Inverse Scott transformer

A Scott transformer, low-voltage coil technology, applied in the direction of transformers, variable transformers, transformer/inductor components, etc., can solve problems such as resistance unbalance, and achieve the effect of resistance balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

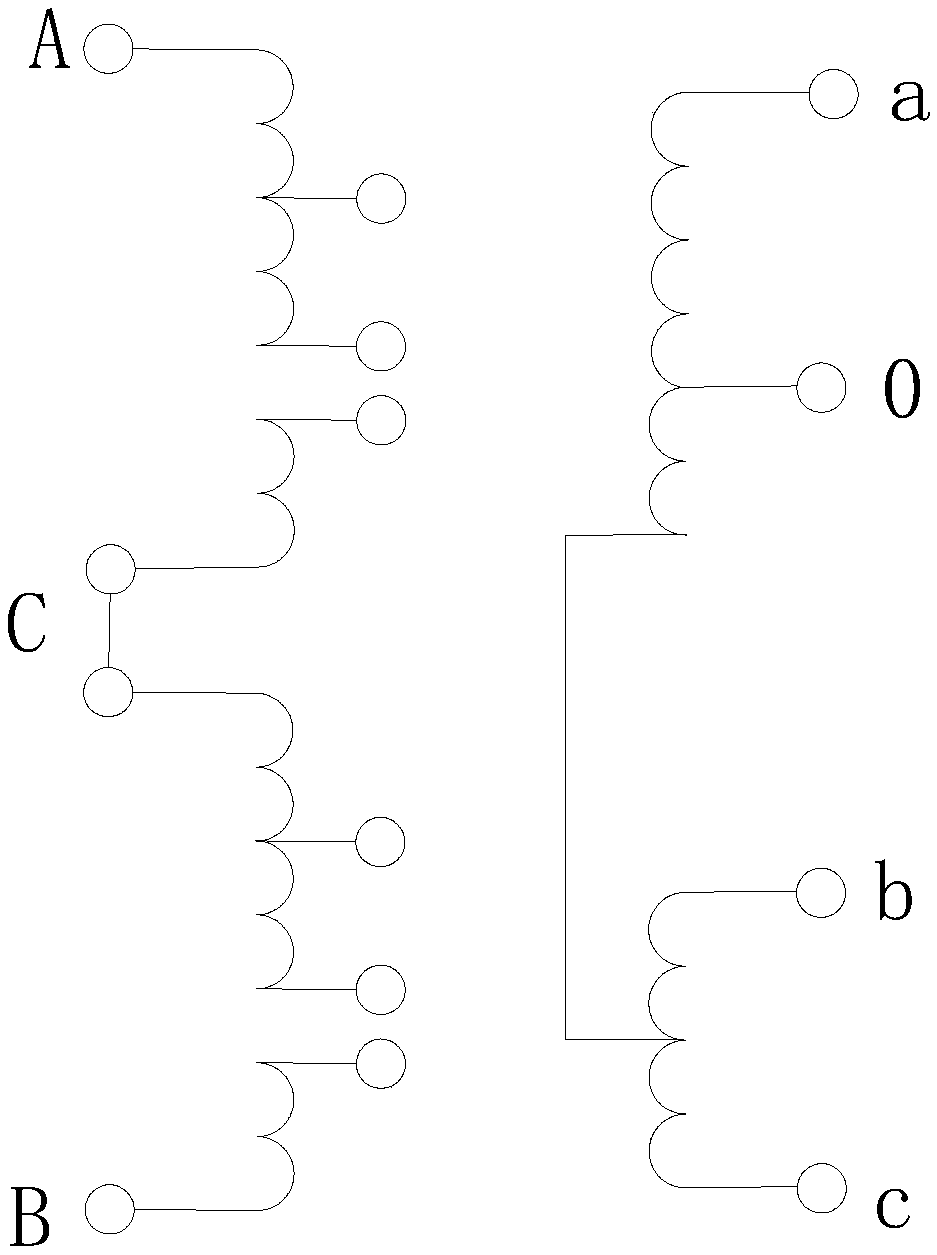

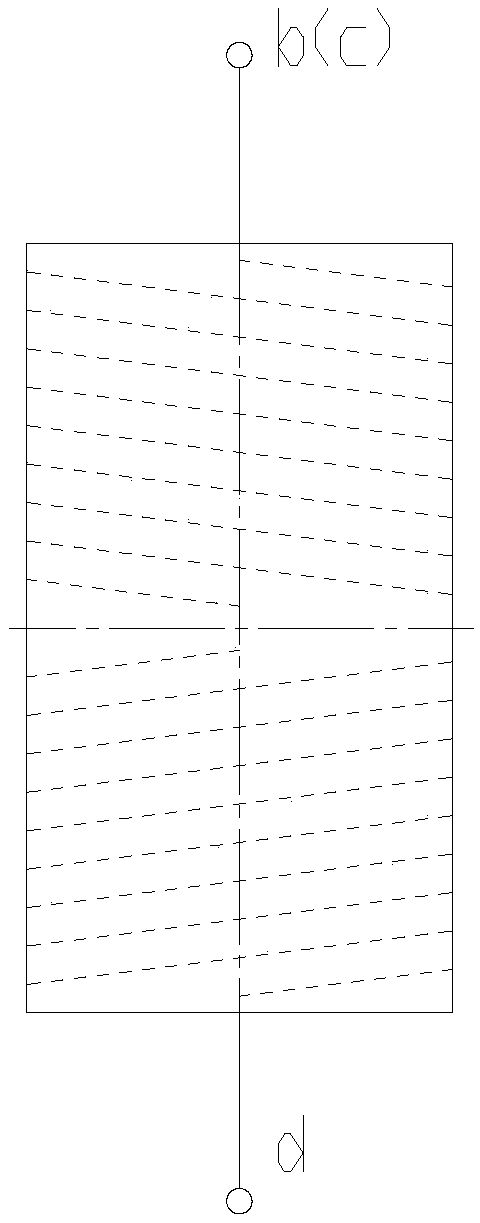

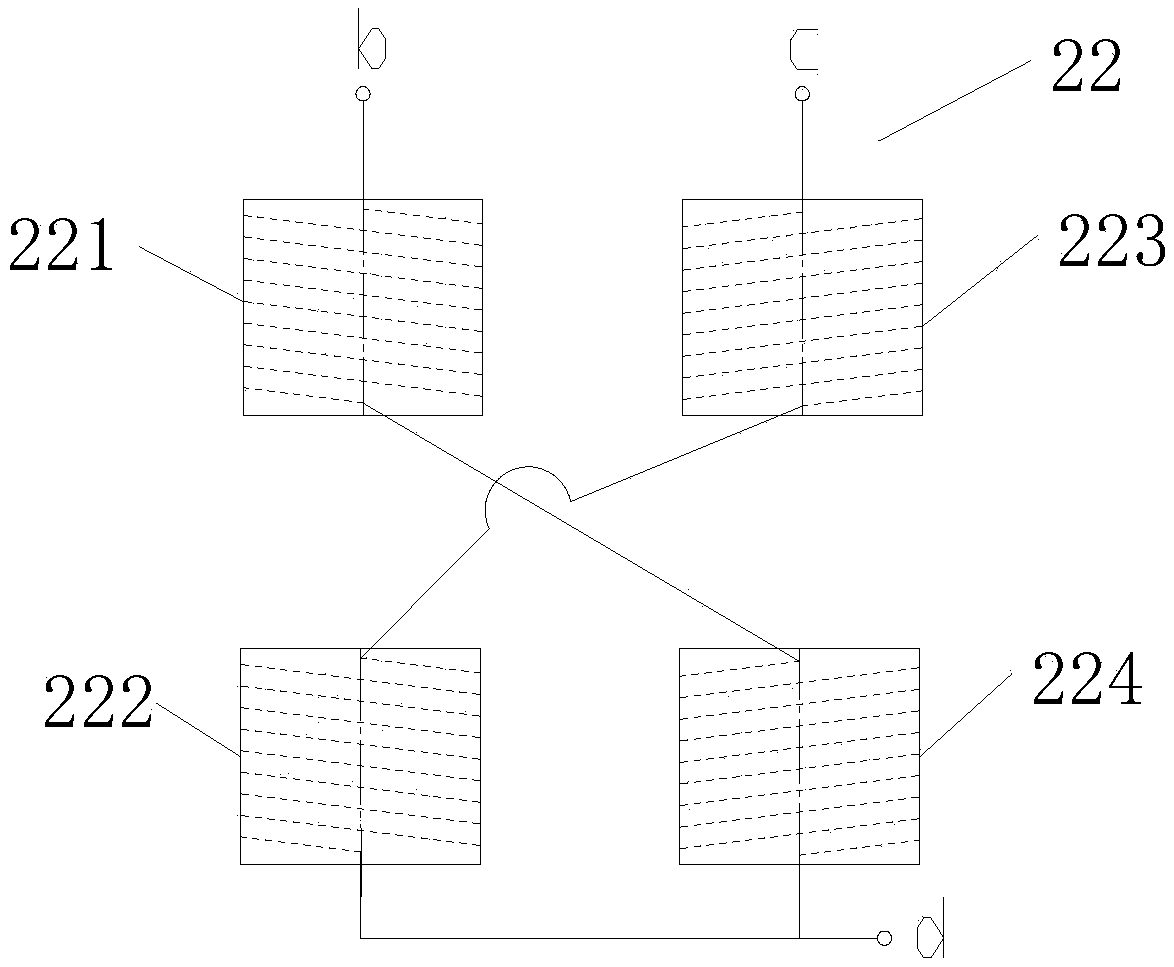

[0027] The number of turns of the first winding 221, the second winding 222, the third winding 223, and the fourth winding 224 of the M variable voltage coil 22 is 26 turns, and the first winding 221 and the fourth winding 224 are connected in series, and the first winding 221 The wires are wound in a clockwise direction, and the fourth winding 224 is wound in a counterclockwise direction. The second winding 222 and the third winding 223 are connected in series, the second winding 222 is wound in a clockwise direction, and the third winding 223 is wound in a counterclockwise direction. Therefore, the number of winding turns of the b-phase in the M variable low-voltage coil 22 is 52 turns, and the number of winding turns of the c-phase is 52 turns. By the winding method provided by the application, the winding circumferences of the b-phase and the c-phase are the same, thus Phase b and phase c have the same resistance, the fourth winding 224 of phase b is connected to the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com