Multi-shift planning scheduling method based on improved variable neighborhood genetic algorithm

A genetic algorithm and multi-shift technology, applied in the field of intelligent manufacturing, can solve the problems of low scheduling flexibility, gaps in scheduling results, and low labor efficiency, so as to expand the search range, ensure full utilization, and improve convergence speed The effect on the quality of the settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

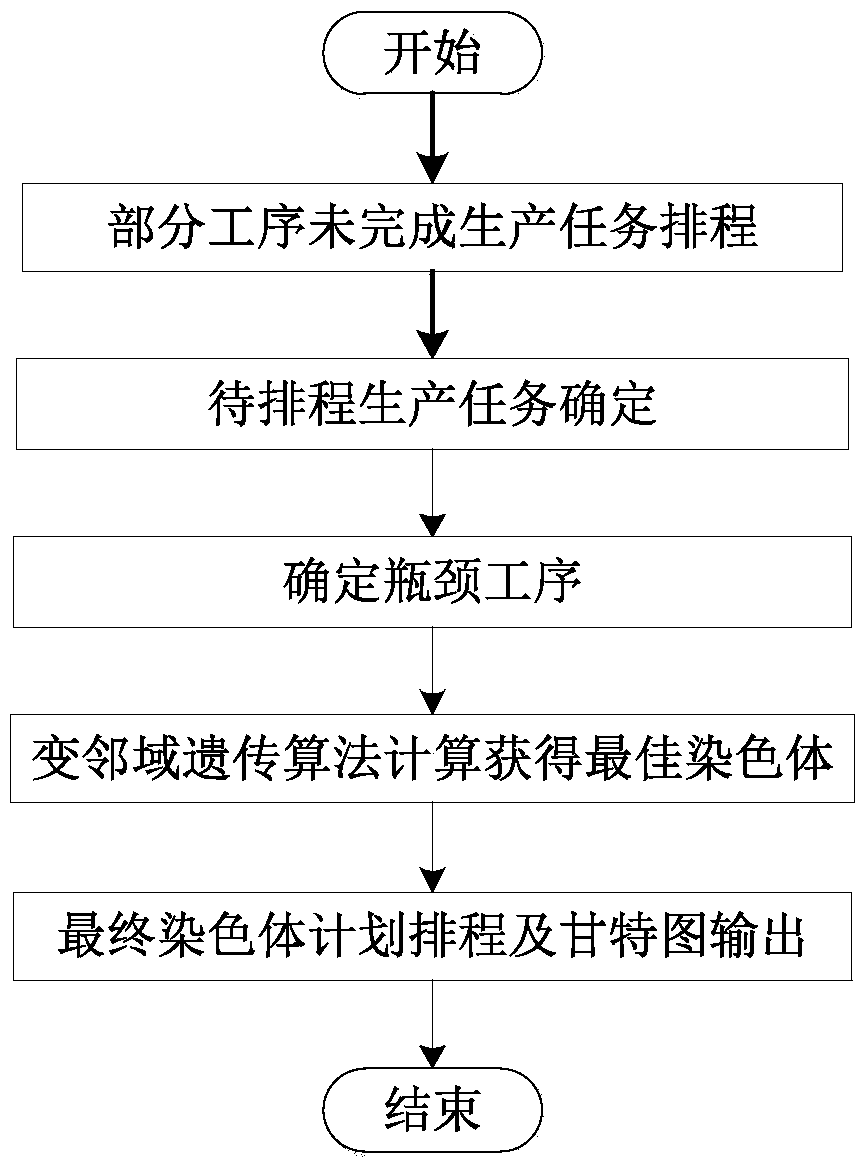

