Aluminium alloy template used for variable cross-section of wall column and design method of aluminium alloy template

A technology of aluminum alloy formwork and variable cross-section, which is applied in the fields of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem of high processing cost and duplication of spare formwork Problems such as low utilization rate achieve the effect of reducing construction cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

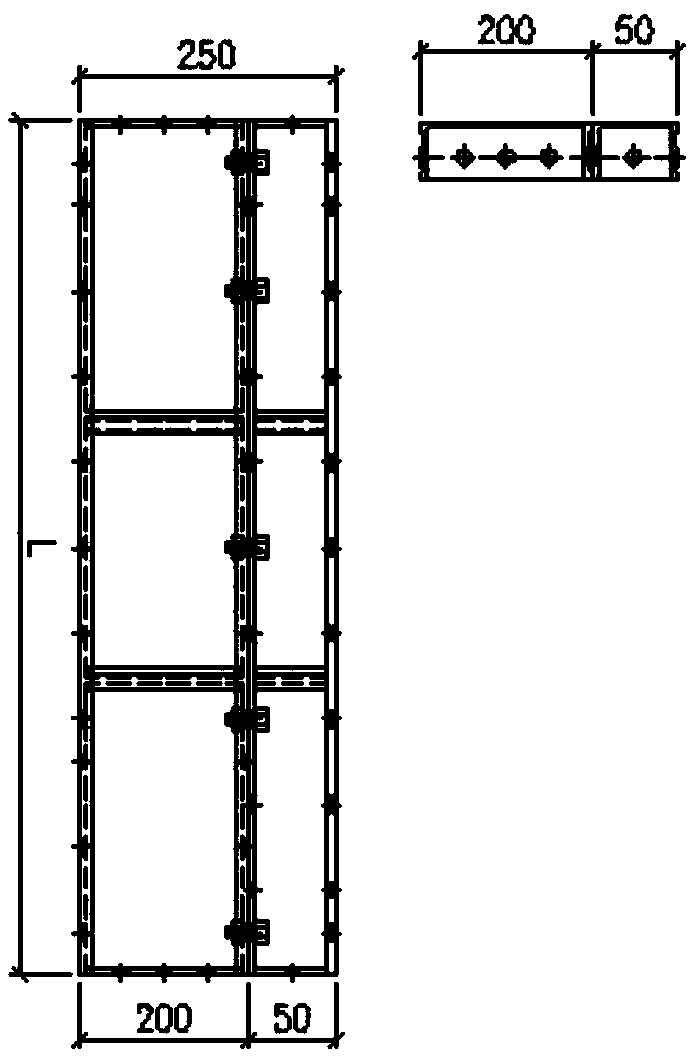

[0033] Embodiment 1: refer to figure 1 and 2 ;

