A Ductile Coupling Beam Swing Steel Frame System

A steel frame and connecting beam technology, applied in the direction of building types, buildings, building components, etc., can solve the problems of serious component damage, difficult control, and difficult repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

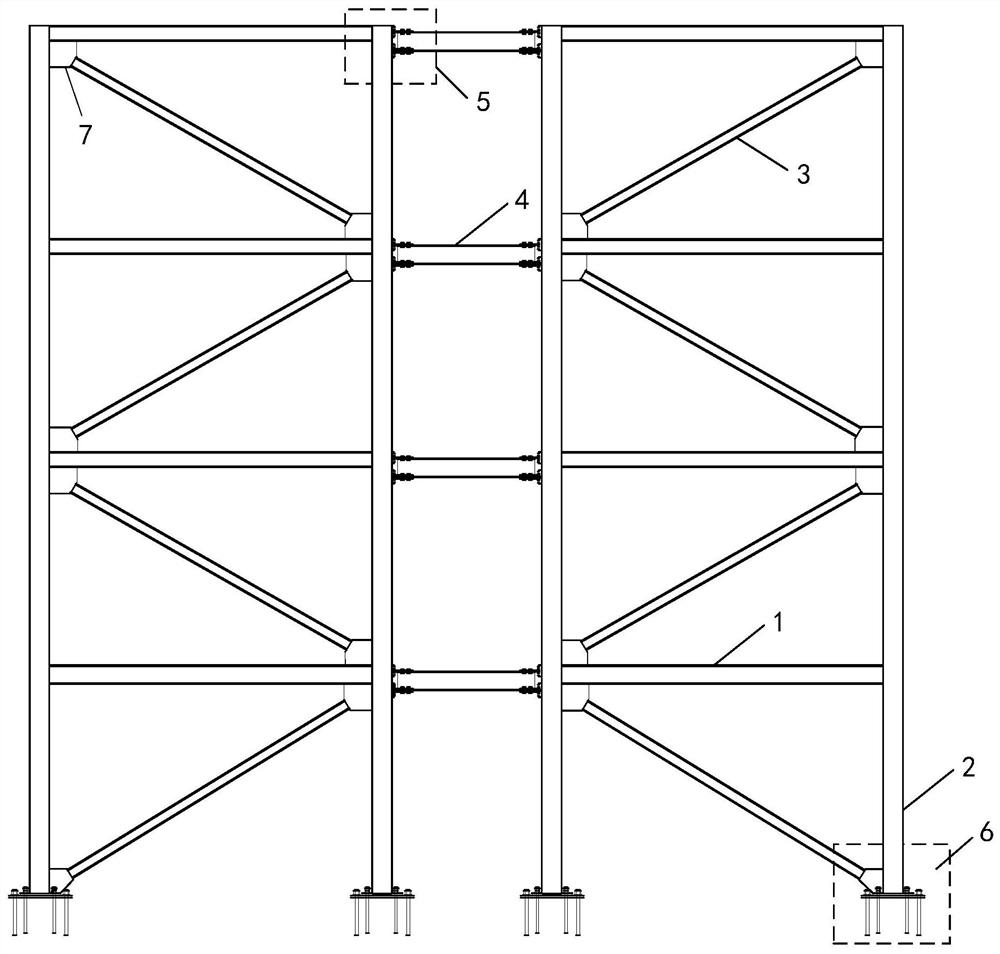

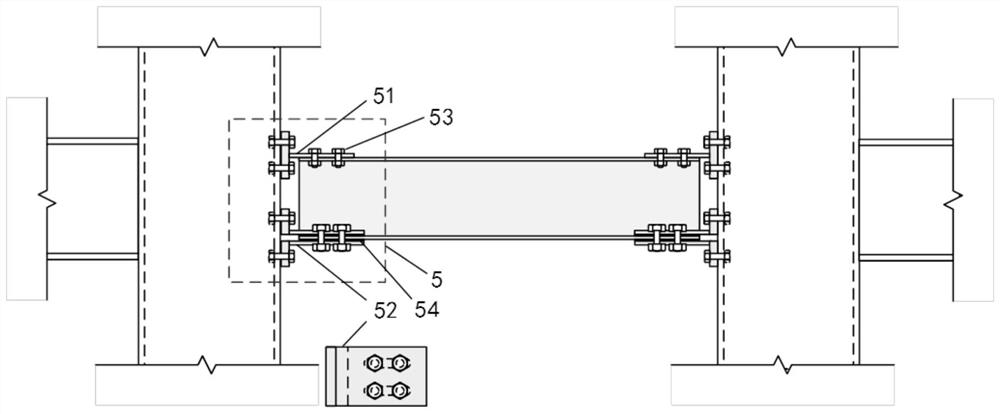

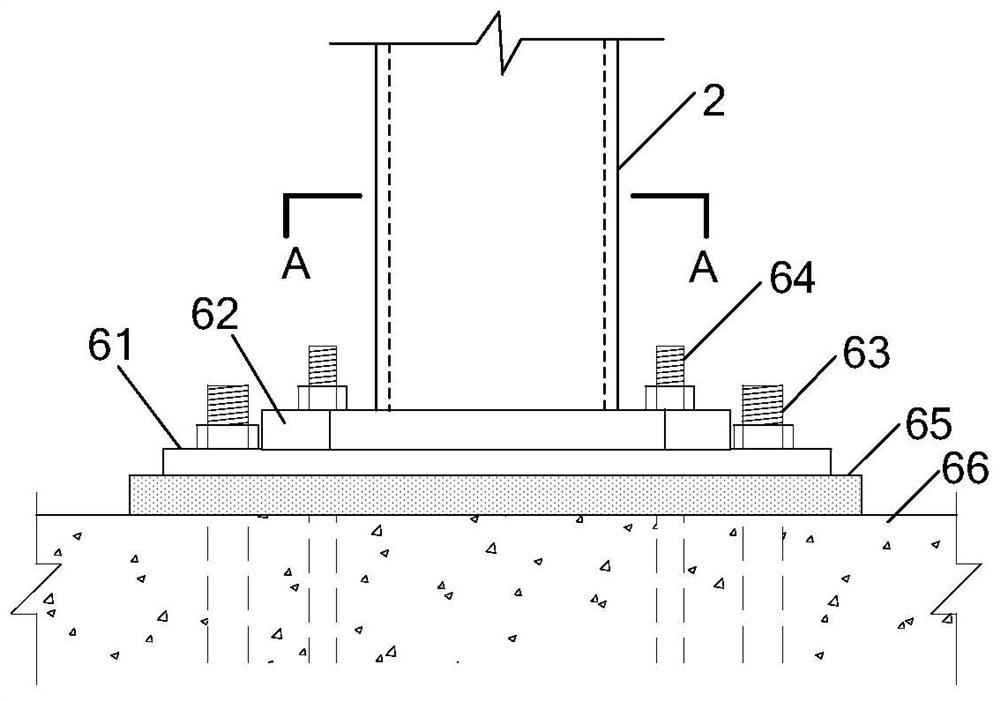

[0026] Embodiment 1: As shown in the figure, the present invention is a swinging steel frame structure system with ductile coupling beams, which mainly consists of frame beams 1, frame columns 2, steel supports 3, replaceable coupling beams 4, and energy-dissipating beam-column nodes 5 And swing type column foot 6 forms. Frame beam 1, frame column 2 and steel support 3 form a steel support frame, and steel support 3 is installed at the inner diagonal position of the steel support frame on both sides of each floor, and the steel support frames on the left and right sides are connected by replaceable connecting beam 4 , the replaceable connecting beam 4 is connected to the frame column 2 through the energy-dissipating beam-column node 5, and the bottom of the frame column 2 adopts a swing-type column foot 6.

[0027] The frame beam 1 is in the form of a steel member such as an I-shaped cross section or a square steel pipe cross section.

[0028] The frame column 2 is in the cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com