Sheet gear end face polishing and chamfering device and operation method thereof

A thin-film gear and end-face technology, applied in the field of thin-film gear end-face polishing and chamfering equipment, can solve the problems of high technical requirements for operators, high processing costs, low efficiency, etc., and achieve simple maintenance, high production efficiency, and improved performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

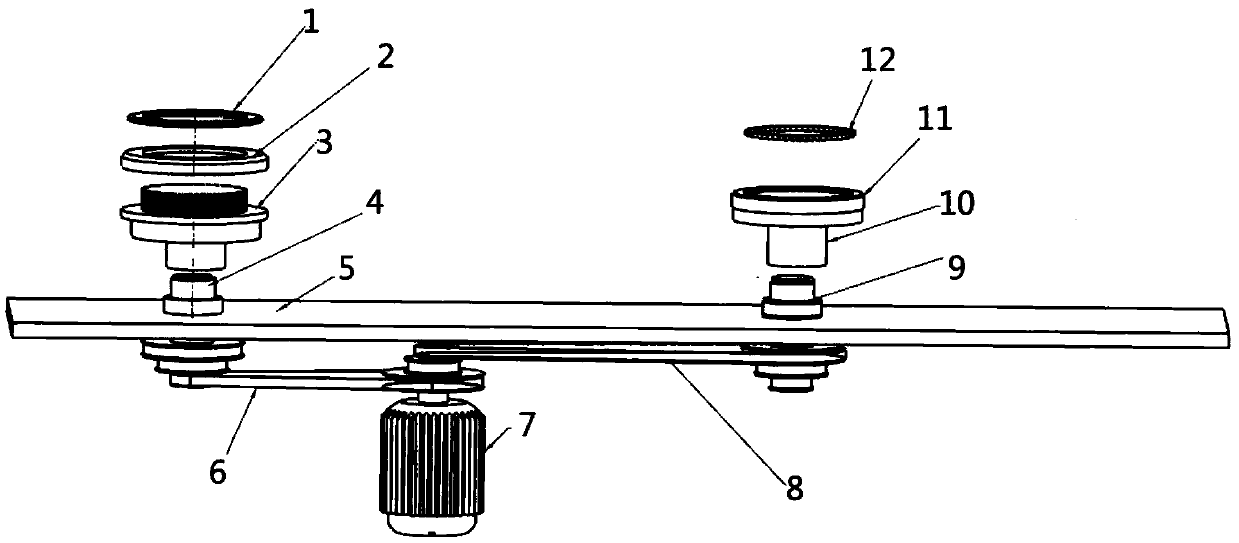

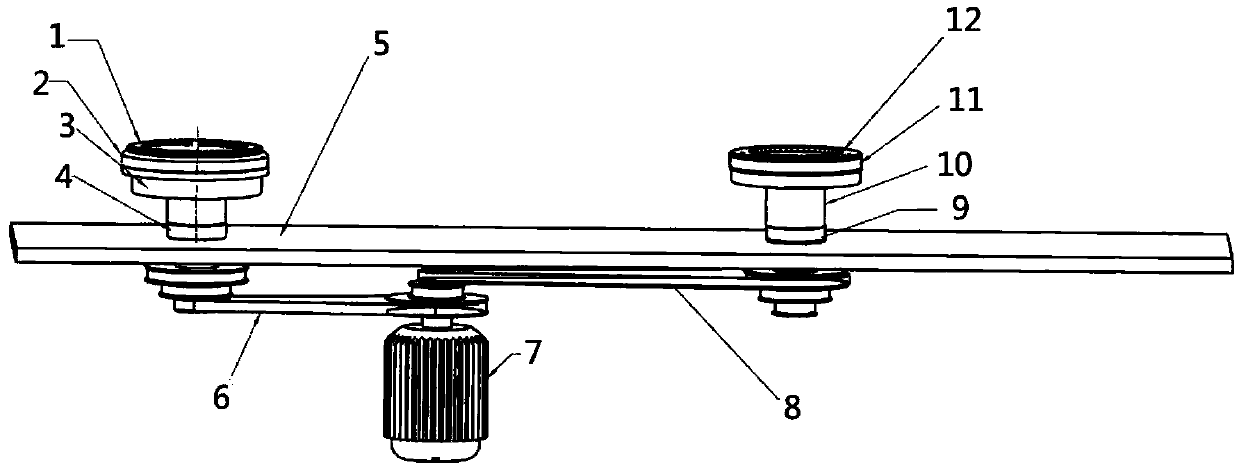

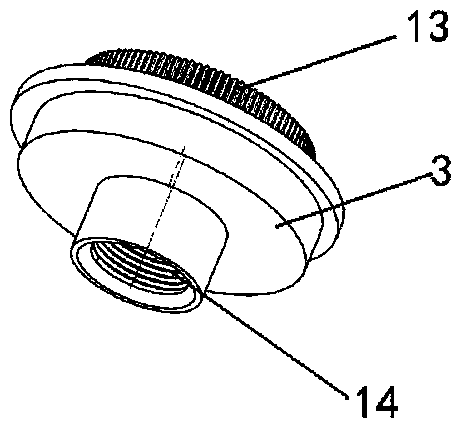

[0035] Such as Figure 1-9 As shown, a thin-plate gear end surface polishing and chamfering equipment provided by the present invention includes a worktable 5, on which a tooling main body A3, a tooling main body B10, a rotating shaft A4, a rotating shaft B9 and a motor 7 are arranged; The rotating shaft A4 and the rotating shaft B9 are installed on the workbench 5, and there is a gap between the two; the tooling main body A3 and the tooling main body B10 are located above the workbench 5; the motor 7 is located below the workbench 5; One end of the rotating shaft A4 is connected with the tooling main body A3, and the other end is connected with the motor 7 through the transmission belt A6; one end of the rotating shaft B9 is connected with the tooling main body B10, and the other end is connected with the motor 7 through the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com