Self-heating food packaging box

A food packaging box, packaging box technology, applied in the directions of packaging, packaging food, transportation and packaging, can solve the problems of easy crushing and extrusion deformation, many consumables, and large packaging volume, so as to improve the anti-deformation ability and ensure reliable packaging. The effect of reducing the size of the package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

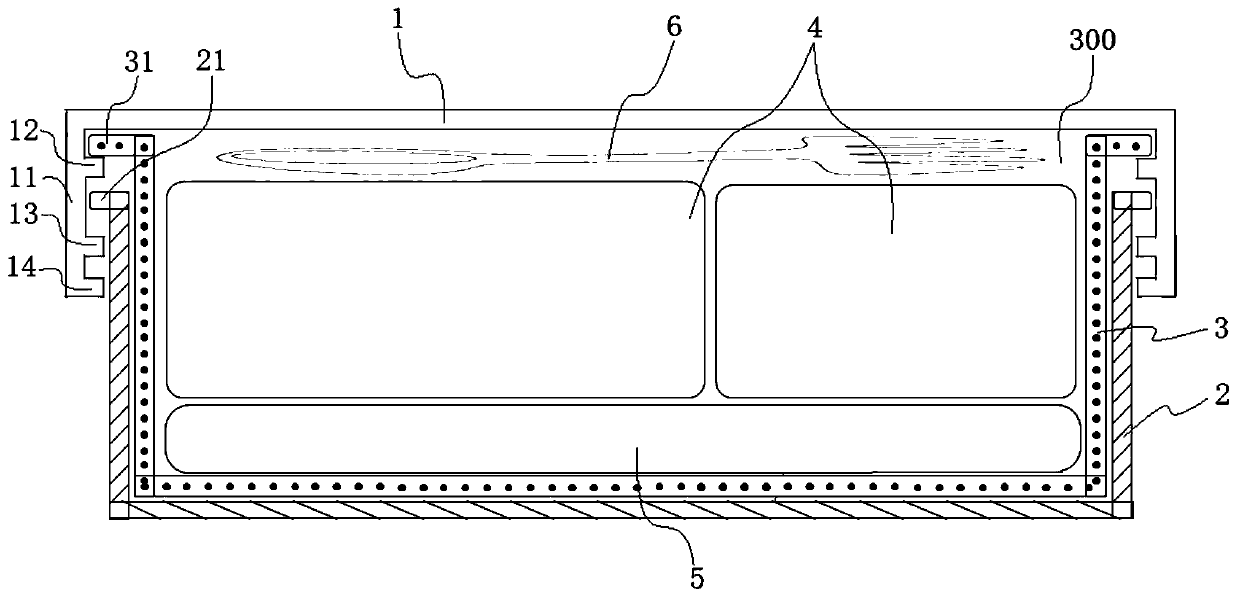

[0031] see figure 1 and figure 2 , the self-heating food packaging box in this embodiment is a preferred solution of the present invention, including three parts: a box cover 1, an outer box 2 and an inner box 3, and the inside of the packaging box is equipped with a food package 4, a heating package 5 and tableware 6. This packaging box is especially suitable for rice noodles, noodles and other staple foods that need to be mixed with soup, and it is also suitable for the packaging of rice and side dishes.

