Drill rod detection machine

A technology of drilling machine and frame, which is applied in the field of foundation soil survey, foundation structure test, construction, etc., which can solve the problem of affecting the accuracy of falling hammer hammering, heavy data recording workload, false reporting of hammering numbers or False reporting and other problems, to achieve the effect of simple structure, time-consuming and labor-intensive solutions, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

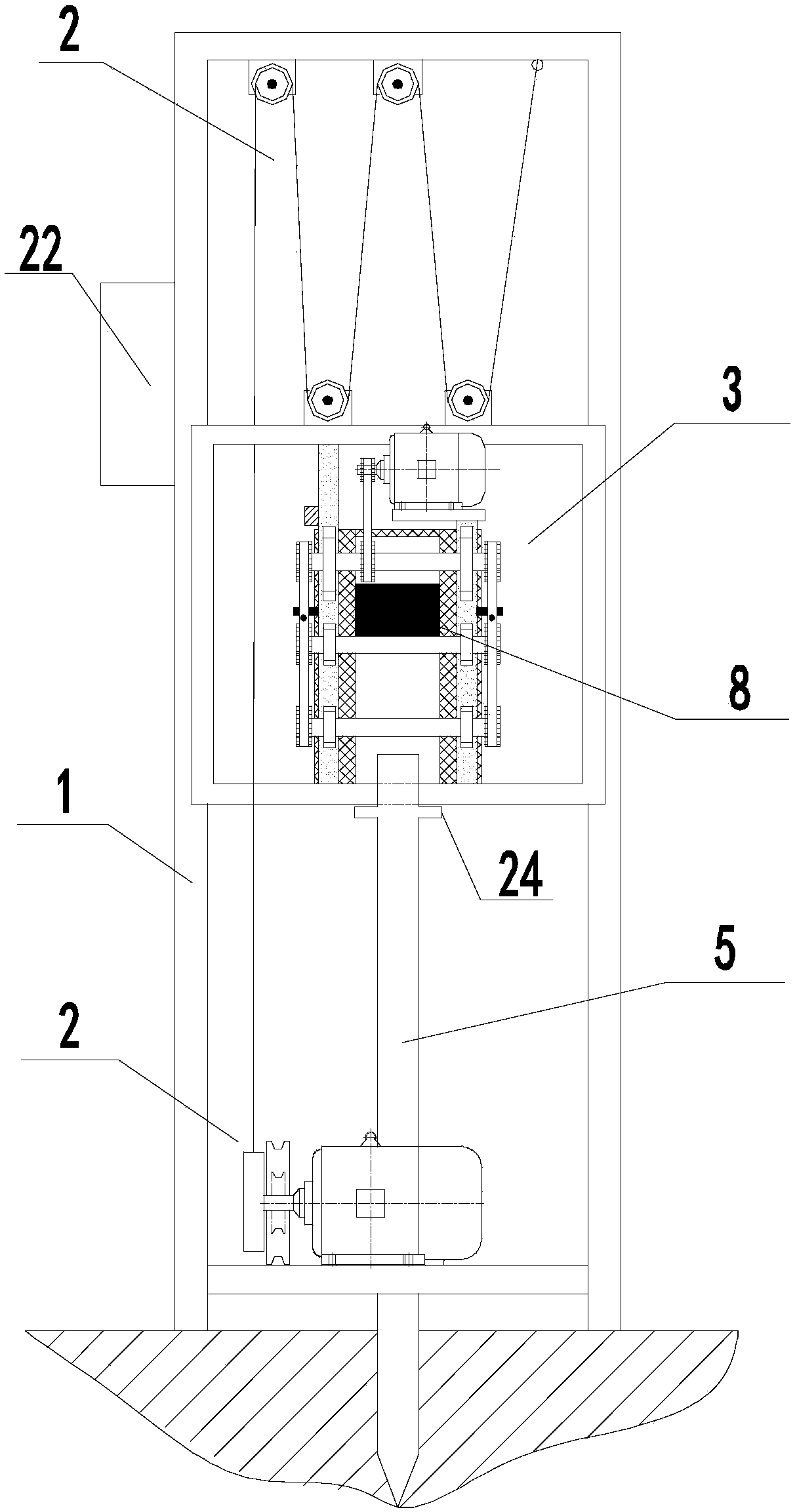

