Winding structure wall pipe with positioning structure and production process thereof

A technology for positioning structure and structural wall pipe, applied in the direction of pipe, rigid pipe, pipeline protection, etc., can solve the problems of long construction time, damage, affecting normal use, etc., to improve construction efficiency, read and write information accurately, and ensure qualified sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

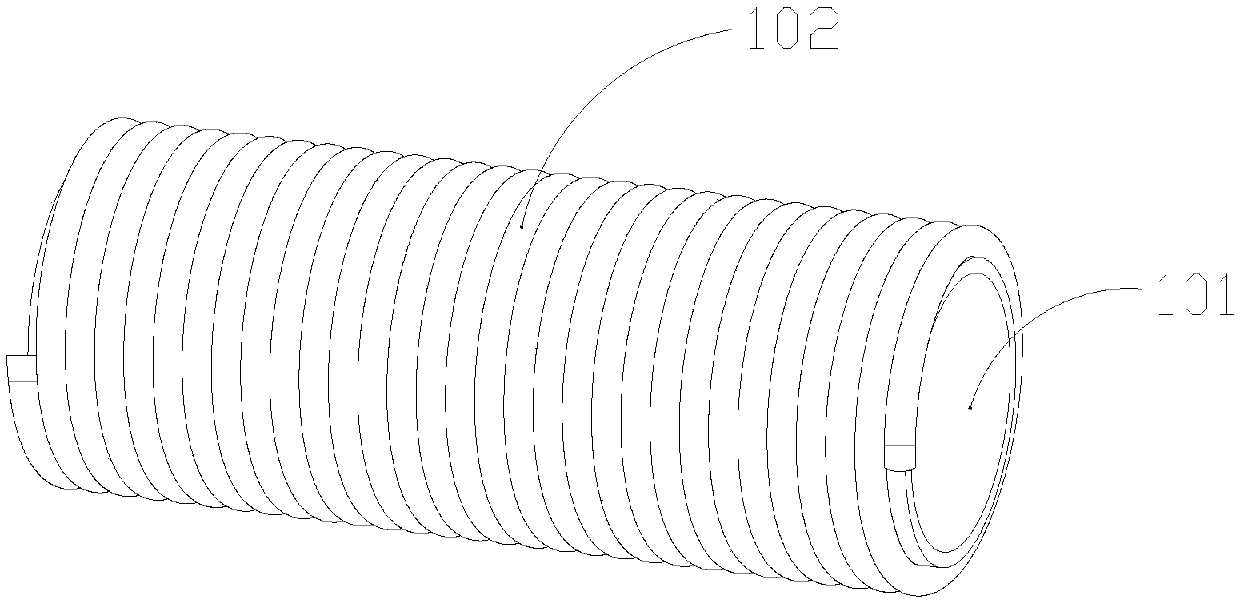

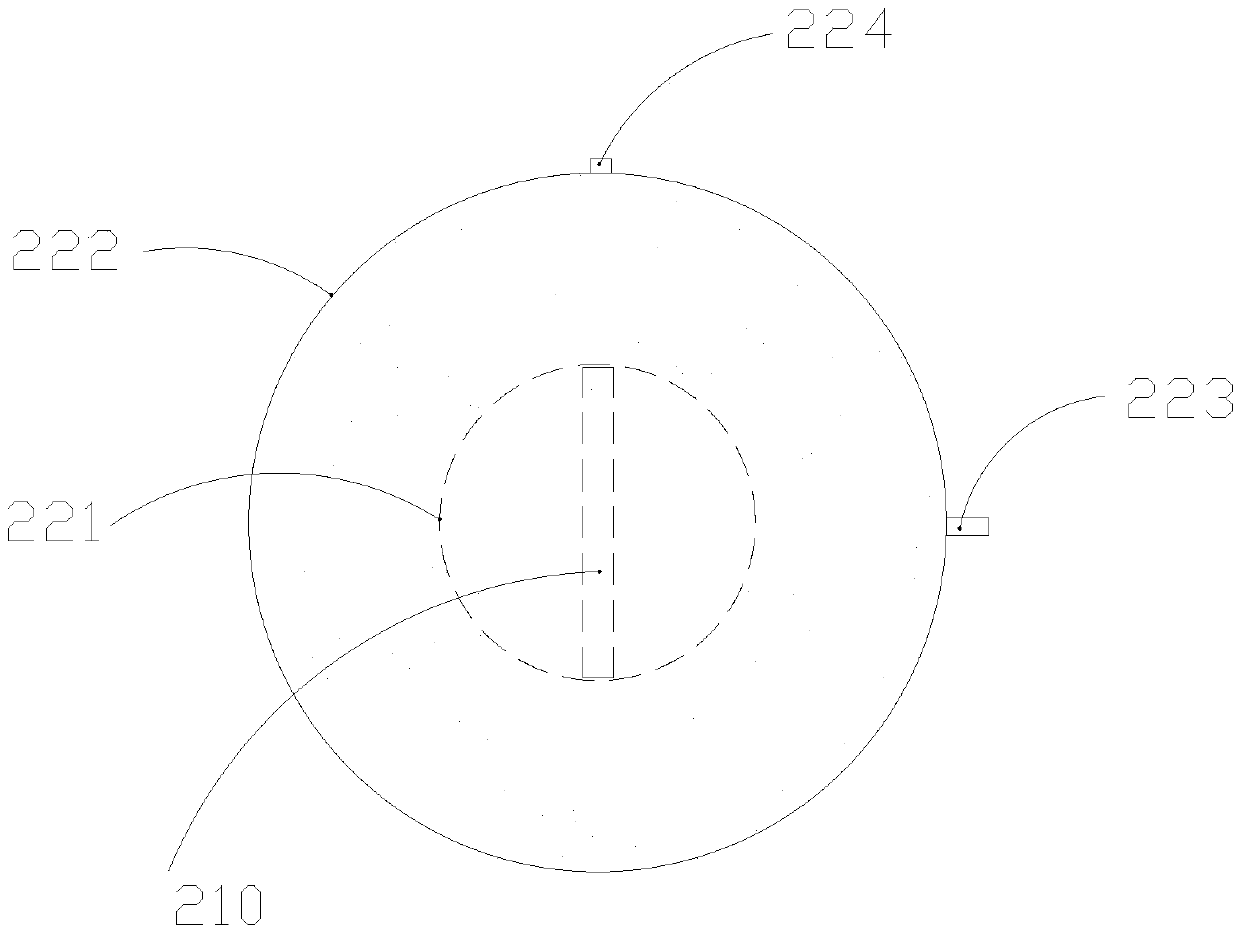

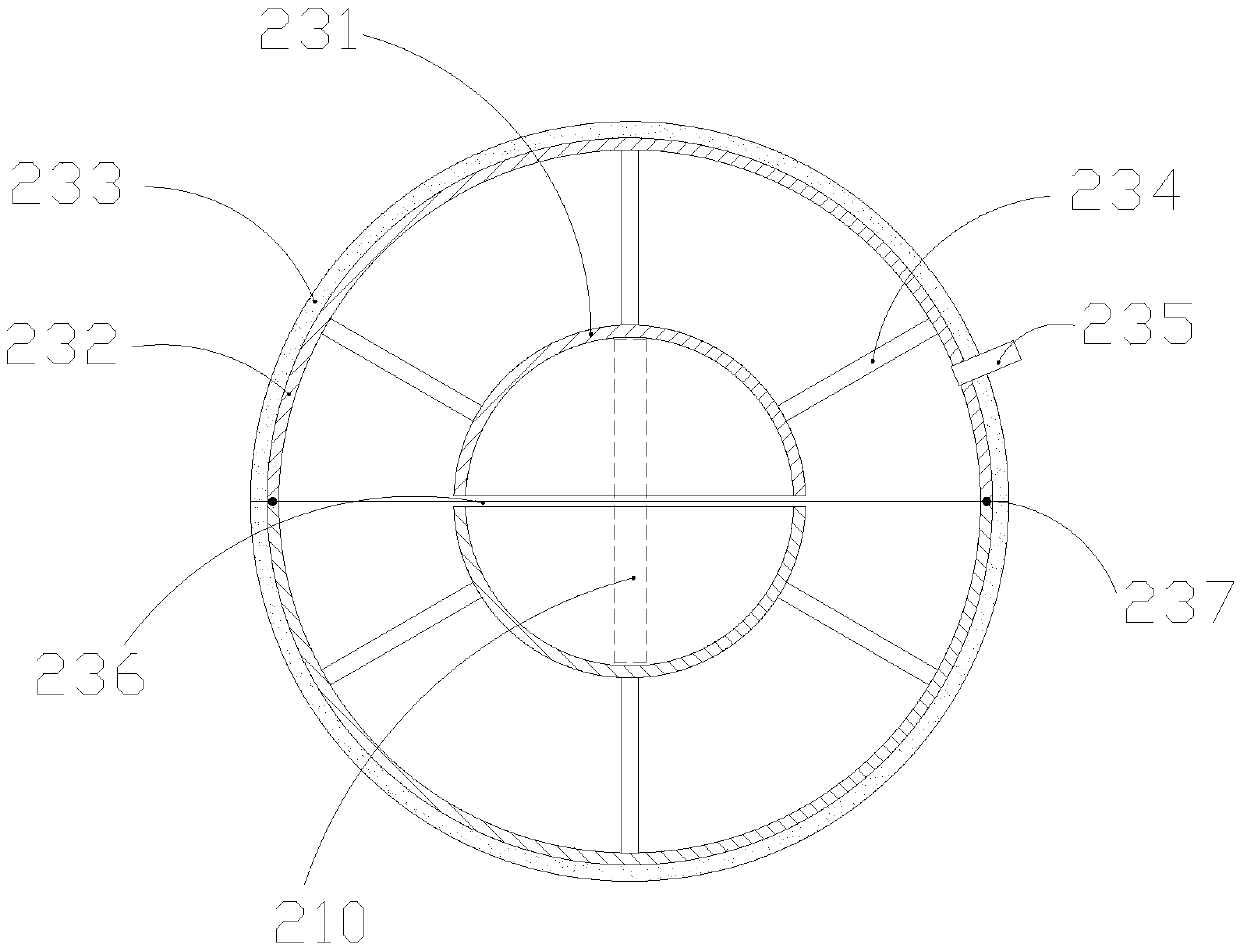

[0043] Such as figure 1 and figure 2 As shown, a winding structure wall pipe with a positioning structure includes a main body formed by connecting one or more branch pipe bodies 101 and a rib pipe 102 spirally and equidistantly wound from one end of the outer wall of the branch pipe body 101 to the other end. The two ends of the rib tube 102 are closed or narrowed, and one end of the inner cavity of the rib tube 102 