Diamond rope saw cutting method for blast furnace residual iron

A technology of diamond wire saw and cutting method, which is applied in the direction of metal sawing equipment, blast furnace, blast furnace details, etc. It can solve the problems of affecting life and reducing the efficiency of wire saw, so as to improve service efficiency and life, improve smoothness, and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

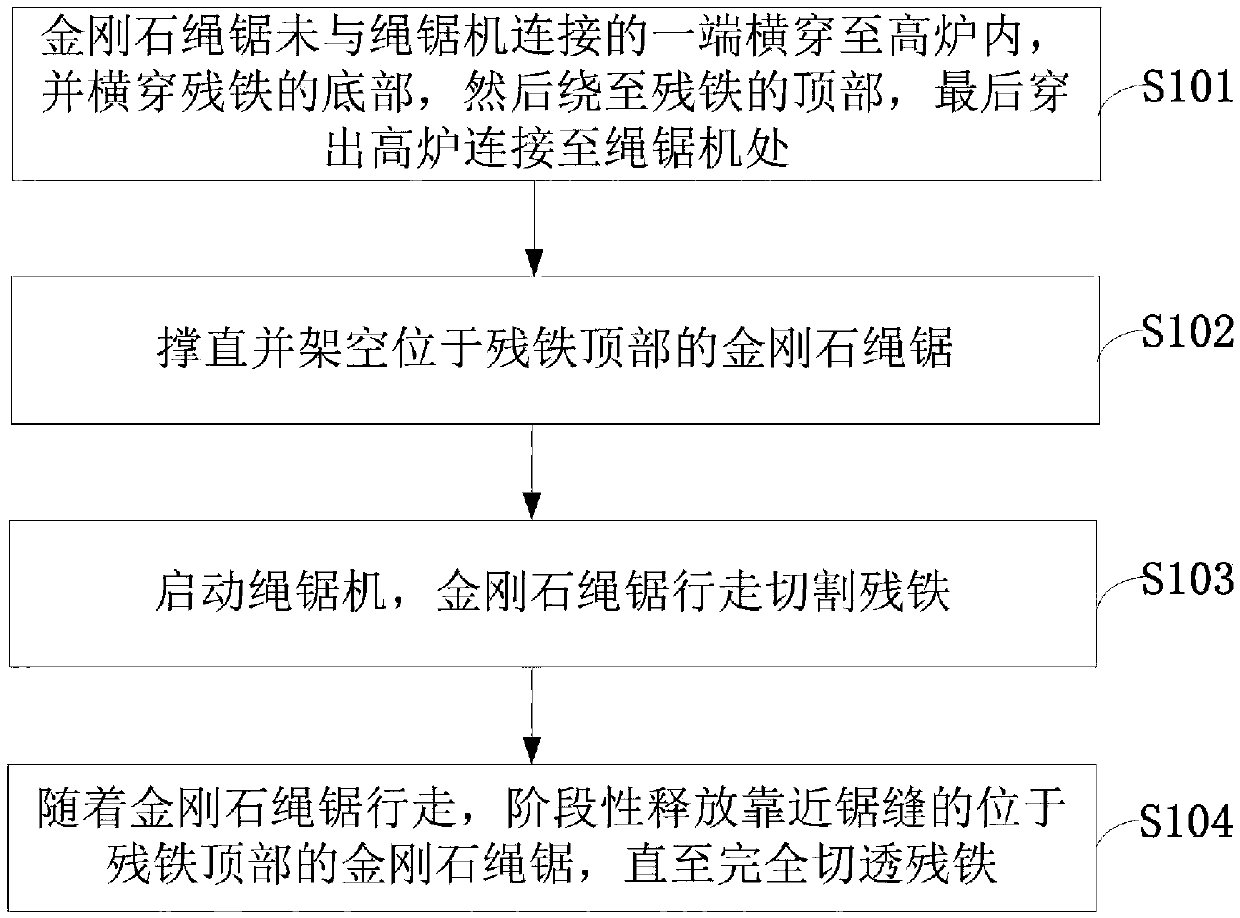

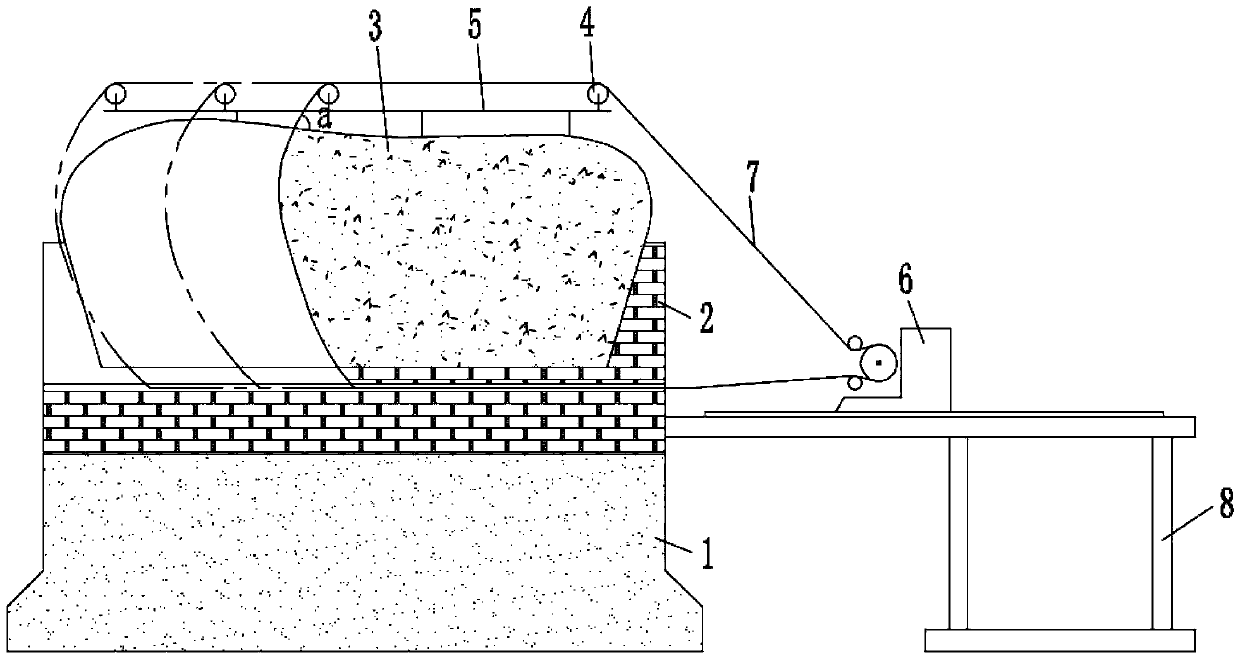

[0044] see Figure 1 to Figure 2 , the invention provides a diamond wire saw cutting method for blast furnace residual iron, comprising:

[0045] To install the wire saw:

[0046] Step S101 The end of the diamond wire saw 7 that is not connected to the wire saw machine 6 crosses into the blast furnace 1, crosses the bottom of the residual iron 3, then winds to the top of the residual iron 3, and finally passes through the blast furnace 1 to connect to the wire saw machine 6 places;

[0047] Step S102 straightens and lifts the diamond wire saw 7 at the top of the residual iron 3;

[0048] Cutting residual iron 3:

[0049] Step S103 starts the wire saw machine 6, and the diamond wire saw 7 moves to cut the residual iron 3;

[0050]...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap