Raw material screening equipment for biological pharmacy

A technology of biopharmaceutical and screening equipment, applied in the direction of sieve, solid separation, grid, etc., can solve the problems of long time required, increase the production cost of manufacturers, increase the workload of manufacturers, etc., and achieve good impurity removal. Handling, easy drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

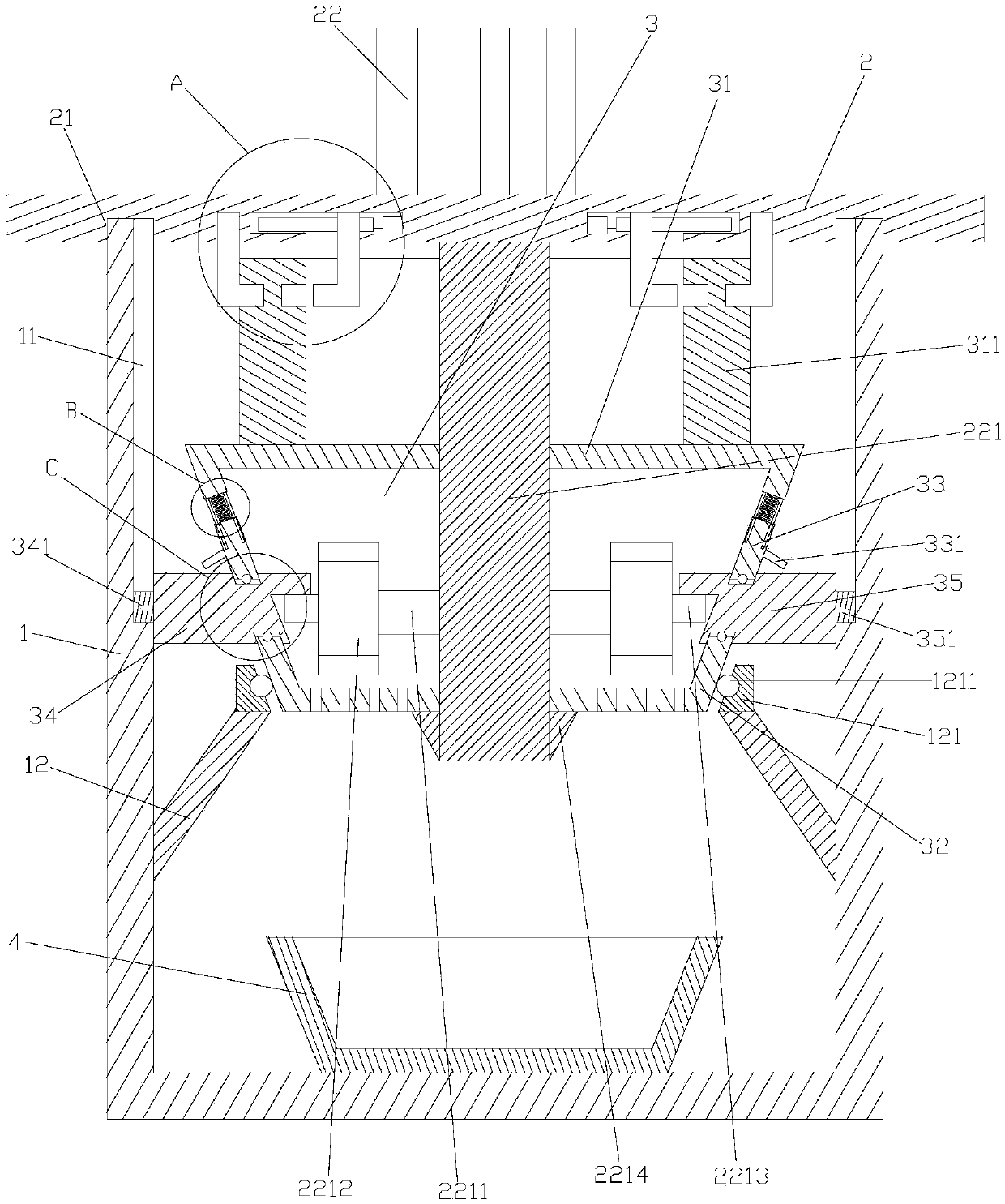

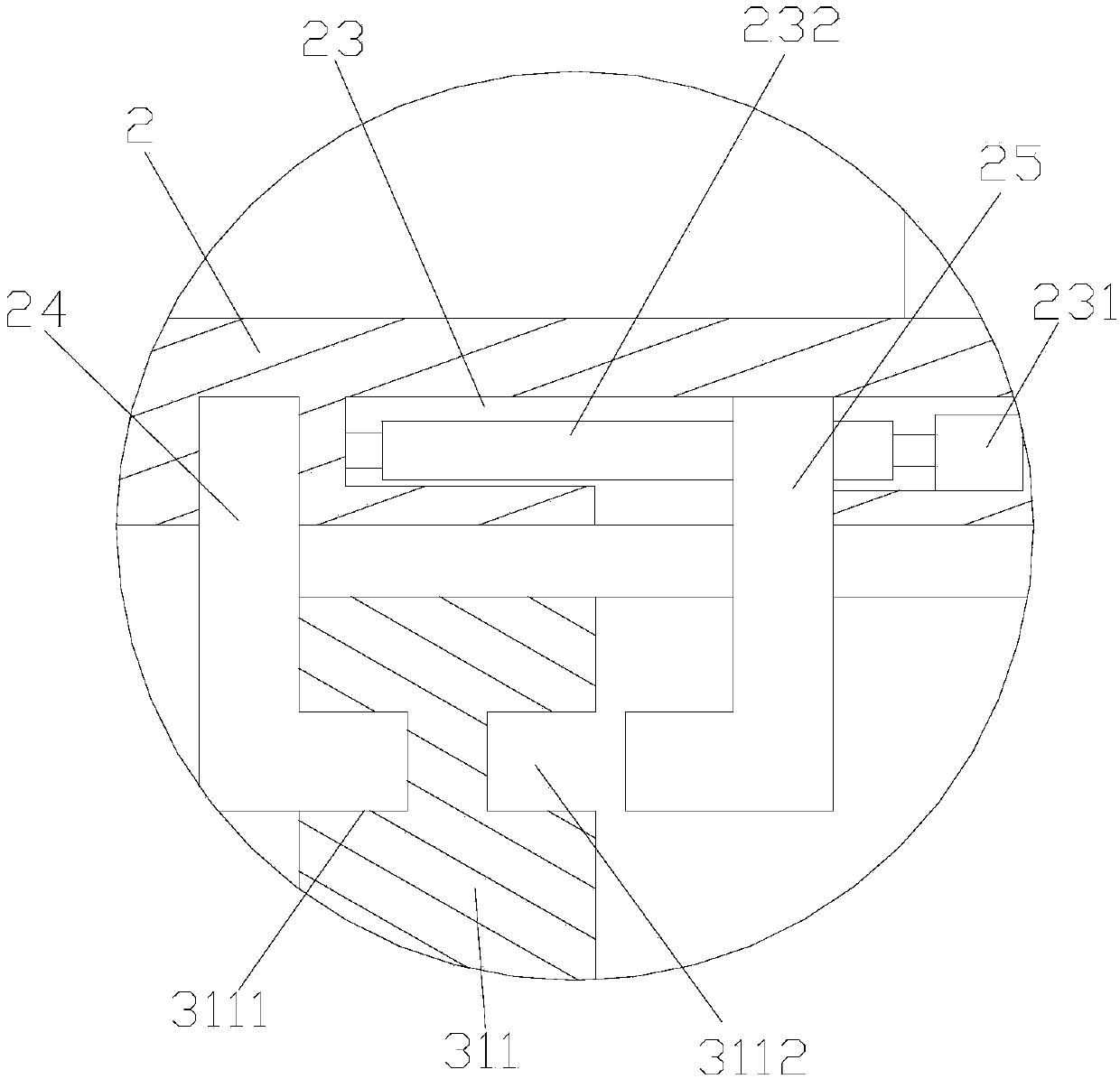

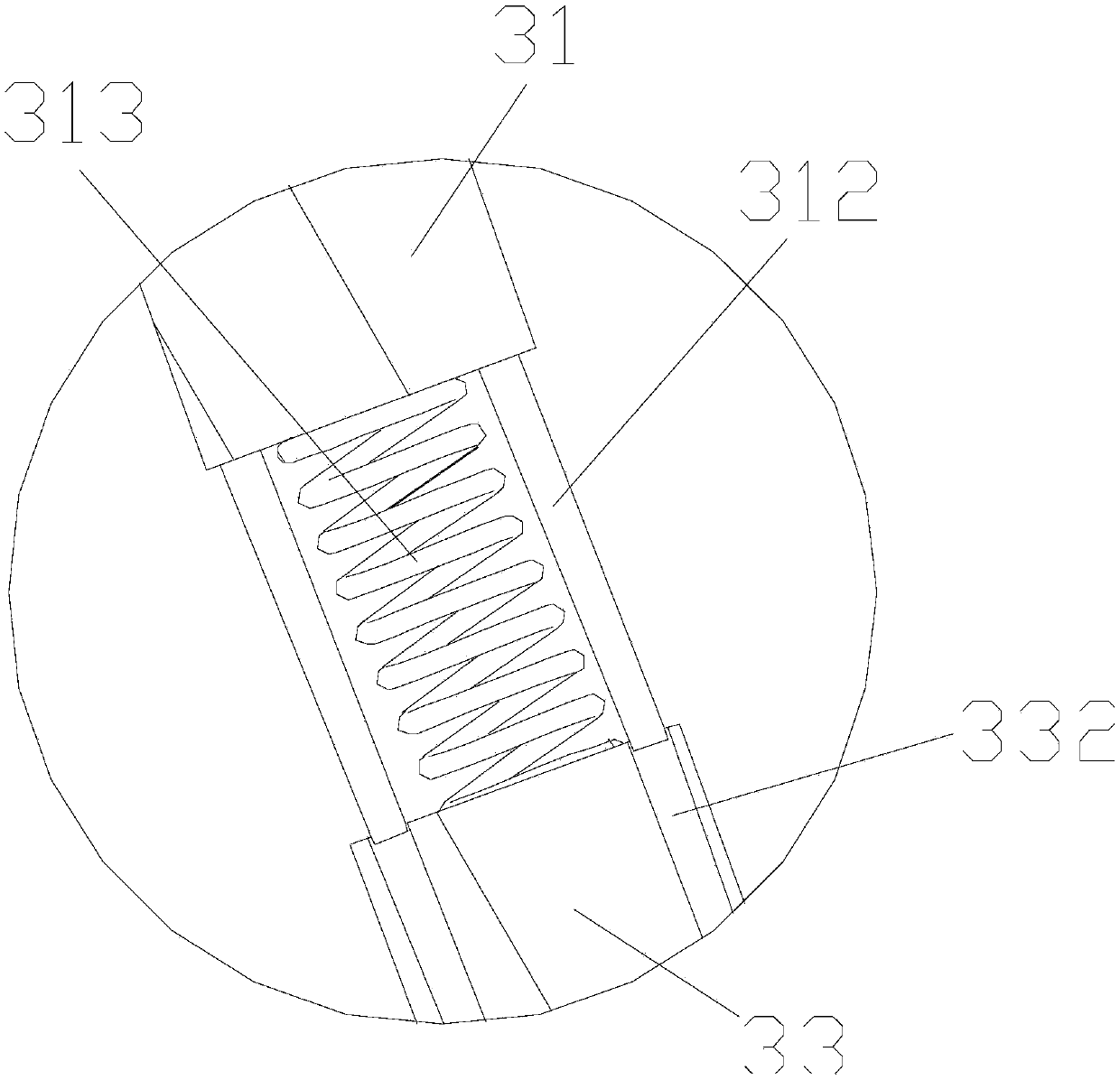

[0032] Such as Figure 1-7 As shown, a raw material screening equipment for biopharmaceuticals includes a box body 1, a box cover 2 arranged on the box body 1, a loading box 3 arranged in the box body 1, and a box body arranged on the box body 1. The receiving box 4 at the bottom of the body 1; the raw materials are placed in the loading box 4 to screen and remove impurities; the box cover 2 is provided with a driving motor 22, and the output shaft of the driving motor 22 is fixedly connected with a transmission Shaft 221, the loading box 3 is fixedly connected to the transmission shaft 221; the driving motor 22 is fixedly connected