is filled with a positioning structure for locating the geographical position of the branch body 101. The positioning structure includes an electronic marker 210, and the electronic marker The outer seal of 210 is wrapped with a heat insulation layer, and the outer surface of the heat insulation layer is an elastic structure that can be squeezed by the inner cavity of the finned tube 102 to fix its relative position with the finned tube 102 .

[0044] For the structure of the heat insulation layer, a liquid capsule is used, and the thermal conductivity of the li...

Embodiment 2

[0063] Such as figure 1 and figure 2 As shown, a winding structure wall pipe with a positioning structure includes a main body formed by connecting one or more branch pipe bodies 101 and a rib pipe 102 spirally and equidistantly wound from one end of the outer wall of the branch pipe body 101 to the other end. The two ends of the rib tube 102 are closed or narrowed, and one end of the inner cavity of the rib tube 102 is filled with a positioning structure for locating the geographical position of the branch body 101. The positioning structure includes an electronic marker 210, and the electronic marker The outer seal of 210 is wrapped with a heat insulation layer, and the outer surface of the heat insulation layer is an elastic structure that can be squeezed by the inner cavity of the finned tube 102 to fix its relative position with the finned tube 102 .

[0064] For the structure of the heat insulation layer, a gaseous bag is used, and the thermal conductivity of the gas i...

Embodiment 3

[0083] Based on Embodiment 1 or Embodiment 2, the thermal insulation bag is in a spherical or cylindrical structure after being expanded. It is preferably a cylindrical structure, the axial direction of which is the same as the axial direction of the rib tube 102, and can have a larger contact area with the rib tube 102. Prevent the positioning structure from moving.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com