Functional film embedded structure and forming process thereof

A molding process and functional film technology, which is applied to electrical components, casings/cabinets/drawer parts, sealed casings, etc., can solve the problem of increasing air humidity of electronic components, unreasonable device design, and the impact of electronic components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

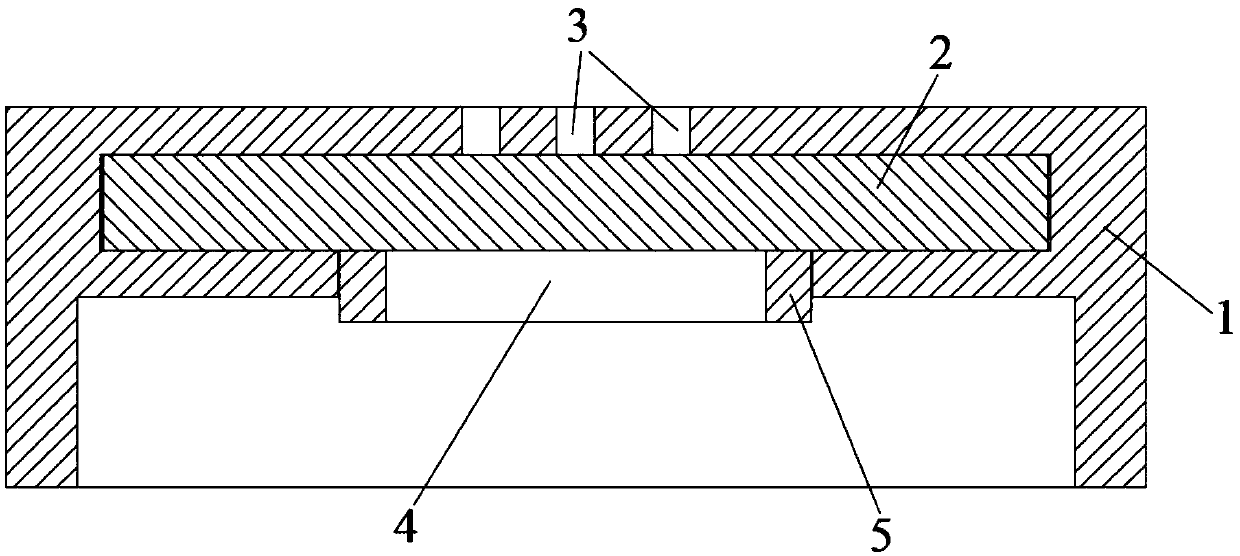

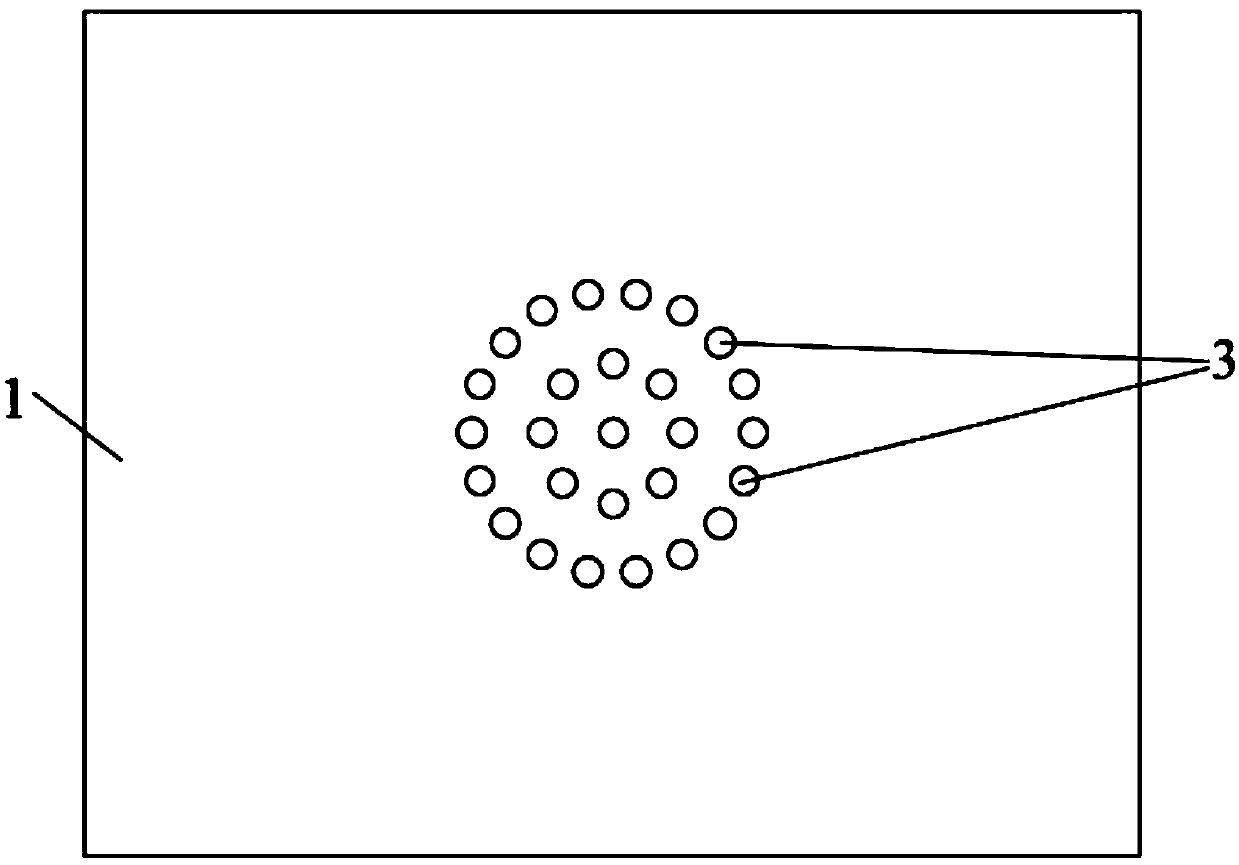

[0036] Such as Figure 1-4 As shown, a functional film embedded structure includes a structure 1, a functional film 2, a first through hole 3 and a second through hole 4, the functional film 2 is embedded in the structure 1, and the first through hole 3 is set in the The outer wall of the structure 1, the second through hole 4 is arranged on the inner wall of the structure 1, the first through hole 3 corresponds to the second through hole 4, and the functional film 2 is arranged between the first through hole 3 and the second through hole 4 . The electronic components are arranged in the box or box with this structure in the present invention. When the electronic components are working, because the electronic components have their own resistance, heat will be generated after the current is turned on, and these hot gases pass through the second channel in turn. The hole 4, the functional film 2, and the first through hole 3 are evacuated to the external environment. At the sam...

Embodiment 2

[0046] like Figure 1-4 Shown, a kind of molding process of the functional film embedded structure of embodiment 1 comprises the following steps:

[0047] S1. Prepare the prefabricated part, place the functional film 2 on the supporting ring 5, and complete the preparation of the prefabricated part;

[0048] S2, placing the prefabricated part in the mold, and the protrusions in the mold support and position the support ring 5;

[0049] S3, placing the mold in the injection molding machine;

[0050] S4, start the injection molding machine, inject raw materials into the mold, and complete the injection molding;

[0051] S5, close the injection molding machine, and cool down the mold;

[0052] S6, open the mold, and take out the product with the embedded structure of the functional film;

[0053] Wherein, the order of steps S2 and S3 can be interchanged.

[0054] Preferably, in step S1, the functional film 2 is fixed on the support ring 5 by liquid glue or double-sided adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com