An assembled connection node between a plug-in buckle beam and a column

A connection node and assembly technology, applied in the direction of construction, building structure, etc., can solve the problems of increased fire, large manpower and material resources, slow construction speed of steel structures, etc., and achieve the effect of avoiding axial displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

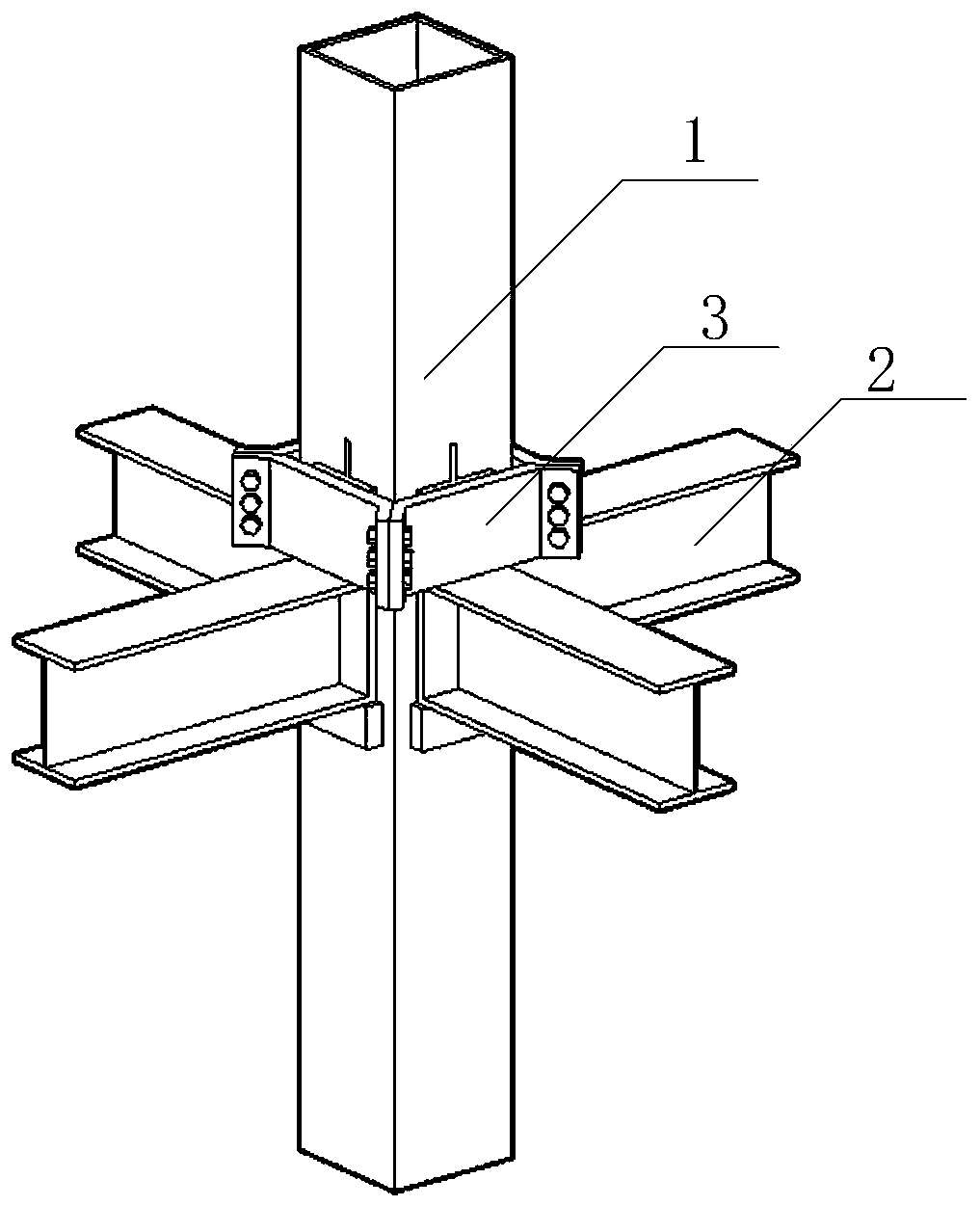

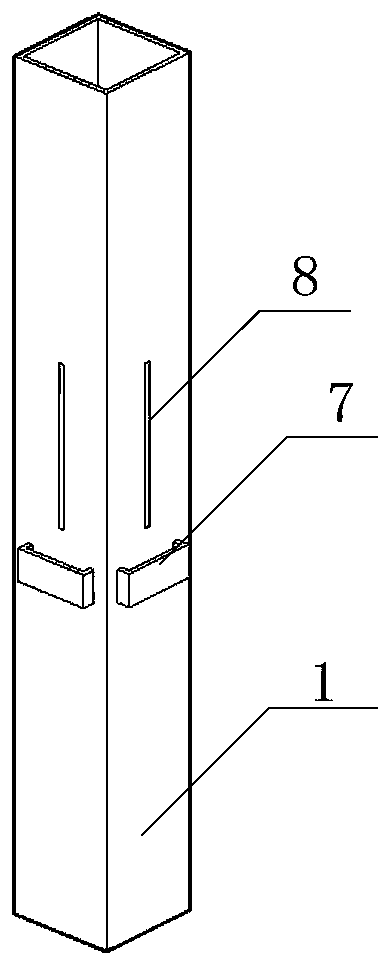

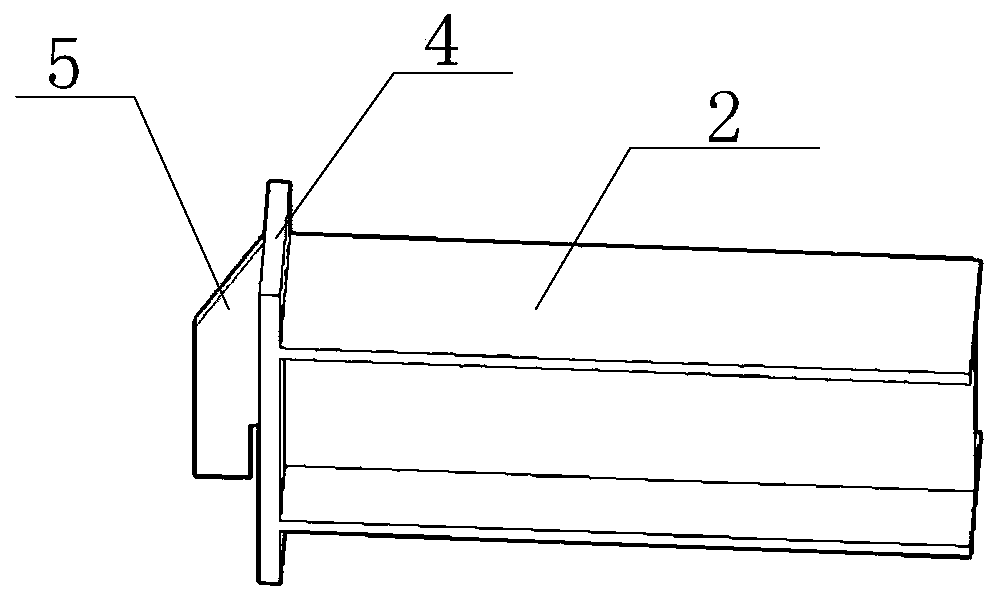

[0018] refer to Figure 1 to Figure 4 , the assembled connection node of the plug-in buckle beam and column according to the present invention includes a steel pipe column 1, a number of embedded steel plates 5 and a number of steel beams 2, wherein each steel beam 2 is provided with a fixing plate 4 at the end, and the steel pipe The side of the column 1 is provided with a number of slots 8, wherein a slot 8 corresponds to an embedded steel plate 5 and a fixed plate 4, and the upper side of each embedded steel plate 5 is fixedly connected with the corresponding fixed plate 4, and each embedded steel plate 5 There is a gap between the lower side of the steel beam and the corresponding fixed plate 4, wherein each embedded steel plate 5 is inserted into the corresponding slot 8, and the side wall of the steel pipe column 1 is inserted into the gap, and the top of each st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com