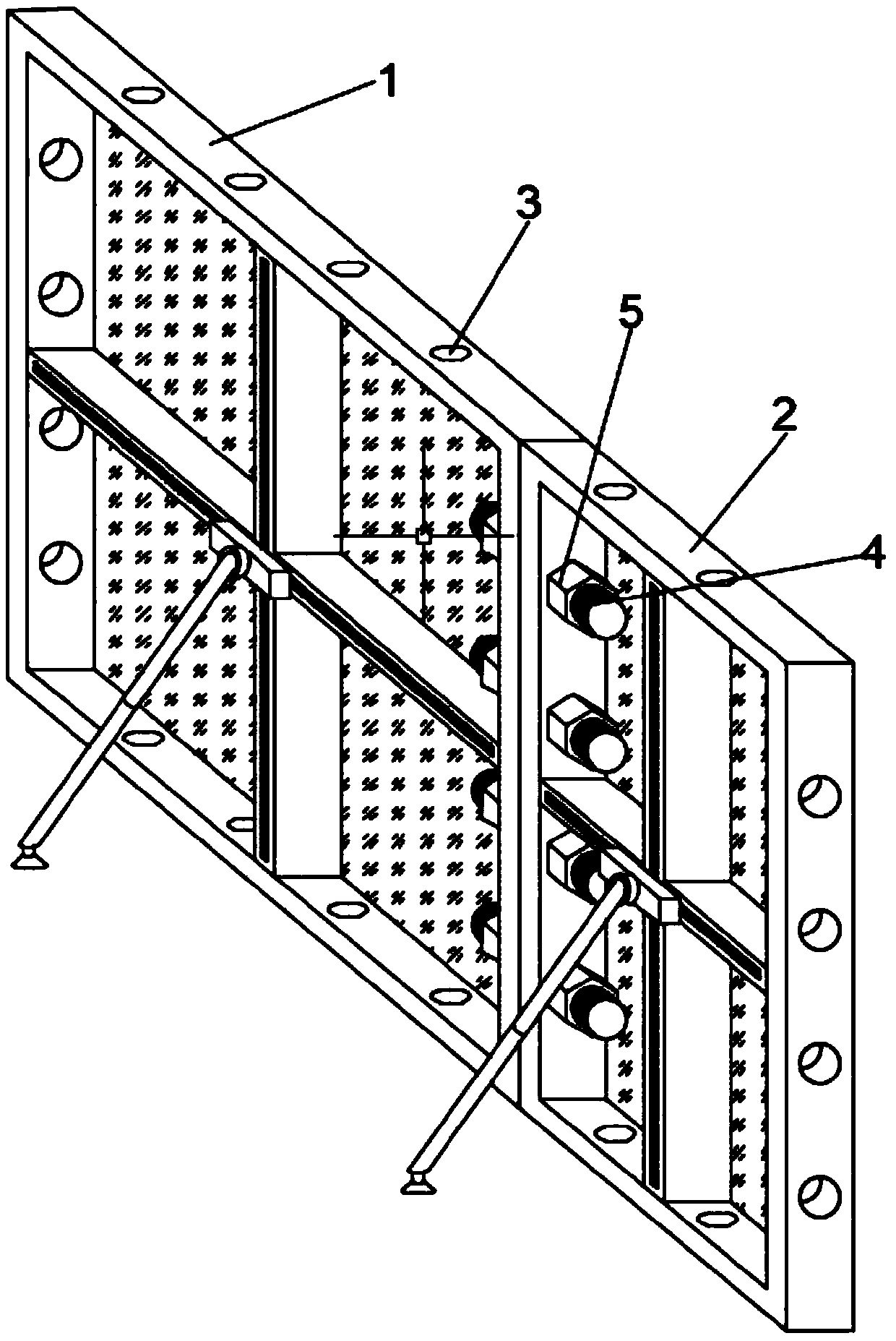

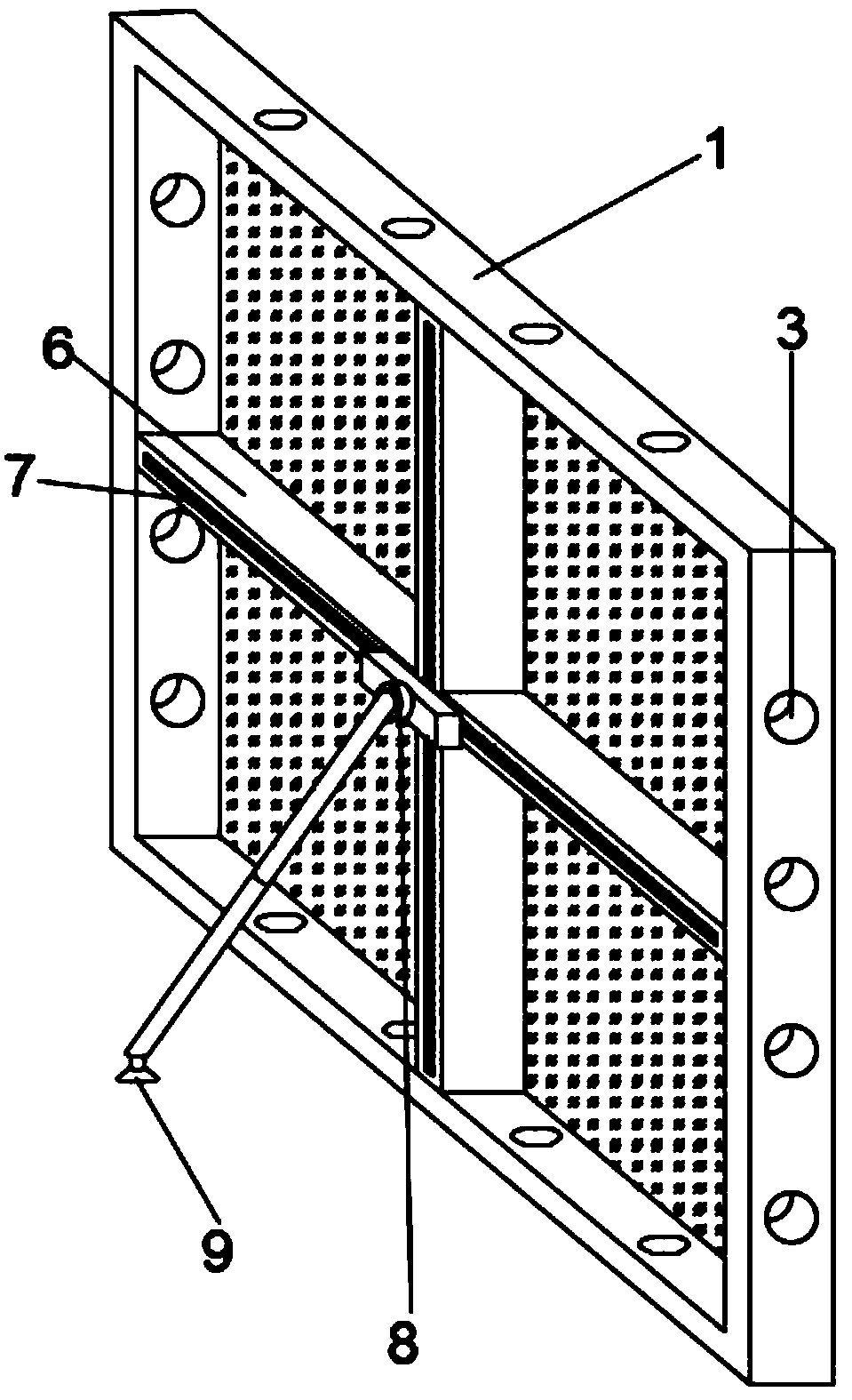

[0034] An aluminum alloy formwork for a variable section of a wall column, comprising a wide-side aluminum alloy formwork 1 and a narrow-side aluminum alloy formwork 2, the wide-side aluminum alloy formwork 1 and the narrow-side aluminum alloy formwork 2 are provided with formwork connecting pin holes 3, and the formwork The connecting pin hole 3 is penetrated by bolts 4, and the bolts 4 are threaded to connect the nuts 5. The wide-side aluminum alloy formwork 1 and the narrow-side aluminum alloy formwork 2 are spliced by bolts 4; the wide-side aluminum alloy formwork 1 and the narrow-side aluminum alloy formwork 2 also include There is a cross reinforcement frame 6, a diagonal bracing device 8 and a friction support device 9, and the back of the wide-side aluminum alloy formwork 1 and the narrow-side aluminum alloy formwork 2 is fixedly connected with a cross reinforcement frame 6, and the outer surface of the cross reinforc...

Embodiment 2

[0036] Embodiment 2: The difference based on Embodiment 1 is;

[0037] The cross reinforcement frame 6 also includes a ball groove 15, a sliding opening 16 and a draw-in groove 17, the front end of the middle part of the cross reinforcement frame 6 is provided with a ball groove 15, the inner end of the cross reinforcement frame 6 is provided with a sliding opening 16, the bottom surface of the cross reinforcement frame 6, etc. Multiple sets of card slots 17 are arranged.

[0038] The diagonal support device 8 includes a connecting rod 10, a support seat 11, a rotating head 12, a splicable support rod 13 and a rolling ball 18. The rolling ball 18 is slidably connected with the ball groove 15. The middle part of the rolling ball 18 is provided with a through opening 19, which can be spliced. The lower end of the support rod 13 is movably connected with a friction support device 9, the upper end of the splicable support rod 13 is rotationally connected with the outer end of the ...

Embodiment 3

[0042] Embodiment 3: the difference based on the basis of embodiment 1 or embodiment 2 is;

[0043] A design method for an aluminum alloy formwork when a wall column has a variable section, the method uses the aluminum alloy formwork for a wall column with a variable section according to claims 1-4, and the method includes:

[0044] S1, making wide-side aluminum alloy formwork 1 and narrow-side aluminum alloy formwork 2 with different width specifications and standards, and transporting wide-side aluminum alloy formwork 1 and narrow-side aluminum alloy formwork 2 to the construction site for wall column section transformation;

[0045] S2. Comparing the construction drawings of the wall column structure, determine the width dimension X+Y before the wall column section transformation layer transformation and the width dimension X after the wall column section transformation layer transformation, and then calculate the wall column section transformation layer transformation befor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com