Electric motor for hand-held power tool

A hand-held power tool, electric motor technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve problems such as increased short circuit, electric motor damage, user damage, etc., to achieve the effect of reducing dust and/or particle intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

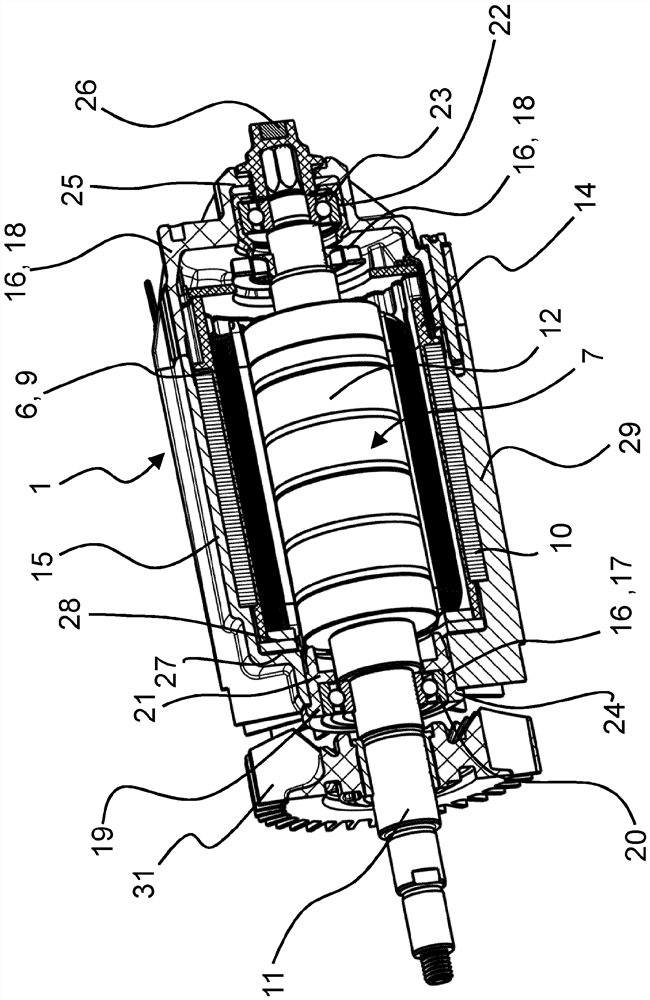

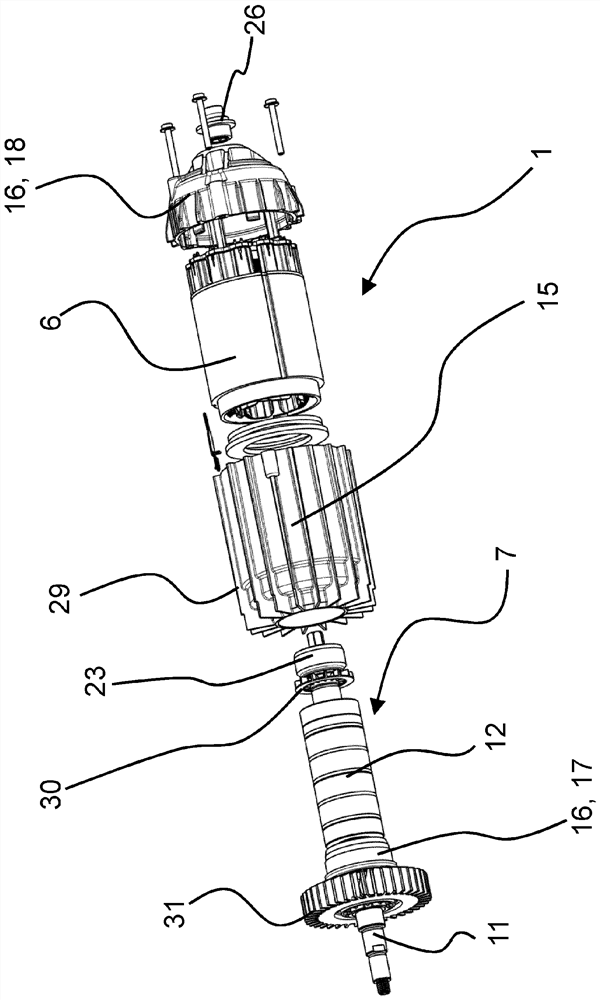

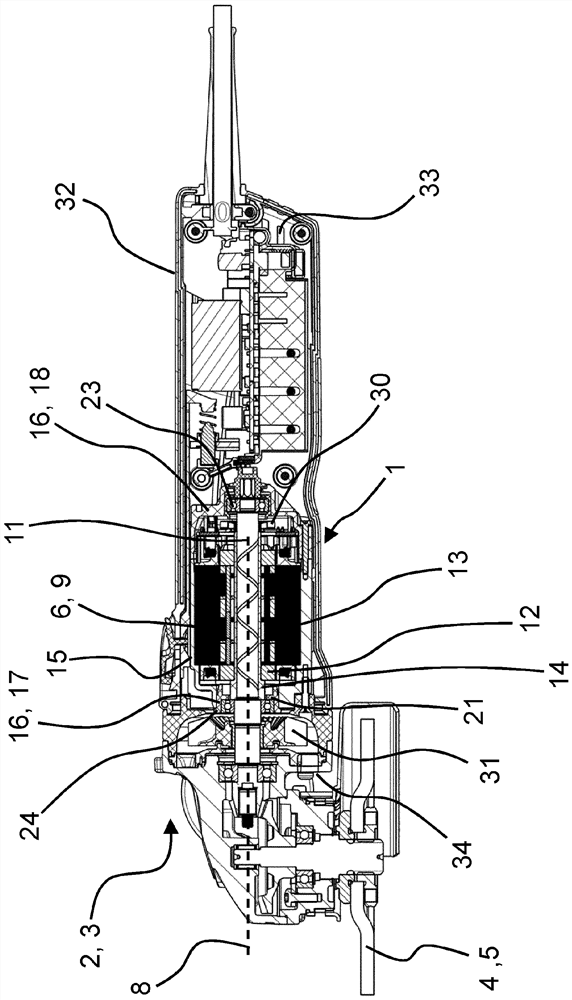

[0026] figure 1The electric motor 1 of the wired hand-held power tool 2 is shown in a sectional view along the longitudinal section, which in the illustrated embodiment is designed as an angle grinder 3, which is generally operated at 80 V and 280 V. voltage between V to operate. The electric motor 1 of the hand-held power tool 2 is designed as an EC-motor and drives the grinding wheel 5 , which is currently designed as a plug-in tool 4 . The electric motor 1 includes a stator 6 and a rotor 7 , which is mounted within the stator 6 so as to be rotatable about an axis of rotation 8 . Here, the stator 6 includes a plurality of windings 9, which are supplied with a voltage by means of lines. In this case, the windings 9 are accommodated in the stator lamination stack 10 and are substantially electrically insulated with respect to the stator lamination stack. This is achieved by maintaining the air- and electrical gap and separating the windings 9 from the stator lamination stac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com