to the top of the case cover 2, and the driving motor 22 works to drive the transmission shaft 221 to rotate, and the rotation of the transmission shaft 221 drives the loading box 3 Rotate so that the raw materials in the loading box 3 stick to the inner wall of the loading box 3 under the centrifugal force generated by the rotation of the loading ...

Embodiment 2

[0043] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that: the left transmission plate 34 is provided with a second connection block 341, and the right transmission plate 35 is provided with a connecting piece that matches the second transmission block 341. Groove 351, the second connection block 341 is provided with a plurality of convex strips 3411, the convex strips 3411 are rectangular structures, the convex strips 3411 are uniformly arranged on the second connection block 341, the second connection The block 341 is also provided with a first limiting protrusion 3412, the top surface of the first limiting protrusion 3412 is an arc-shaped structure, and the connecting groove 351 is provided with a Cooperating second limiting protrusion 3511, the second limiting protrusion 3511 is made of elastic material; the second limiting protrusion can be made of rubber; when the transmission plate is loaded into the loading box, Load the left a...

Embodiment 3

[0045] Such as Figure 9-10 As shown, the difference between this embodiment and Embodiment 1 is that: the side wall of the box body 1 is provided with a discharge port 13, and the discharge port 13 is located on one side of the material receiving box 4, and the discharge port 13 is connected to the material receiving box 4, the material receiving box 4 can enter and exit the box body from the discharge port 13; the bottom of the box body 1 is provided with a feeding device for driving the material receiving box 4 to move, and the material receiving box 4 is detachably connected On the feeding device; the impurities falling from the raw materials in the loading box 3 fall into the receiving box 4, so as to avoid the inconvenience of impurity collection caused by the impurities falling directly on the bottom of the box, so that the impurities are uniformly collected in the receiving car 4, it is convenient for the unified treatment of impurities in the receiving vehicle; when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com