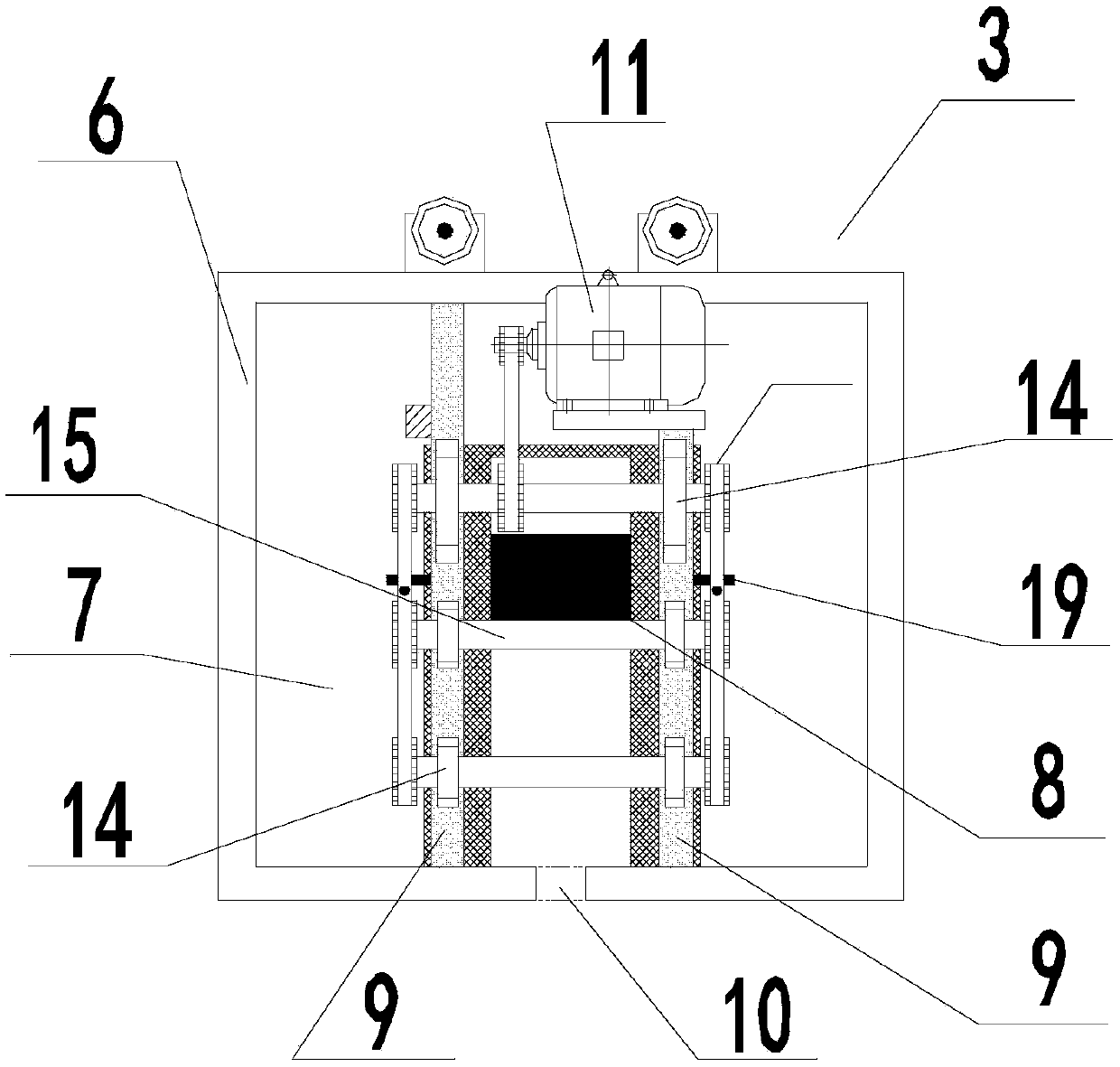

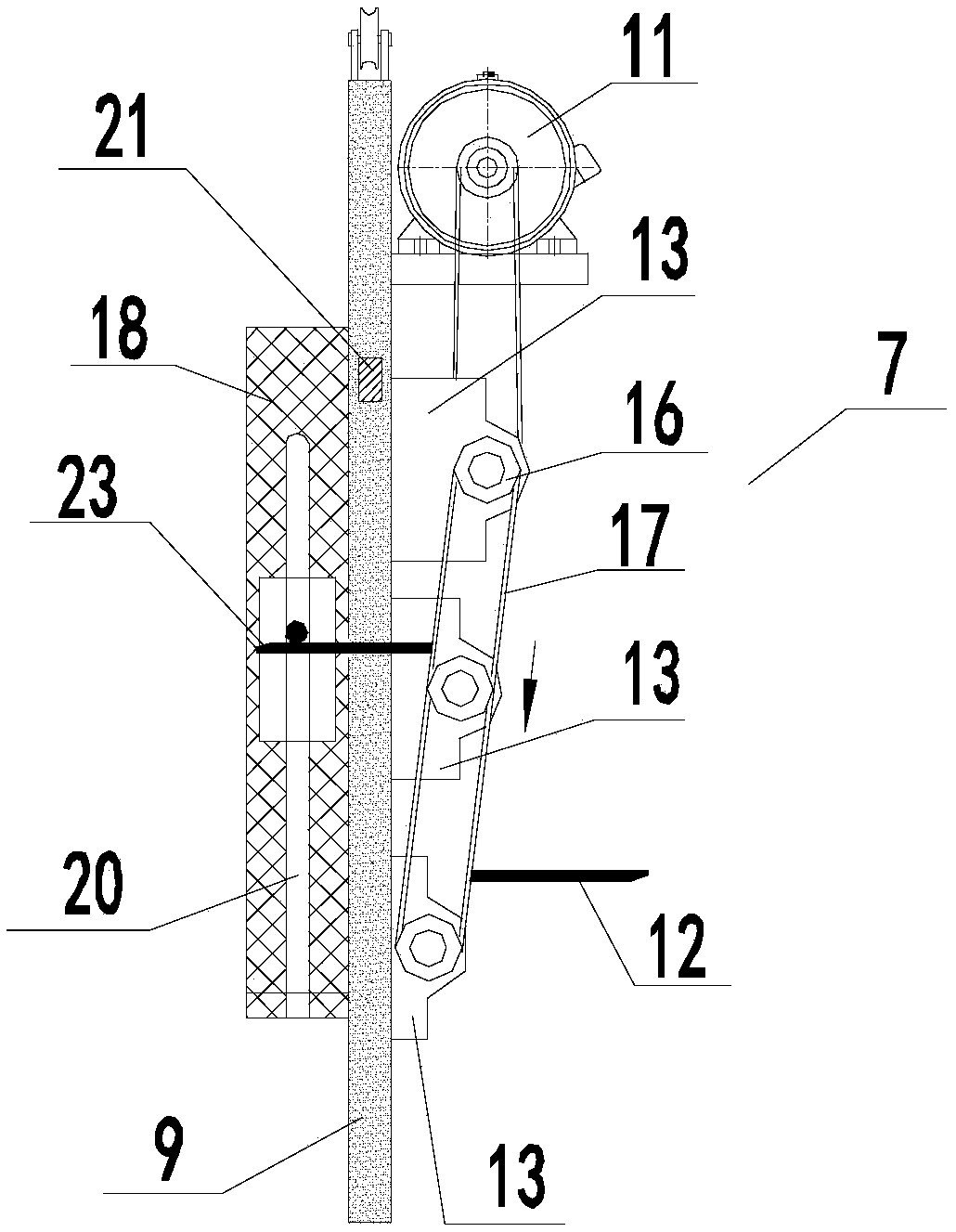

[0017] Such as Figure 1-3 As shown, a drilling machine includes a frame 1, a main transmission mechanism 2 arranged on the frame 1, a drop hammer mechanism 3, a counting mechanism and a probe rod 5, and a guide chute 4 is arranged on the inside of the frame 1 , the main transmission mechanism 2 drives the falling weight mechanism 3 to slide up and down in the guide chute 4, and the counting mechanism records the number of times the falling weight of the falling weight mechanism 3 hits the probe rod 5.

[0018] The falling weight mechanism 3 includes a sliding frame 6, an auxiliary transmission mechanism 7 and a dropping weight 8. The two sides of the sliding frame 6 slide up and down in the guide chute 4, and the two sides of the middle part of the sliding frame 6 are respectively Two fixing plates 9 connecting the upper and lower sides of the sliding frame 6 are fixed, and a probe rod hole 10 is provided in the middle of the lower part of the sliding frame 6, and a probe rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com