Tank, and electrohydraulic compact assembly having a tank

A compact and fuel tank technology, which is applied in the direction of fuel supply tank devices, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of large fuel tank volume, and achieve the effect of reducing installation space and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

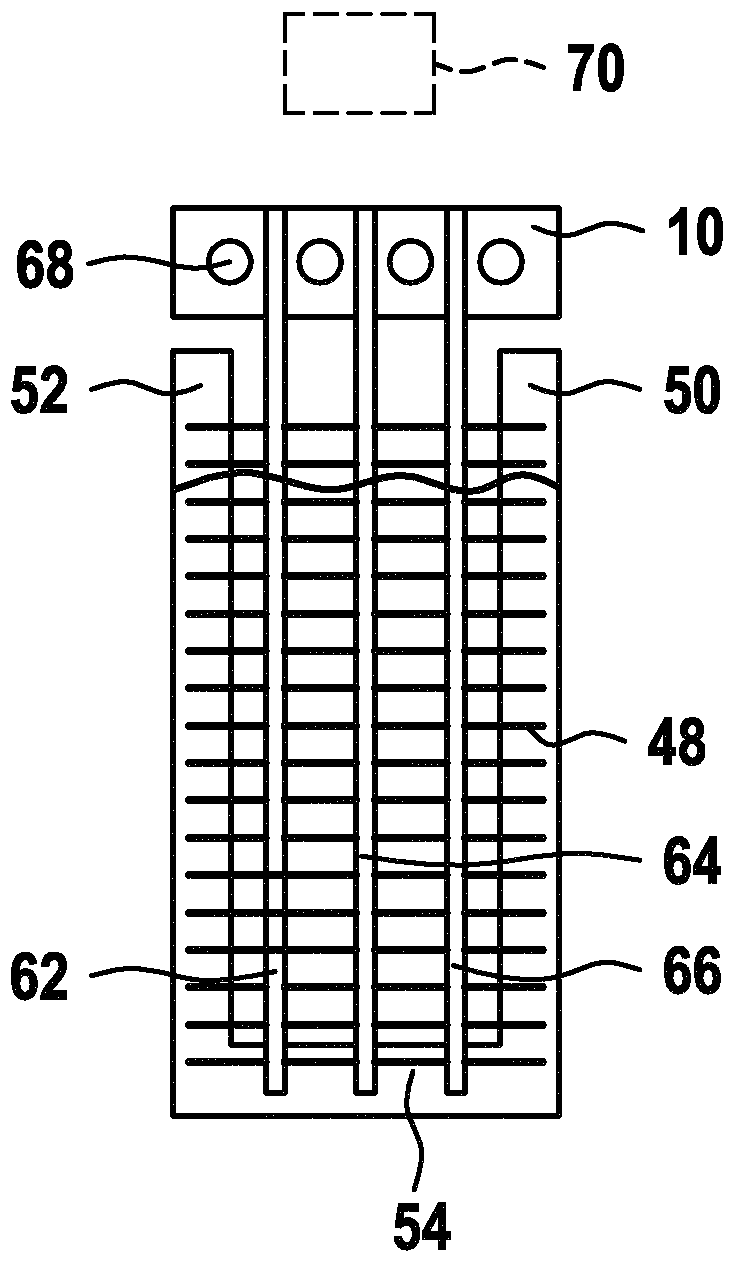

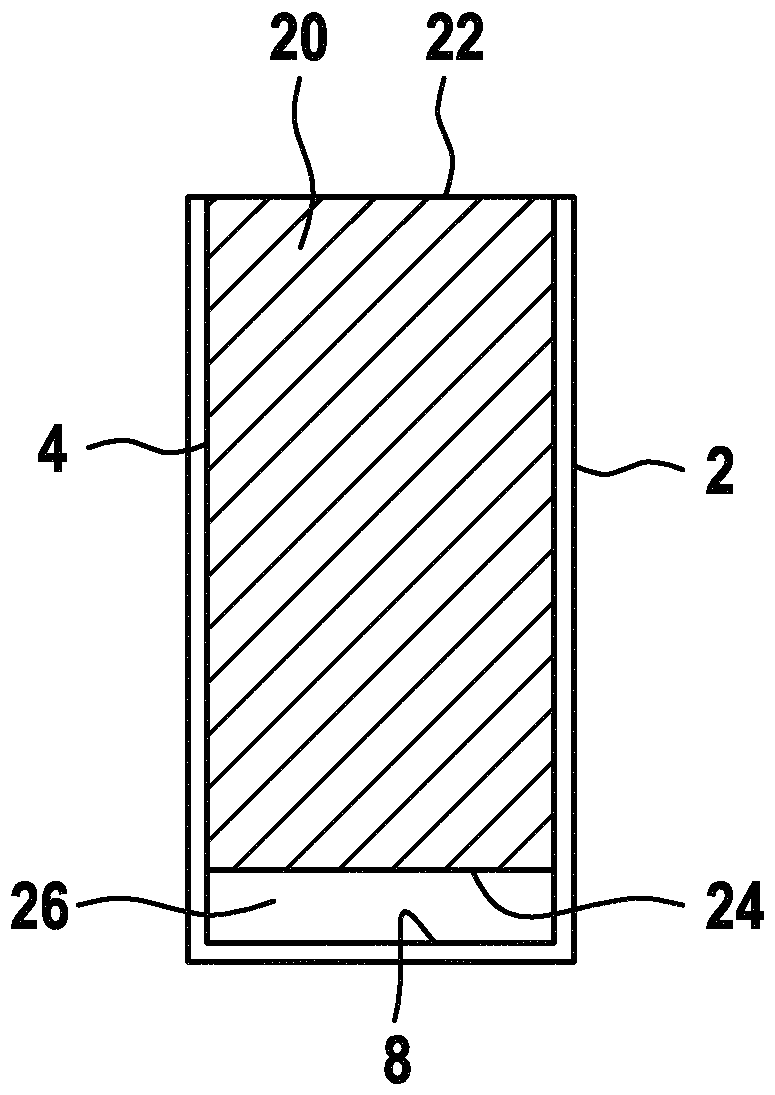

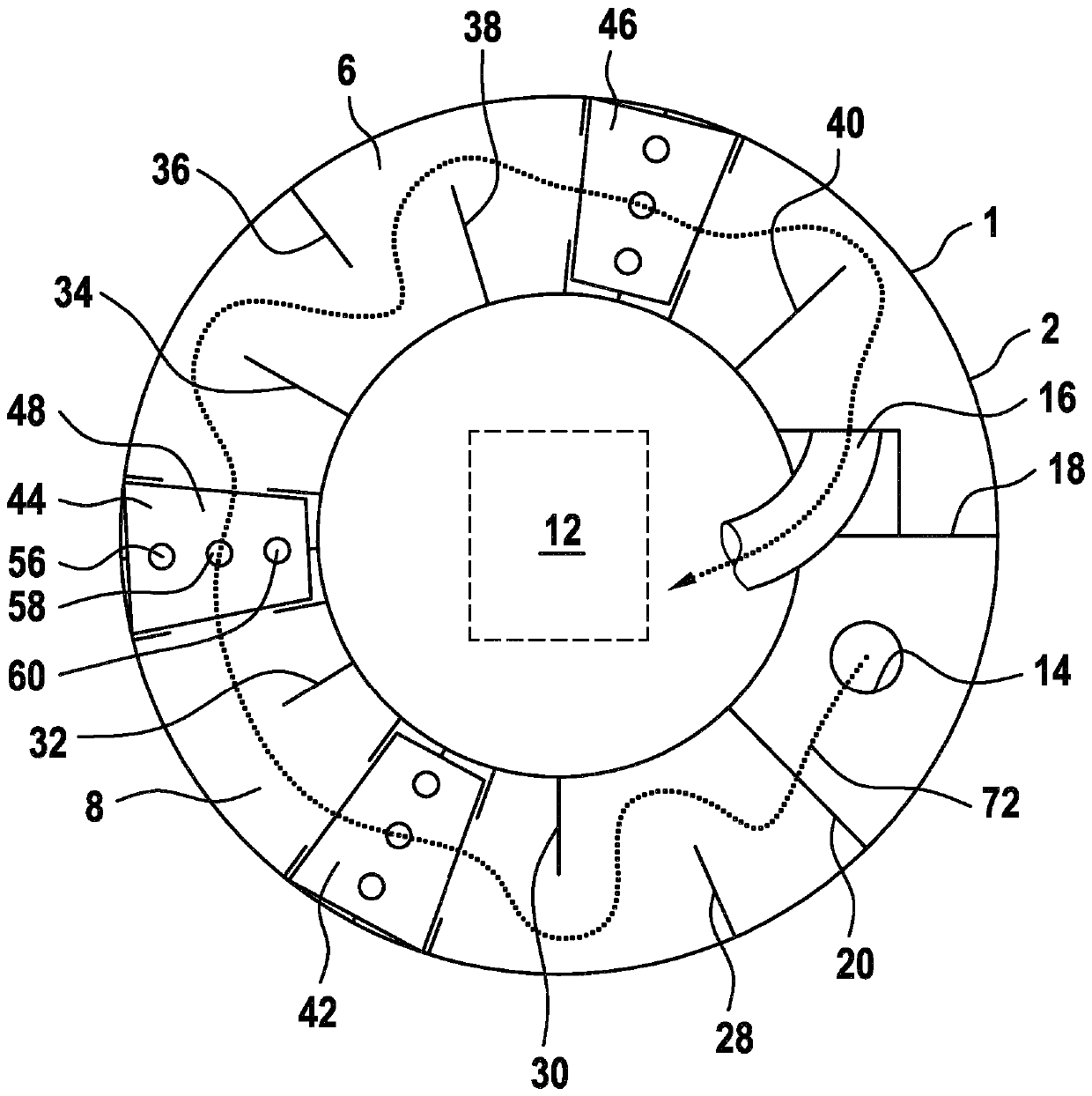

[0027] according to figure 1 A fuel tank 1 for a compact unit has an approximately cylindrical outer wall 2 which surrounds an approximately cylindrical inner wall 4 , wherein the walls 2 , 4 are arranged approximately coaxially to one another. Walls 2 and 4 jointly delimit an annular cavity 6 . The annular space is delimited on the bottom side by an annular bottom wall 8 . The walls 2 and 4 extend approximately in the vertical direction, wherein, viewed in the vertical direction, the bottom wall 8 is then arranged below. Above, the annular chamber 6 can be closed by a top wall, not shown, which can be formed, for example, by a closure cover 10, see figure 2 . exist figure 1 In the cavity defined by the inner wall 4, a hydraulic pump 12 can be arranged, which hydraulic pump according to figure 1 It is shown schematically with dashed lines. The hydraulic pump 12 can discharge oil into the annular space 6 via a load and a return connection or supply connection 14 connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com