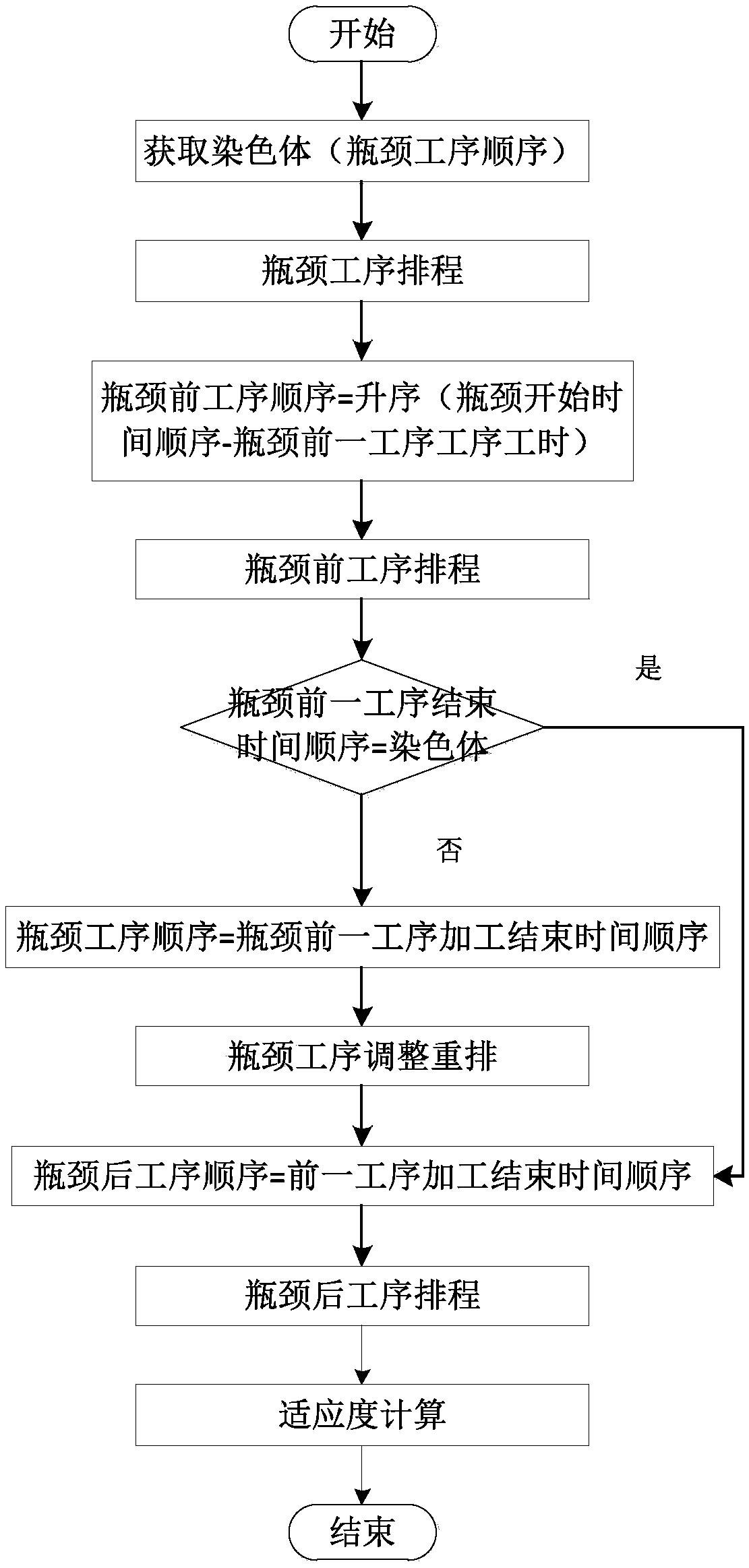

[0029] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

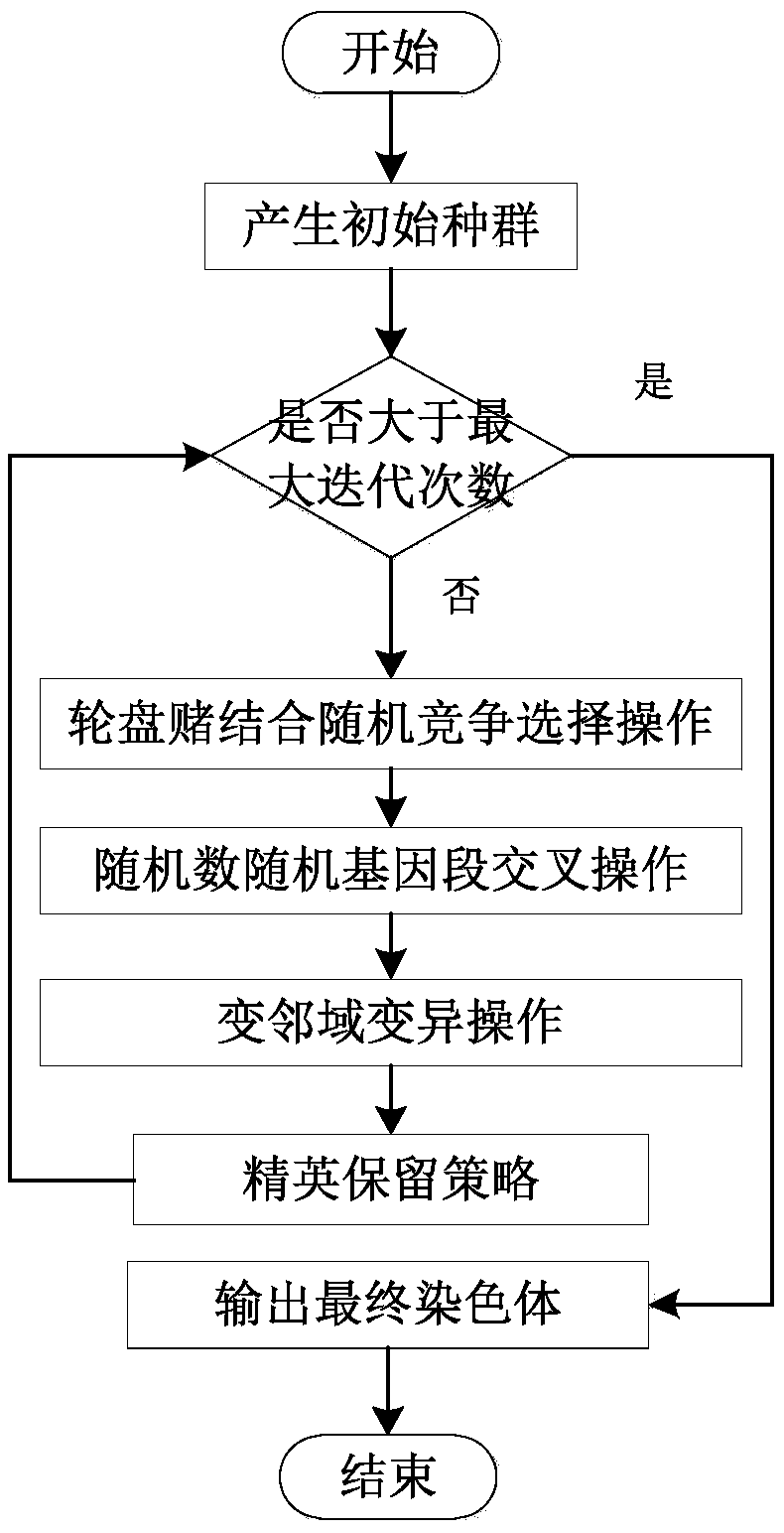

[0030] In this scheduling method, the variable neighborhood genetic algorithm is used, and the selection operation of the genetic algorithm adopts the combination of roulette selection and random competitive selection method, which avoids the shortcomings of too much randomness in roulette selection, and the crossover operation adopts random number Random gene segment crossover, expanding the search range, combining the mutation operation with the variable neighborhood algorithm, taking the chromosome with the best fitness in the neighborhood of the mutated chromosome as the final mutated chromosome, after the selection, crossover and mutation operations are completed, use the last The individual with the best iterative fitness replaces the individual with the worst iterative fitness, avoiding the prematurity of the variable neighb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com