An automatic batching and pickling control system and process for gelatin bone powder

An automatic batching and control system technology, applied in the preparation of animal glue or gelatin, etc., can solve the problems of large interference from human factors, low precision of acid mixing, uncontrollable indicators, etc., to reduce uncertain factors and fully pickling , control the effect of stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An automatic batching and pickling control system for gelatin bone powder.

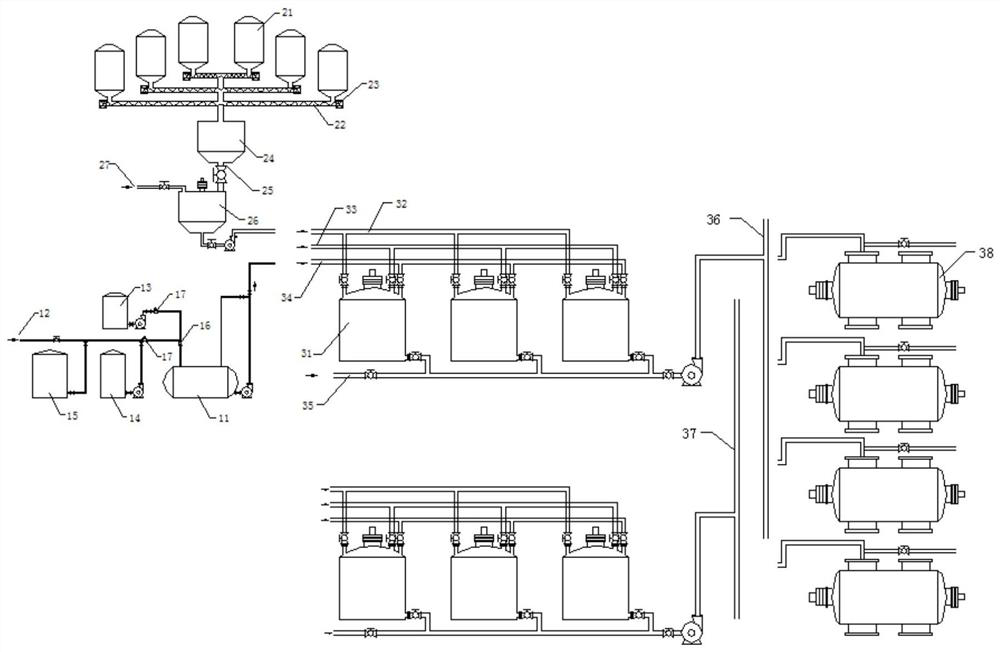

[0042] refer to figure 1 , the system consists of:

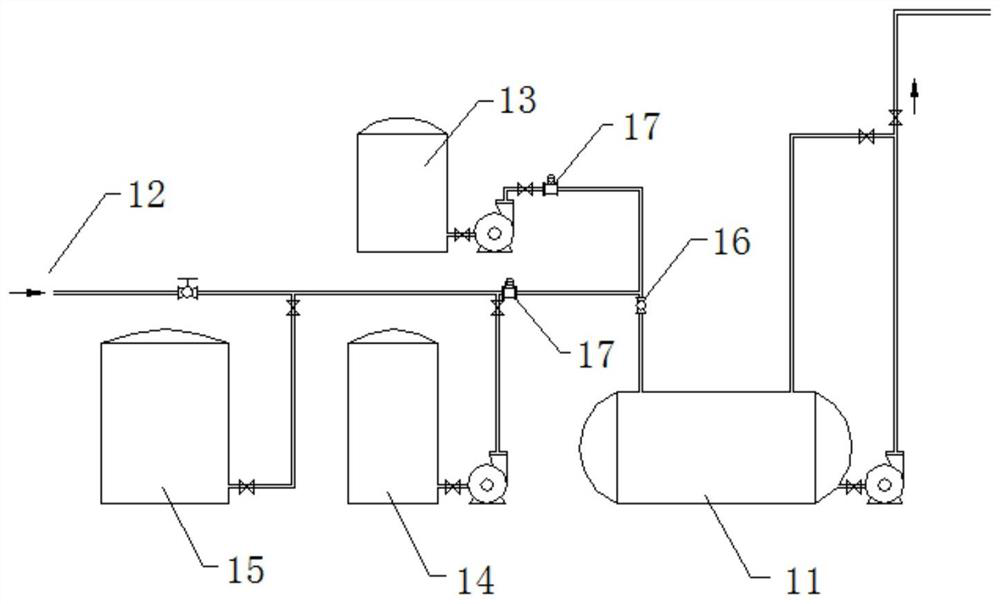

[0043] Acid distribution device, including acid distribution tank 11, water inlet 12, original acid tank 13, recovery acid tank 14, water inlet 12, original acid tank 13, recovery acid tank 14, water or acid liquid is delivered through pipelines, and the pipelines meet After being located at one place, it is connected to the acid distribution tank 11 through the online mixer 16 installed there. The outlets of the acid distribution tank 11, the original acid tank 13 and the recovery acid tank 14 are all equipped with solenoid valves and delivery pumps. The original acid tank 13 1. A flow meter 17 is installed at the outlet of the recovery acid tank 14. After the pipeline for conveying water and the pipeline for conveying and recovering acid converge in one place, the flowmeter 17 at this place is connected to the in-line mixer 16. A dual liq...

