Novel powder concentrator

A powder concentrator and a new type of technology, applied in the direction of swirl device, grain processing, etc., can solve the problems of low selection rate of fine powder and reduced selection rate, and achieve the effect of improving the selection rate of fine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

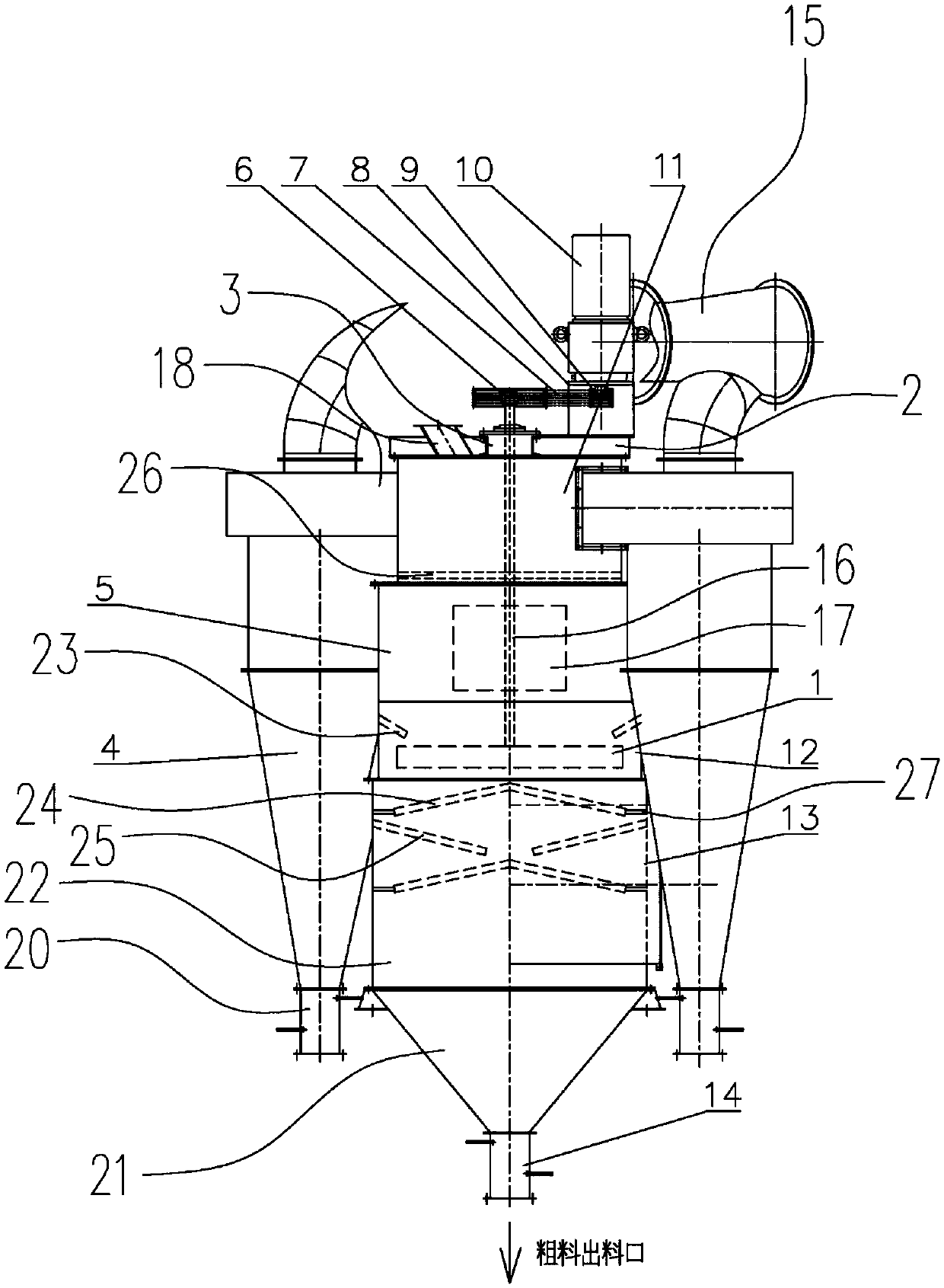

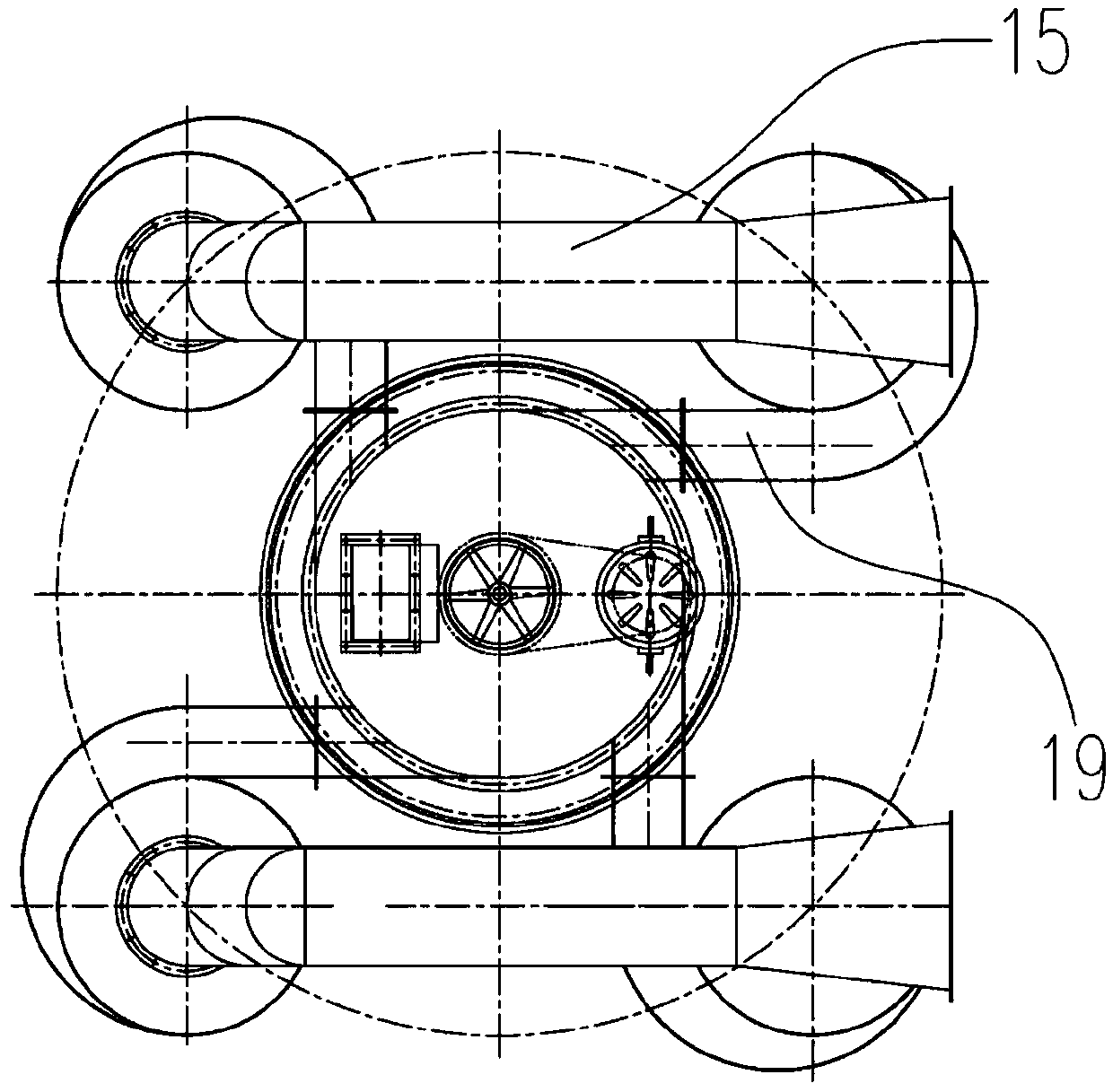

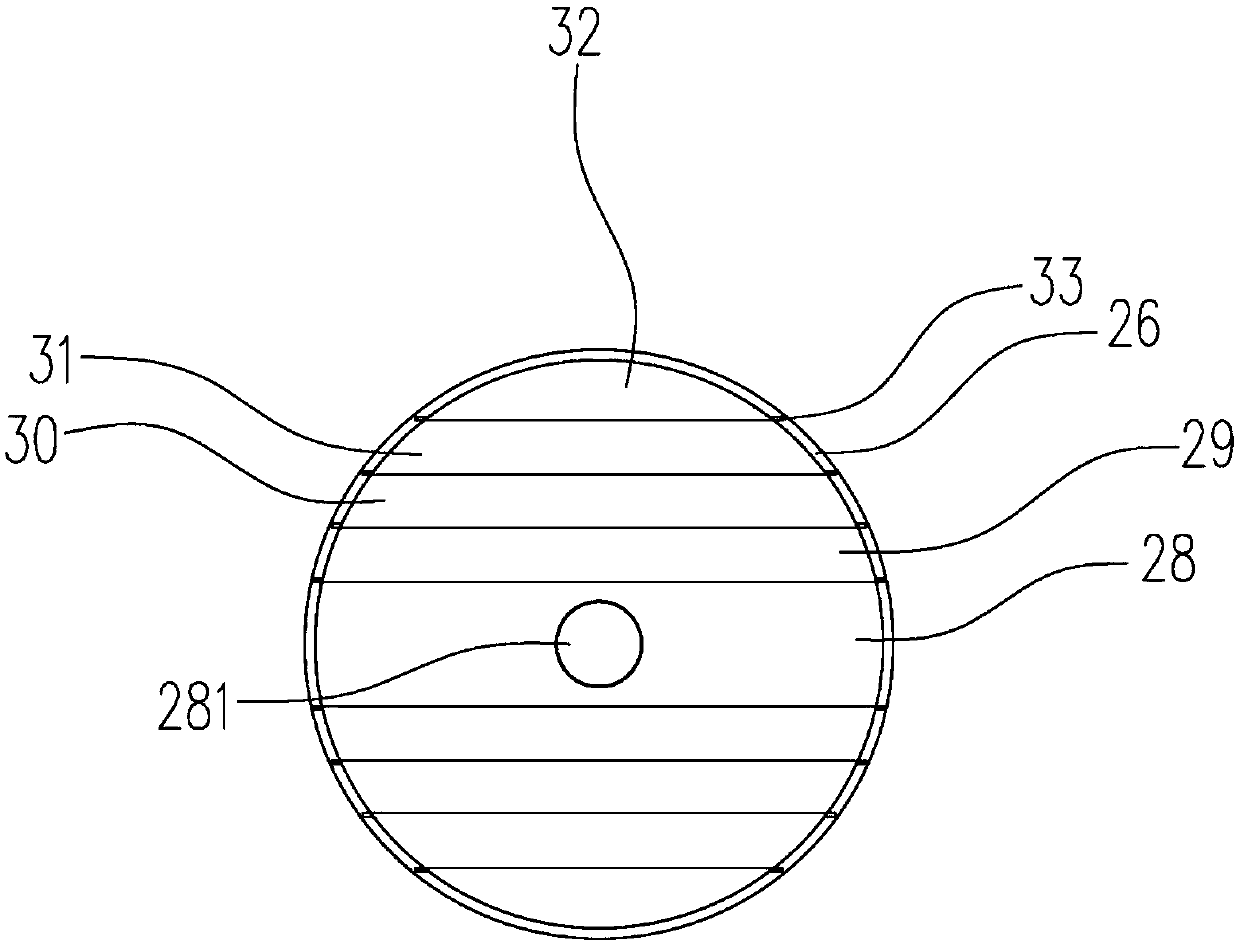

[0014] Such as Figure 1~3 As shown, a new powder separator includes a cutting cylinder 12, a cutting blade 1, a powder selecting cylinder 5, an air distribution cylinder 11, a drive assembly, a main shaft 16, a wind wheel 17, a top plate 2, a bearing seat 3, a cyclone 4, Air inlet chamber 13, first flap valve 20, second flap valve 14, main air duct 15, mixing barrel 22, guide assembly, conical discharge hopper 21, feed channel 18 and suction duct 19; top plate 2 The air distribution cylinder 11 is fixed below the air distribution cylinder 11, and four air suction pipes 19 distributed equiangularly along the circumferential direction are connected to the outer circumferential surface of the air distribution cylinder 11. Each air suction pipe 19 is tangent to the inside of the air distribution cylinder 11. , the outside of the air distribution tube 11 is also provided with four cyclone tubes 4, the air inlets of the four cyclone tubes 4 are respectively connected with the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com