Fabricated shear resisting unit and wall fabricated through shear resisting unit

A prefabricated, wall technology, applied in the direction of walls, building components, insulation, etc., can solve problems such as backwardness, achieve good shear resistance and load-bearing capacity, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

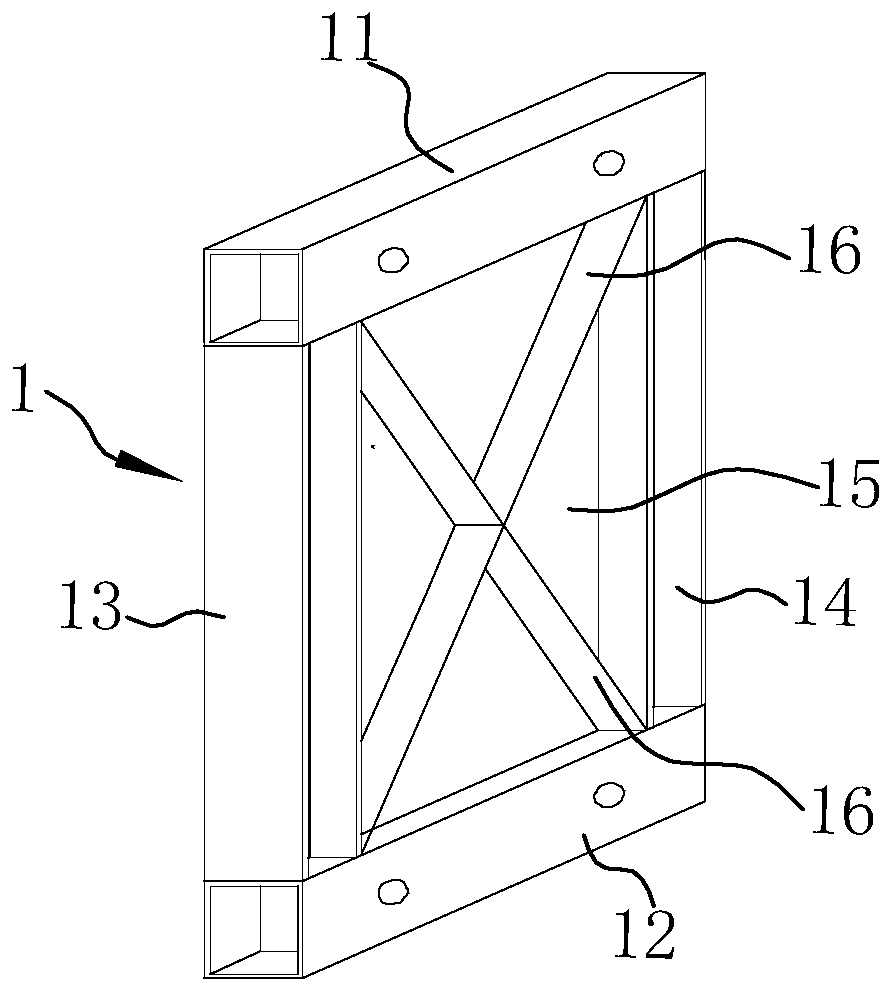

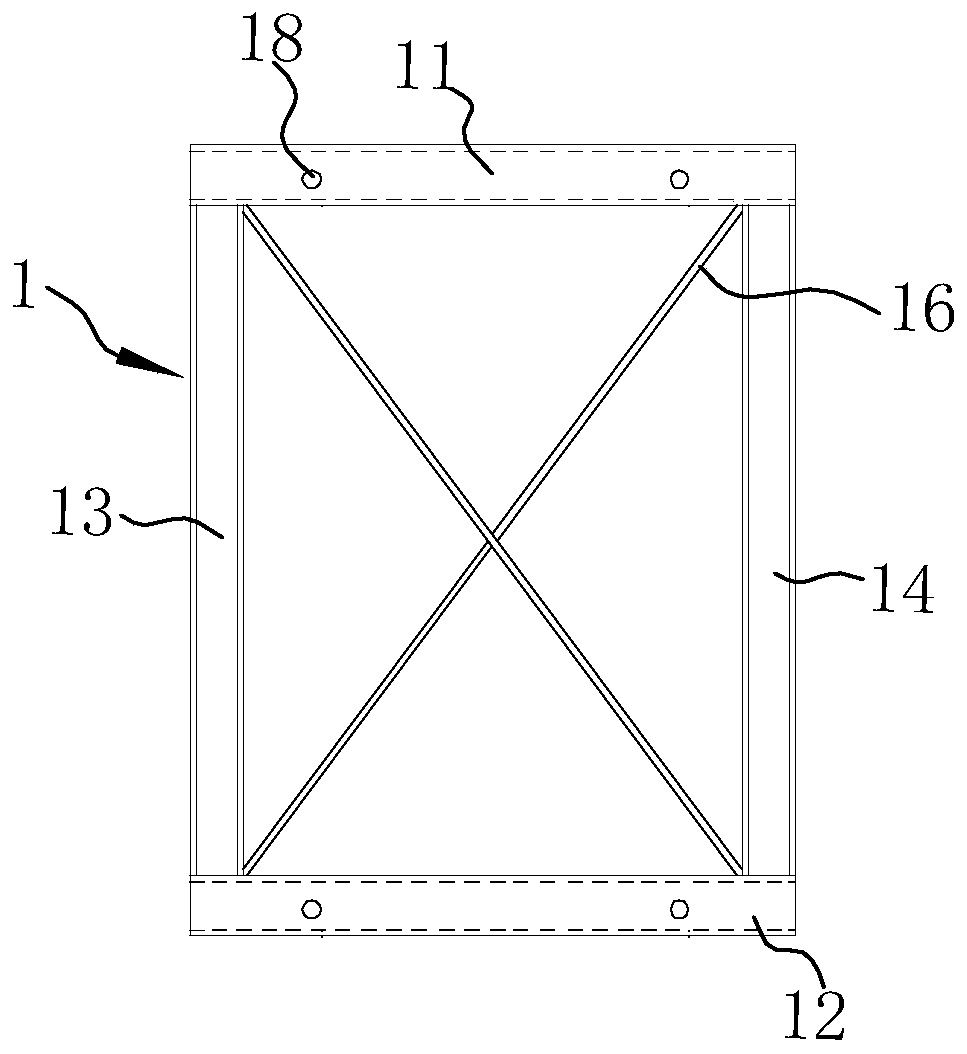

[0051] An assembled shear unit, which is divided into type I shear unit 1 and type II shear unit 2, wherein such as Figure 1~3 As shown, the type I shear unit includes

