Belt conveyor tail cleaning device and method

A cleaning device and belt technology, which is applied to cleaning devices, transportation and packaging, conveyor objects, etc., can solve problems such as increasing labor intensity of workers, ineffective effects, and affecting production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

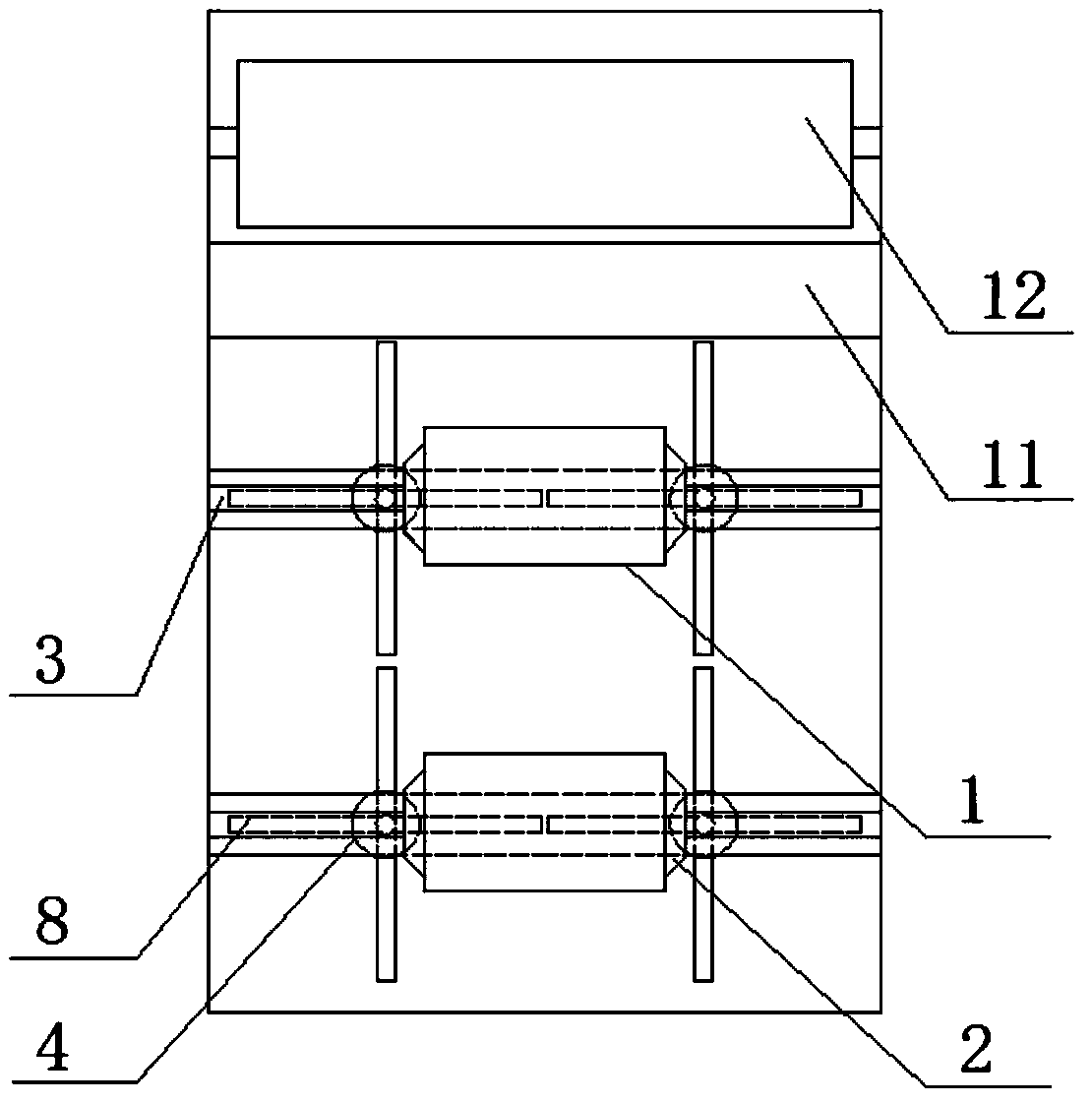

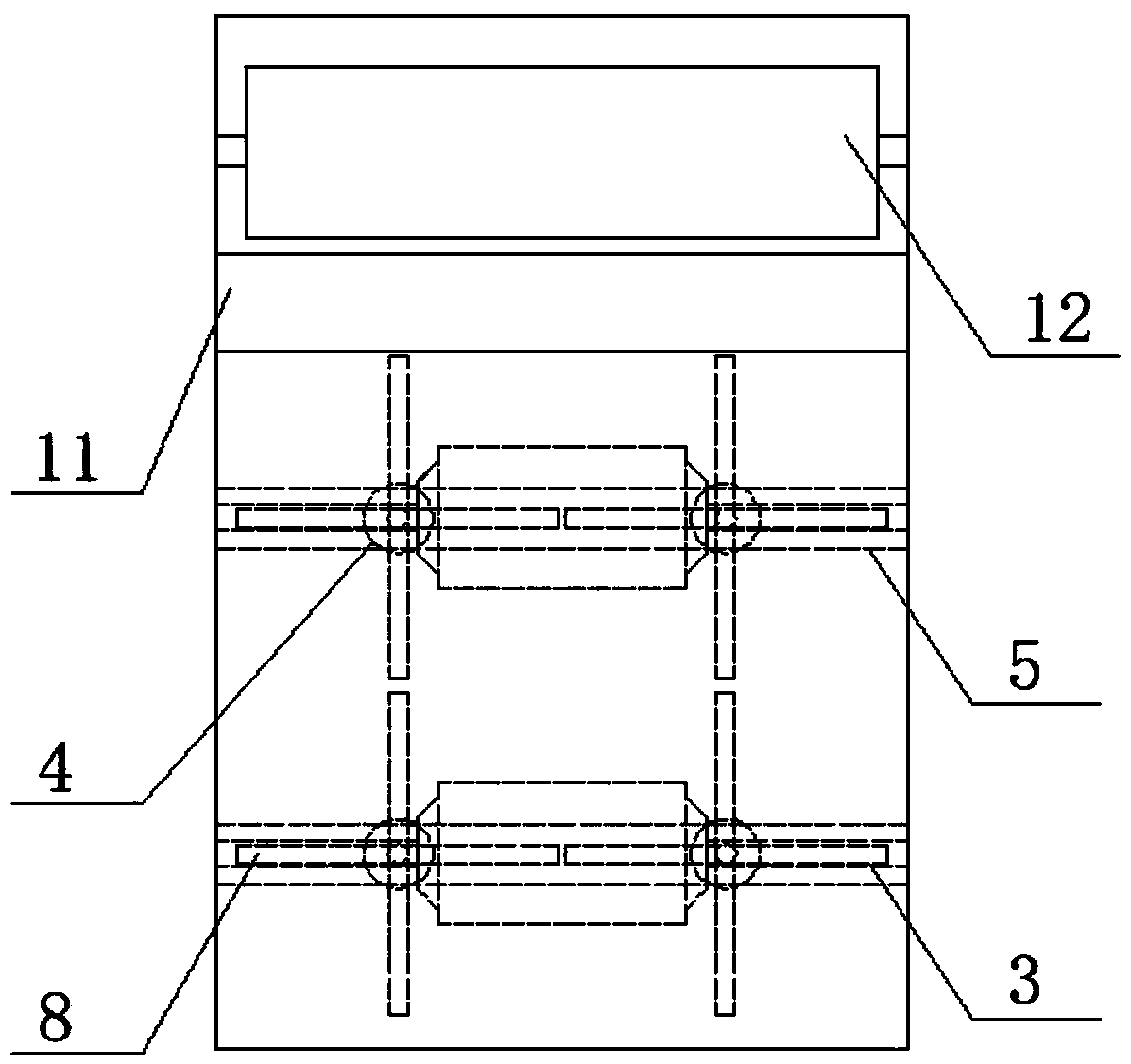

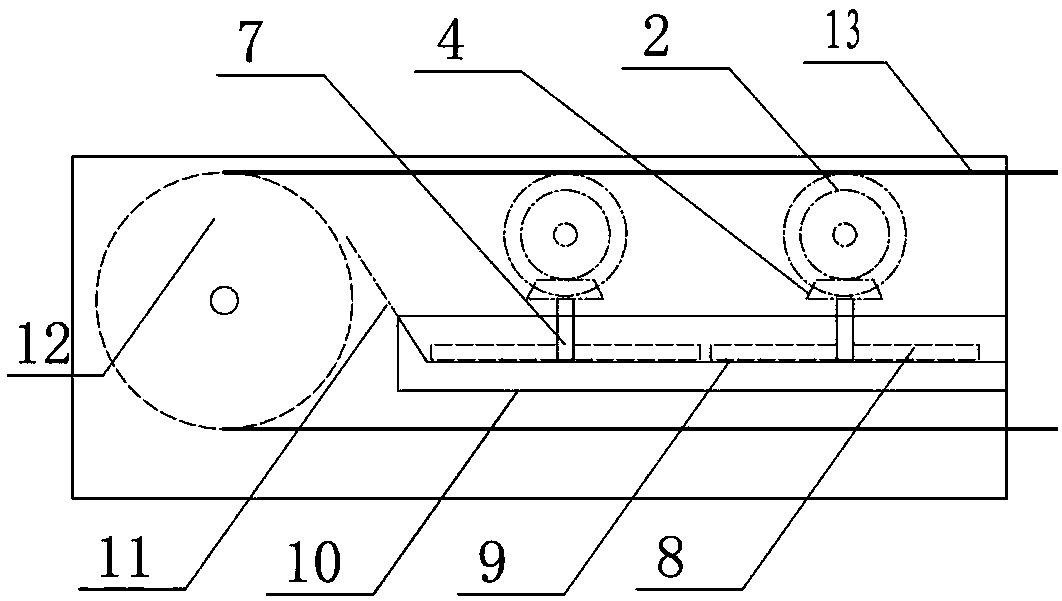

[0022] Embodiment 1: as Figure 1-Figure 7 As shown, a belt machine tail cleaning device includes a fixed frame 6 for placing a belt machine tail drum, a transmission system and a cleaning system. 13. The transmission system includes an idler 1 and a transmission mechanism. The idler 1 is rotatably connected to the fixed frame 6 through the rotating shaft 3 and keeps in contact with the belt 13 and is perpendicular to the conveying direction of the belt 13, and is connected to the cleaning sheet 8 through the transmission mechanism. The cleaning piece 8 is rotatably connected to the horizontal plate 5 on the fixed frame 6 through the vertical rotating shaft 7. In the fixed frame 6 and between the upper and lower sections of the belt 13 , material leakage windows 10 are arranged on both sides of the material receiving plate 9 .

[0023] Preferably, the transmission mechanism includes a driving bevel gear 2 and a driven bevel gear 4, the driving bevel gear 2 is fixedly connecte...

Embodiment 2

[0029] Embodiment 2: A cleaning method for a belt conveyor tail cleaning device. The method is as follows: during the operation of the equipment, the belt in contact with the idler drives the idler to rotate, and the idler drives the cleaning piece to connect the material plate through the driving and driven bevel gears. Cleaning, the material on the receiving plate is cleaned out through the leakage windows on both sides of the receiving plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com