Operation rod maintenance type integrated intelligent high-voltage switch

A high-voltage switch, one-piece technology, applied to switches operated by live operating rods, electric switches, high-voltage air circuit breakers, etc., can solve the difficulty of linkage testing between the switch part and the intelligent part, which affects the comprehensiveness and reliability of intelligence Sexuality, intelligent micro-signal damage and other problems, to achieve the effect of high cost performance, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

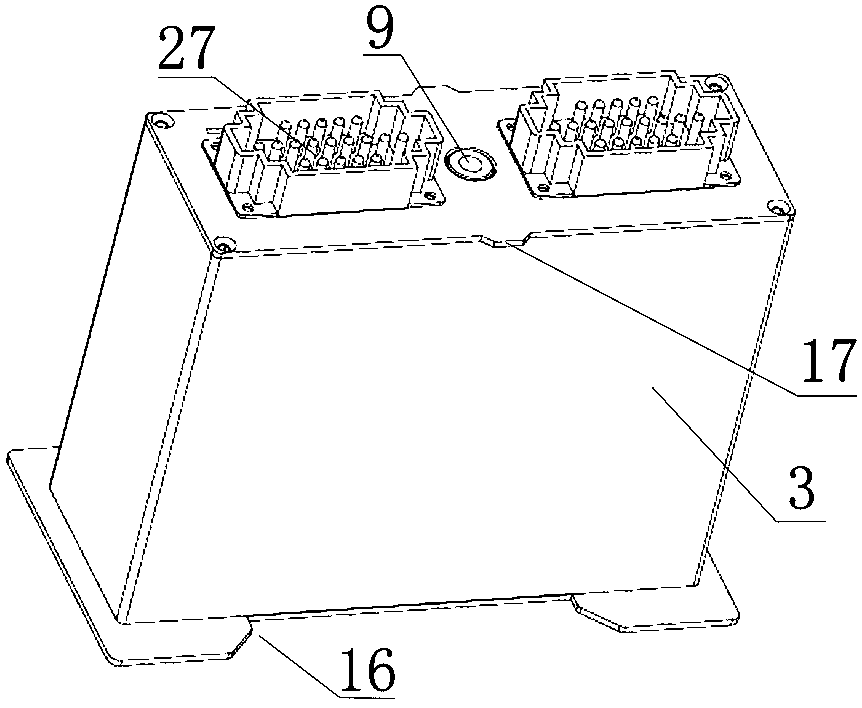

[0029] Such as image 3 with Figure 4 As shown, the structure of the locking mechanism is that the upper end of the rotating shaft 6 is provided with a threaded hole 9 opened in the vertical direction, and a bolt 10 is fixed on the upper side of the chamber 5, and the bolt 10 is arranged in the vertical direction and the upper end of the bolt 10 is fixed in the chamber. On the upper side of the cavity 5, the position of the bolt 10 corresponds to the threaded hole 9 at the upper end of the rotating shaft 6. When the intelligent module 3 is inserted into the cavity 5, the lower end of the bolt 10 is inserted into the threaded hole 9 at the upper end of the rotating shaft 6 and threaded with the rotating shaft 6. connect.

Embodiment 2

[0031] The structure of the locking mechanism is that the upper end of the rotating shaft is provided with two pin shafts, the two pin shafts are arranged along a radial direction of the cross section of the rotating shaft, and one end of the two pin shafts is respectively fixed on the sides of the upper end of the rotating shaft. A sleeve is fixed on the upper side, and a blind hole matching the rotating shaft is arranged in the sleeve. An annular groove is opened in the blind hole, and two concave holes matching the pin shaft are arranged on both sides of the blind hole along a radial direction. Groove, the upper end of the groove communicates with the annular channel. When the intelligent module is inserted into the cavity, the pin shaft at the upper end of the rotating shaft is inserted into the annular channel from the groove and rotated 90 degrees to lock and fix. The inner wall of the annular channel is at the position where the pin rotates 90 degrees. A baffle is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com