[0052] The first frame is fixedly connected by the first upper frame member 11, the first lower frame member 12, the first left frame member 13, and the first right frame member 14 to form an internal hollow first frame;

[0053] The first support plate 15 is arranged at the hollowed out place inside the first frame;

[0054] Two stiffeners 16 arranged in a cross on the diagonal of the first frame, and the two stiffeners 16 are welded to the back of the first support plate 15;

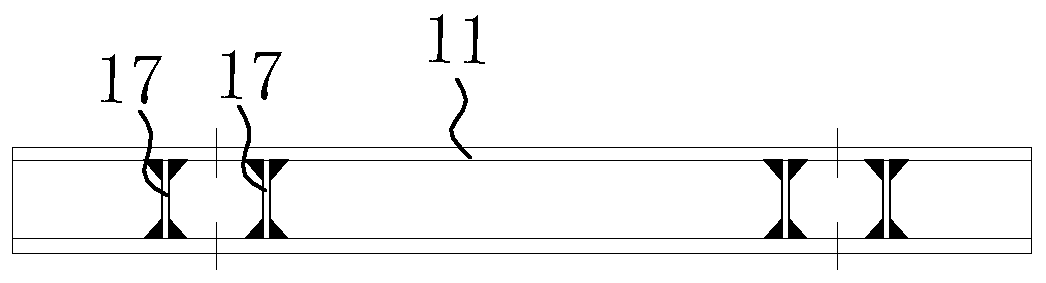

[0055] In order to realize the assembly of the I-type shear unit 1 and to increase the strength during assembly, the first upper frame member 11 is a hollow rectangular steel body, and the front and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com