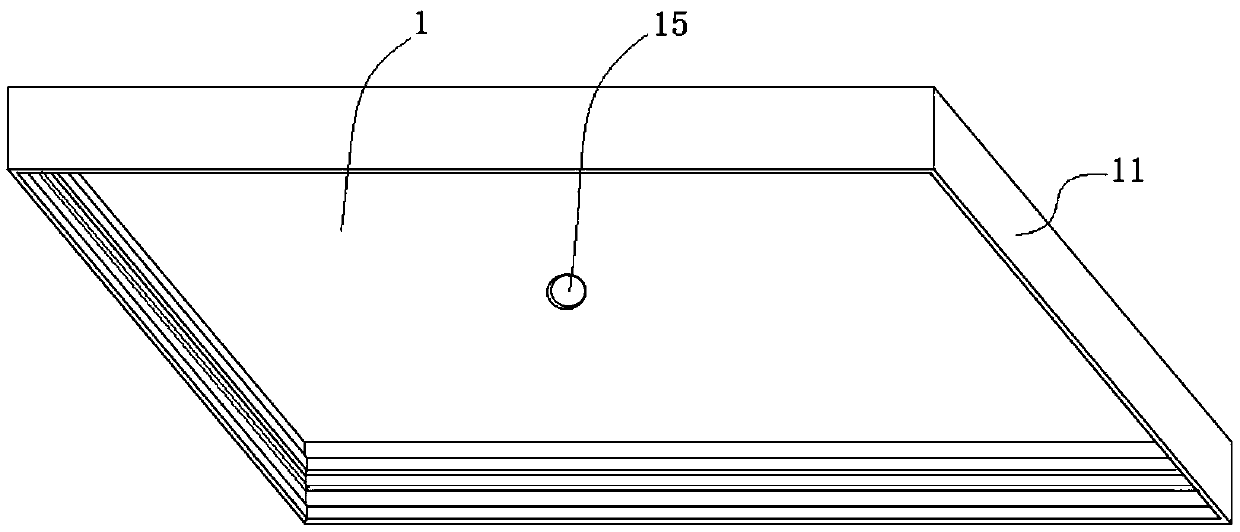

[0032] Specifically, the outer box 2 and the inner box 3 are square structures with matching sizes, the bottom square of the inner box 3 is slightly smaller than the bottom direction of the outer box 2, and both the outer box 2 and the inner box 3 are boxes with an open top surface. The inner box 3 is embedded in the outer box 2 from the top opening of the outer box 2 to form a movable box structure. The box cover 1 can be fastened on the outer box 2 and the inner box 3...

Embodiment 2

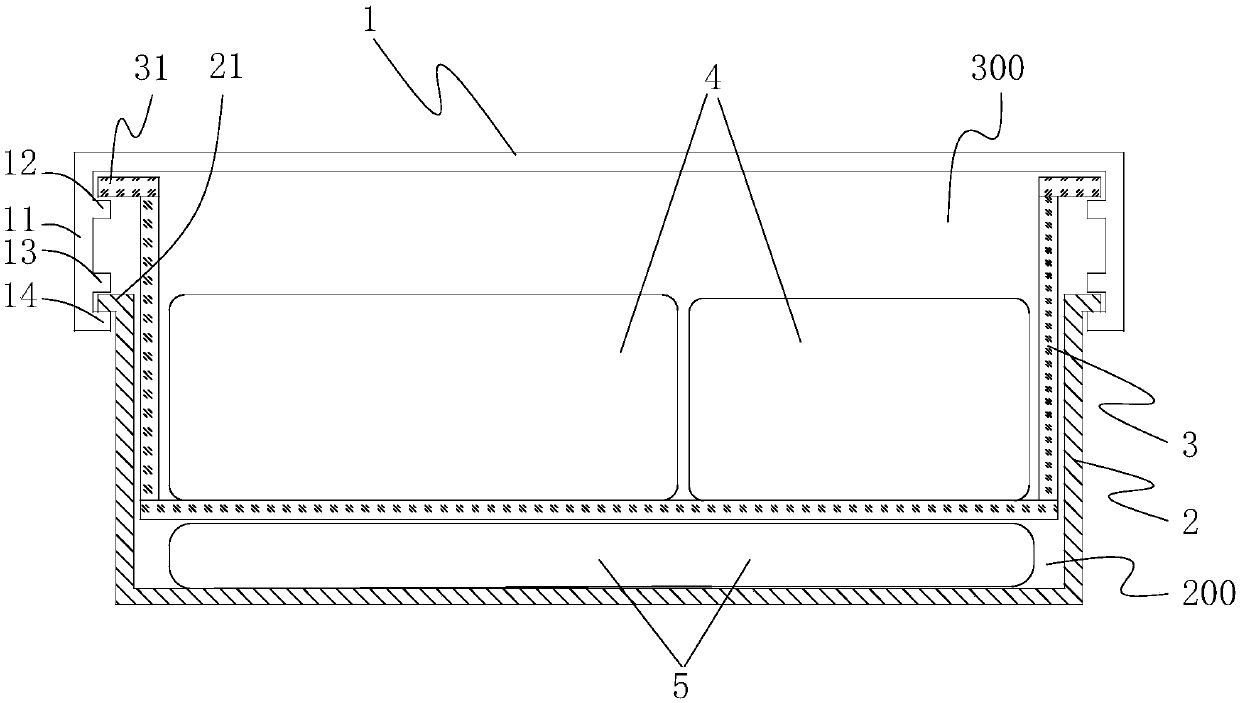

[0043] Such as Figure 6 and Figure 7 As shown, the self-heating food packaging box in this embodiment is another preferred solution of the present invention. This embodiment is suitable for self-heating rice packaging, which can be used to hold meals or soups, etc., to avoid the influence of meals in the same box. flavor.

[0044] Since the self-heating rice package generally packs staple food and side dishes or soup separately, the food package 4 in this embodiment includes a main ingredient package 41 and an ingredient package 42. On the basis of the first embodiment, the inner box 3 The inside of the box is provided with a vertical partition 33 to divide the inner box into two or more relatively independent spaces, such as Figure 8 As shown in , the main material package 41 and the ingredient package 42 are classified and placed in different packaging spaces. At the same time, the heating pack 5 is set as a plurality of sets of heating packs with one-to-one correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com