A loading device for carrying objects and a shock-absorbing packaging method for carrying objects

A packaging method and load technology, applied in transportation and packaging, space navigation equipment, space navigation aircraft, etc., can solve the problems of high cost, unstable fixation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

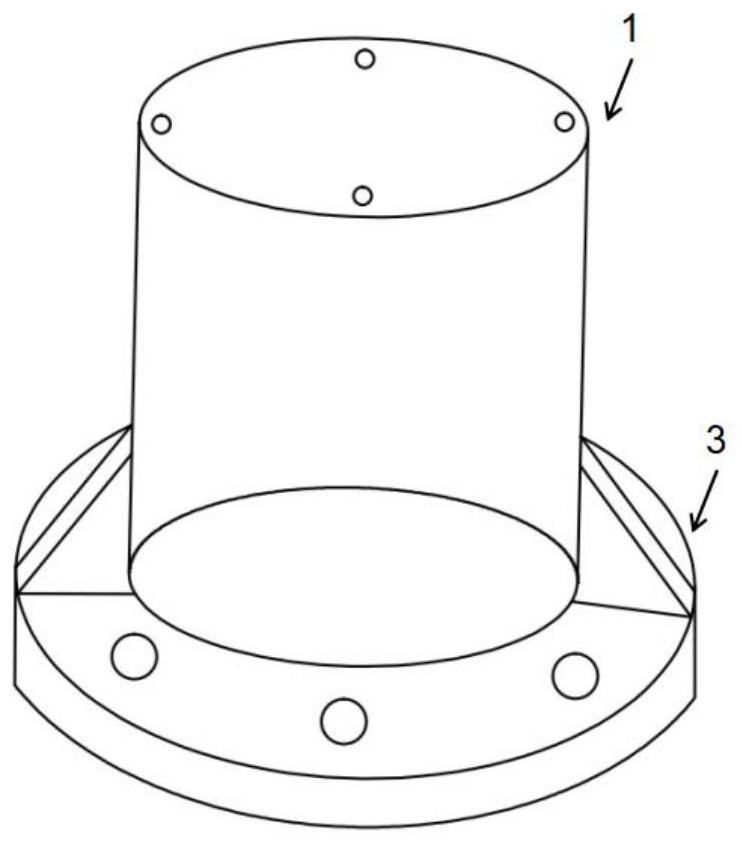

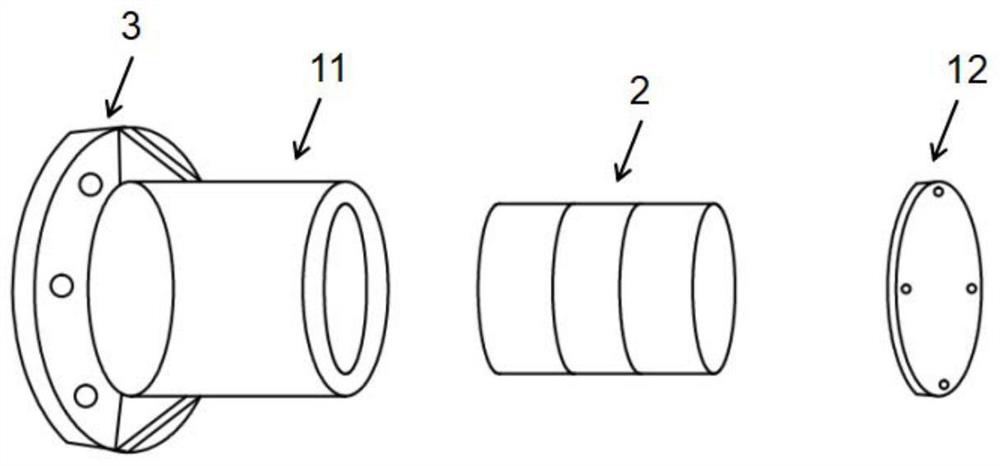

[0052] Please refer to Figure 1 to Figure 5 , the present invention provides a loading device, comprising:

