Crossing device for power transmission line

A technology of transmission lines and spanning racks, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of long construction period, manpower and time consumption, and only rebuilding of spanning racks, so as to save manpower, material and financial resources, save time, The effect of ensuring firmness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

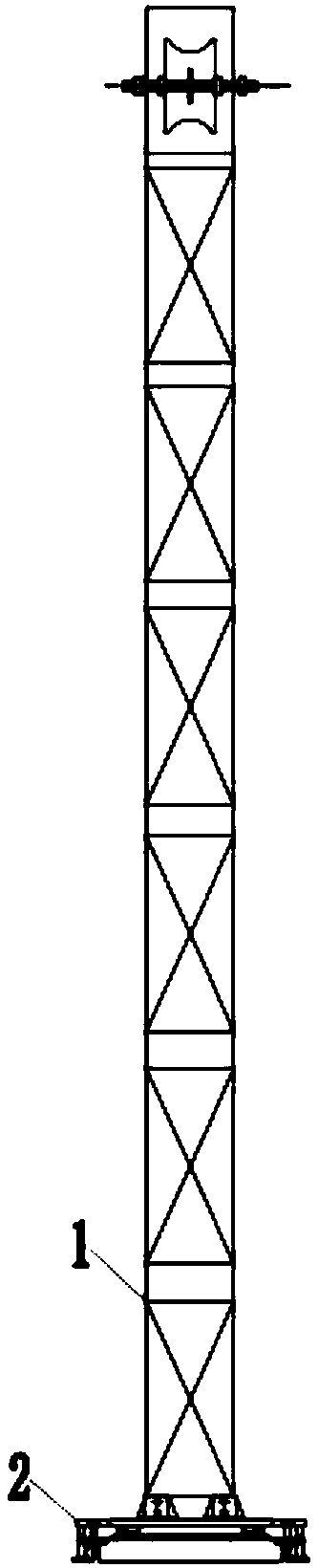

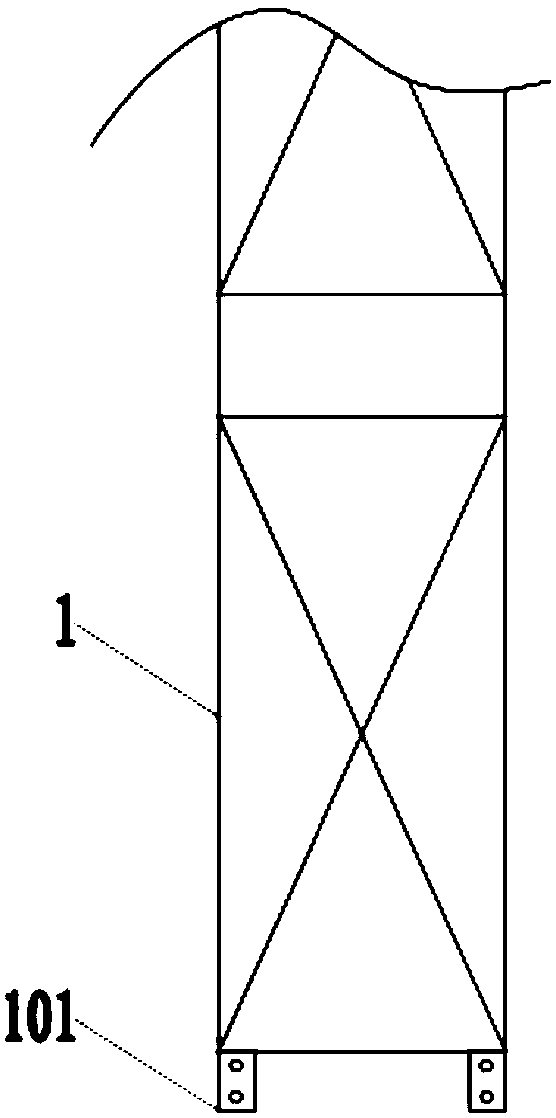

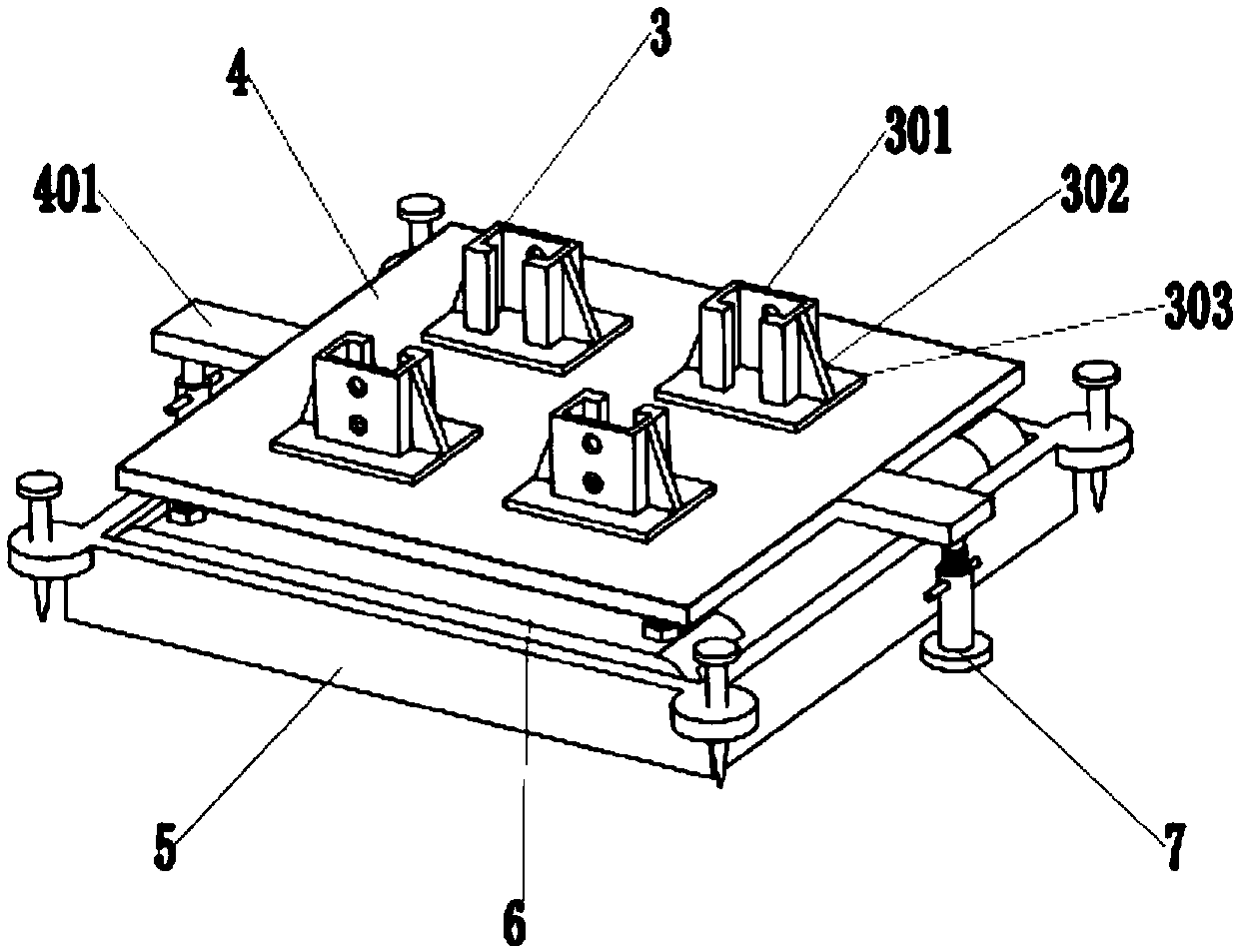

[0037] A spanning device for a power transmission line, comprising a spanning frame 1, a base 2 is provided at the lower end of the spanning frame 1, and the base 2 includes a socket sleeve 3, a mounting plate 4, a support frame 5, a rotating device 6, and lifting legs 7 , connecting piece 8, described support frame 5 is a rectangular frame structure, and described support frame 5 is provided with the rotating device 6 that is connected with it, and the upper end of described rotating device 6 is provided with mounting plate 4, and one end of described mounting plate 4 Connected to the rotating device 6 through the connecting piece 8, the mounting plate 4 is connected to the rotating device 6 through the first threaded rod 402, the two sides of the mounting plate 4 are provided with lifting legs 7, and the lifting legs 7 are arranged on the support On the outside of the frame 5 , the socket sleeve 3 is arranged on the upper surface of the mounting plate 4 , and the lower end of...

Embodiment 2

[0047] In order to further increase the firmness of the base, ground nails 501 are arranged around the support frame 5 .

[0048] The outer sides of the four corners of the support frame 5 are provided with lock plates 502, the lock plates 502 are provided with ground nails 501, and the surroundings of the support frame 5 are fixed by the ground nails 501, which increases the firmness of fixing. performance, making it safer to use.

[0049] After the base 2 is fixed on the ground, ground nails 501 are knocked into the ground to fix the base 2, and the rest of the steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com