Embodiment 2

[0052] An automatic batching and pickling control process for gelatin bone powder.

[0053] This technology is applied to the device in embodiment 1, comprises the following steps:

[0054] Step A, according to the required concentration of the acid solution and the concentration of the acid solution in each acid tank, the required amount of each acid solution and water is set through the PLC control system;

[0055] Step B, send control signals to the electromagnetic valves and delivery pumps of the acid distribution device in sequence through the PLC control system, so that the original acid tank 13, the recovery acid tank 14, and the water inlet 12 are quantitatively mixed with the acid solution and water according to the predetermined flow rate / time. Transport to the online mixer 16 respectively from each pipeline, transport to the acid mixing tank 11 for standby after stirring and mixing;

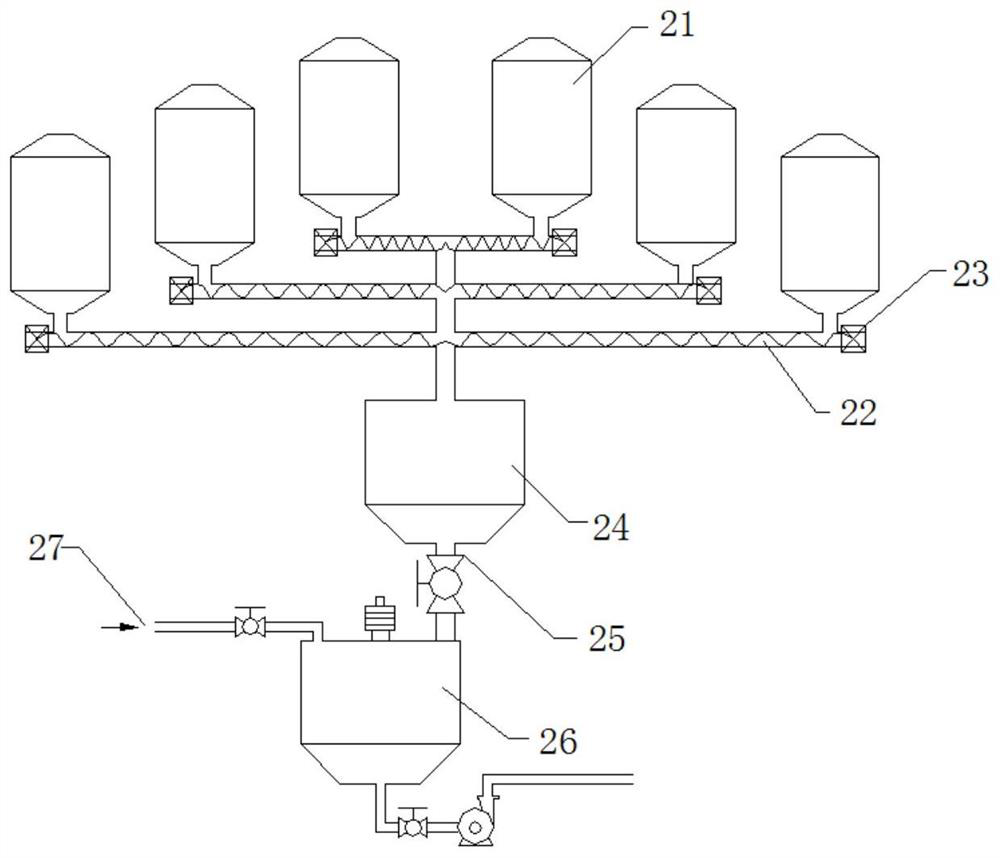

[0056] Step C, according to the batching ratio of bone powder of each particle si...

Embodiment 3

[0062] refer to figure 2 , an automatic acid distribution device for bone powder decalcification, comprising PLC control system, acid distribution tank 11 and water inlet 12, original acid tank 13, recovery acid tank 14, water inlet 12, original acid tank 13, recovery acid tank 14 through pipe After the pipelines meet at one place, they are connected to the acid distribution tank 11 through the online mixer 16 installed there, where the acid distribution tank 11, the original acid tank 13 and the recovery acid tank 14 are configured at their outlets There are solenoid valves and delivery pumps, flow meters 17 are installed at the outlets of the original acid tank 13 and the recovery acid tank 14, and double liquid level sensors are installed in the acid distribution tank 11, and the outlets are connected to the pickling tank 31 through pipelines.

[0063] The water inlet 12 is provided with a switch valve. After the pipeline for transporting water and the pipeline for transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com