[0053] The casing 1 is cylindrical, and the casing 1 includes a casing 11 and a casing cover 12. The casing 11 and the casing cover 12 are arranged to facilitate the assembly of the shock absorber 2 and the carrying objects;

[0054] The casing 11 and the casing cover 12 are connected by connecting pieces, and the four corners of the mating surface of the casing 11 and the casing cover 12 are provided with threaded holes, and the corresponding four corners of the casing cover 12 are also provided with threads. Holes, the shell 11 and the shell cover 12 can be connected by screws;

[0055] The space carrying object loading device also includes a shock absorbing body 2, which is a thermoplastic polyolefin elastomer, and the carrying object is wrapped therein. The method for wrapping the carrying object is to mix the thermoplastic elastomer with the inert gas under the e...

Embodiment 2

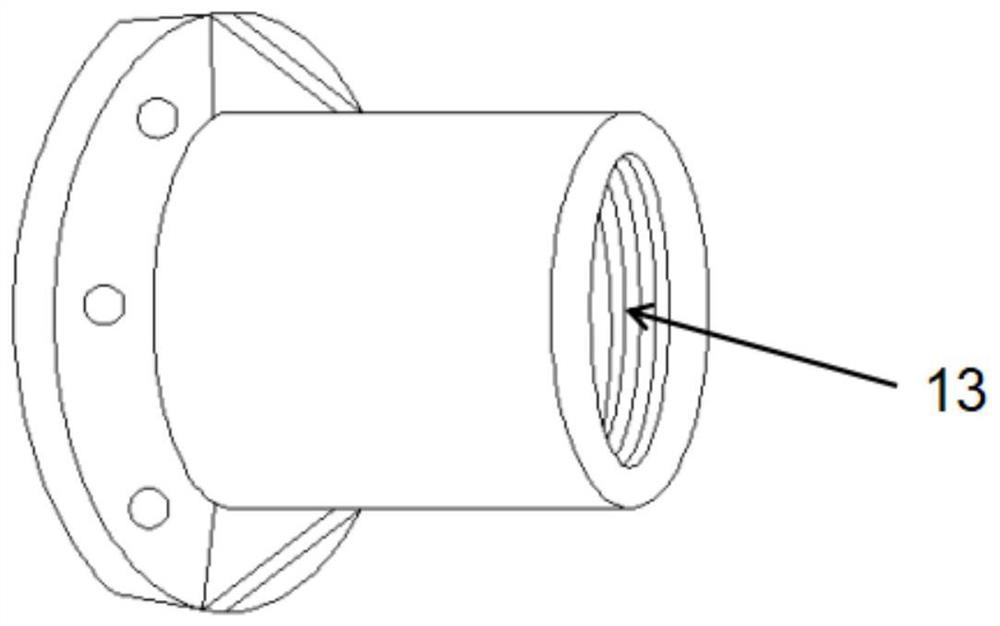

[0062] Please refer to Image 6 , on the basis of the first embodiment, the anti-skid structure 13 with the same pit pattern on the inner surface of the outer casing is added to the bottom surface of the outer surface of the outer casing. reliability. The depressions are in a textured pattern. The texture pattern is in a wave shape, a spiral shape, a concentric circle, a zigzag shape, a grid shape, etc., and the convex shape is a zigzag shape, and the shape of the zigzag includes at least one of a triangle, a rectangle, a trapezoid, and a semicircle.

Embodiment 3

[0064] Please refer to Figure 7 , The difference from the first embodiment is that the anti-skid structure is provided with many sharp protrusions on the inner surface of the shell, and the protrusions are in texture patterns. The texture pattern is in the shape of a grid, the shape of the protrusions is in the shape of zigzag, and the shape of the zigzag includes at least one of a triangle, a rectangle, a trapezoid, and a semicircle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com