 and the inclined surface 203 for contacting the cam follower assembly 3, the inserting block 202 is provided with two symmetrically on the lifting block 2; the cam When the follower assembly 3 moves laterally toward the lifting block 2 along the ...

Embodiment 2

[0067] This embodiment provides an AGV trolley with the AGV drive described in Embodiment 1, the AGV drive has at least four, which are respectively arranged at the four sides / corners at the bottom of the AGV trolley, so as to support and drive the AGV trolley.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com