Magnetic angular position sensor circuit

A technology of magnetic sensor and sensor device, which is applied in converting sensor output, using electromagnetic/magnetic device to transmit sensor components, instruments, etc., can solve the problems of high manufacturing cost of magnets and increasing cost of angular position sensor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

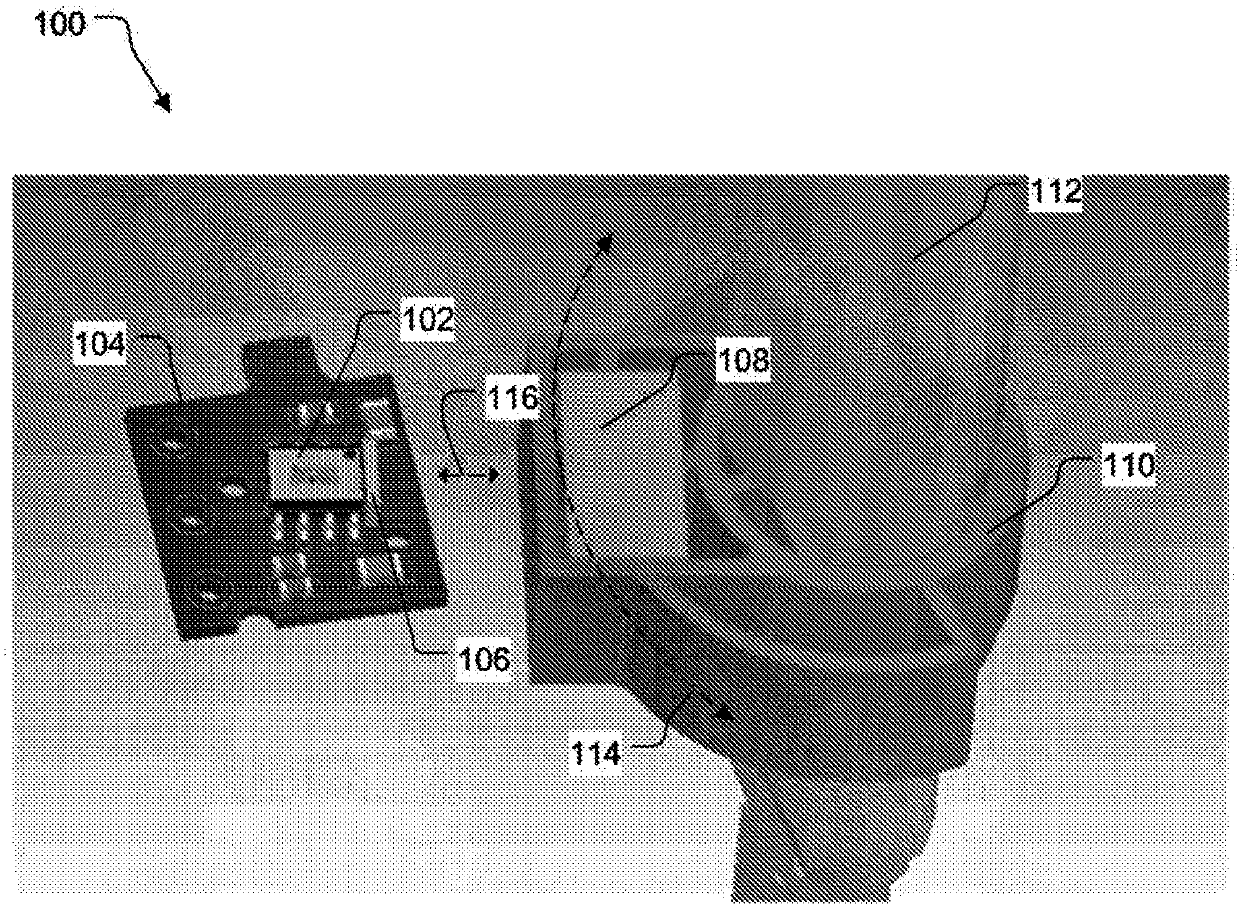

[0012] figure 1 An exemplary sensor device 100 is shown. The exemplary sensor device 100 may include a magnetic sensor 102 (eg, a Hall effect sensor or a magnetoresistive sensor) mounted to a printed circuit board 104. In addition, the magnetic pole element 106 may be arranged close to the magnetic sensor 102. In one example, the magnetic pole element 106 is arranged close to or in close proximity to the magnetic sensor 102. The pole element 106 may be made of ferromagnetic material. For example, the magnetic pole element 106 may be made of steel (for example, low carbon steel AISI1010, iron, nickel, cobalt, etc.).

[0013] The sensor device 100 may also include a movable magnet 108. The movable magnet 108 may be positioned adjacent to the magnetic sensor 102. In one embodiment, the movable magnet 108 is held or positioned in the magnet holding element 110. The magnet holding element 110 may be coupled to the shaft 112. In one embodiment, the magnet holding element 110 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com