A stable mosi in high temperature air 2 -sio 2 Composite photothermal coating and preparation method thereof

A high-temperature air and compound technology, applied in coatings, radiation-absorbing coatings, fire-retardant coatings, etc., can solve problems such as the need to improve high-temperature stability, unsuitable for long-term stable use, and complex equipment required for production. Production, suitable for large-scale production, good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

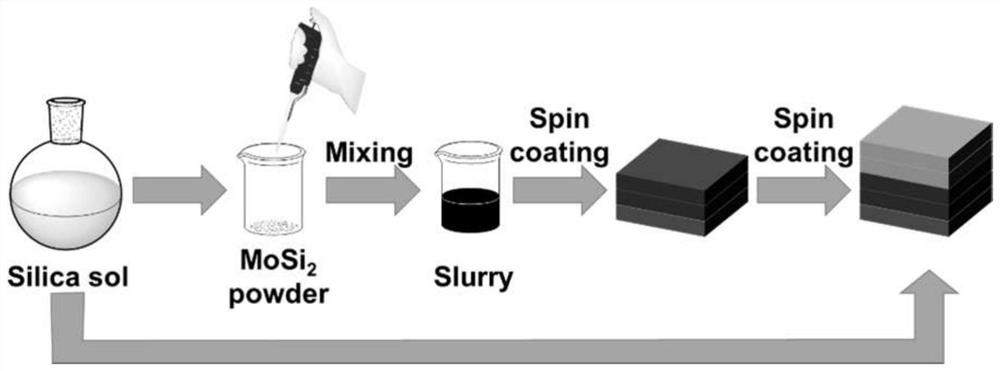

[0033] refer to figure 1 MoSi shown 2 -SiO 2 Schematic diagram of the composite coating preparation process,

[0034] A certain amount of molybdenum powder and silicon powder are subjected to high-energy ball milling reaction according to the molar ratio of Mo:Si=1:3, and the process is carried out for 10 hours to obtain MoSi 2 powder.

[0035] Silica sol is prepared by hydrolysis and polycondensation of tetraethyl silicate (TEOS). Tetraethylsilicate (TEOS), methyltriethoxysilane (MTES), ethanol, deionized water and acetic acid were respectively added to 100ml round in the bottom flask. Magnetically stirred at room temperature for 24 hours to obtain a transparent silica sol.

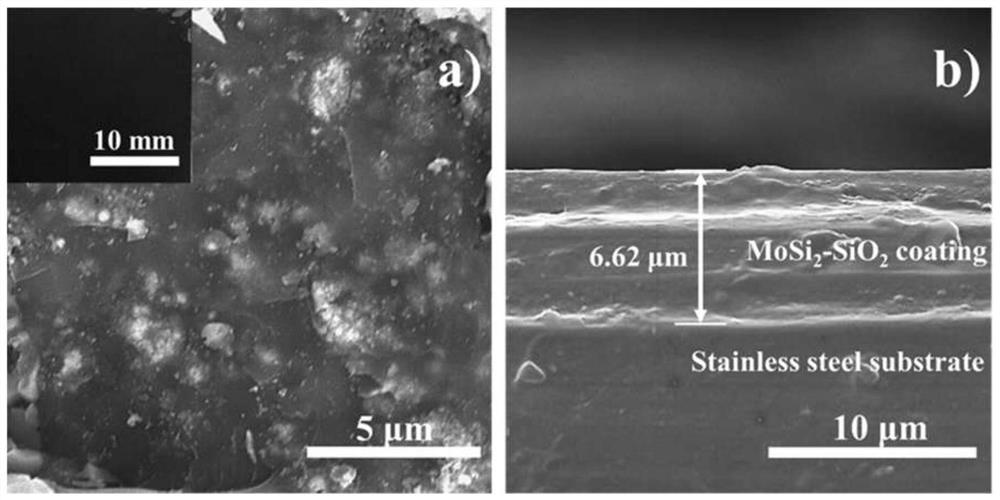

[0036] The prepared silica sol and MoSi 2 Powder mixing (1ml silica sol with 0.1g MoSi 2 powder), spin-coat on stainless steel (SUS-304) after forming a black suspension, and dry in an oven at 80°C for half an hour. This step was repeated twice. Then, the transparent silica sol (volume 1ml) was...

Embodiment 2

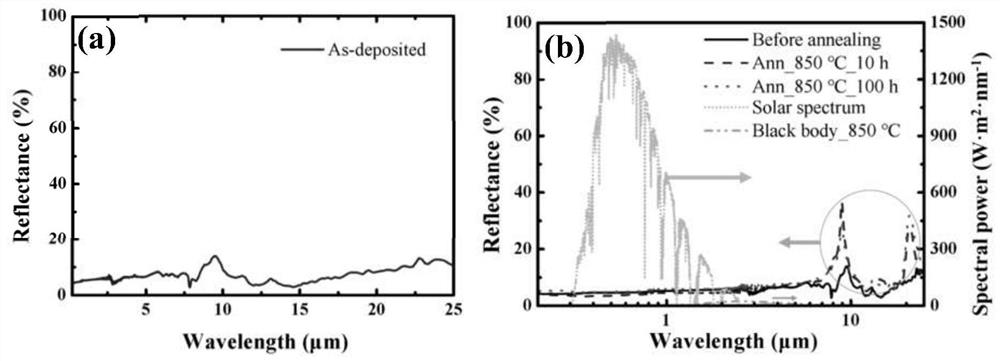

[0039] 0.1g MoSi2 powder mixes 2ml silica sol, the coating absorption that adopts the exact same method of embodiment 1 to obtain is lower, and reflection spectrum sees Figure 4 "---"curve.

Embodiment 3

[0041] 0.2g MoSi 2 The powder is mixed with 1ml of silica sol, and the coating obtained by the same method as in Example 1 has low absorption, and the reflection spectrum is shown in Figure 4 "……"curve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com