Construction method of cast-in-place reinforced concrete guardrail

A technology of reinforced concrete and construction methods, applied in the field of bridge engineering, to achieve good uniformity, reduce difficulty, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Reinforcement cage binding and welding construction technical requirements, on-site hoisting construction technical requirements, concrete mix ratio design and pouring construction technical requirements, formwork preparation and installation construction technical requirements, etc., will not be described in detail in this embodiment, and the implementation of the method involved in the present invention will be focused on Way.

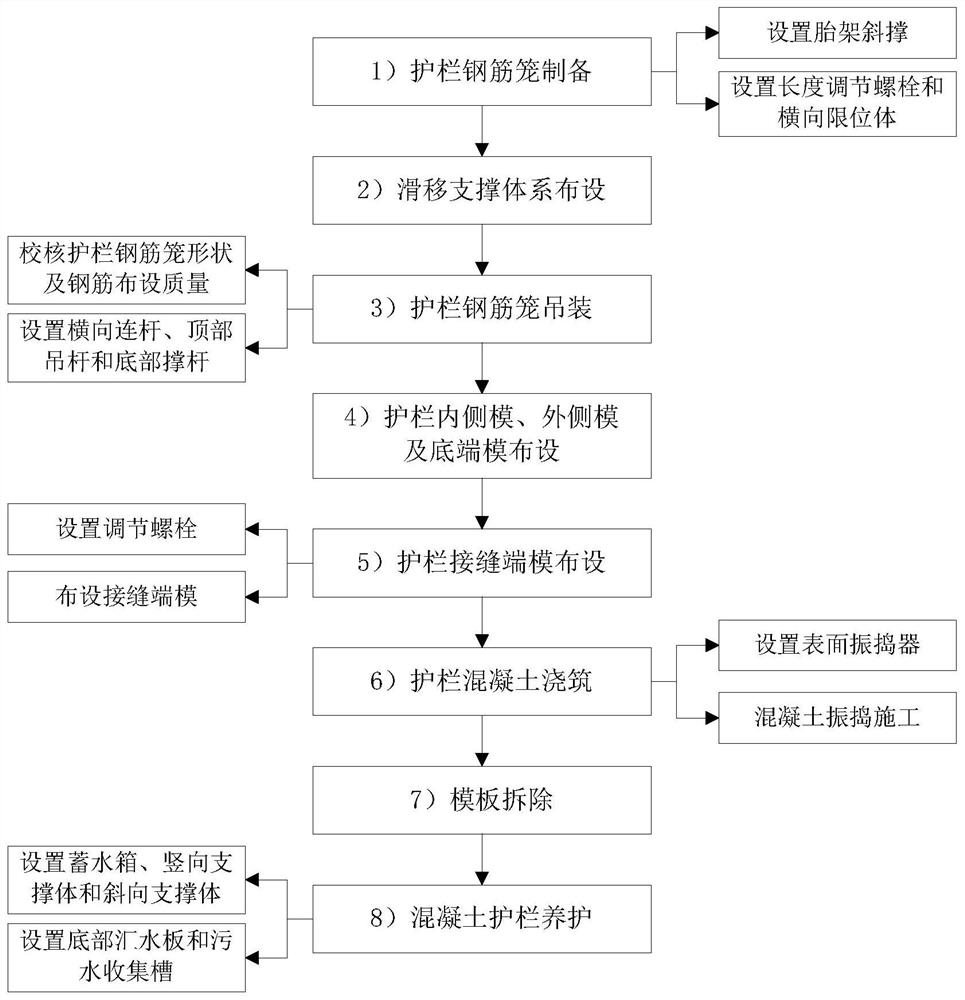

[0041] figure 1 It is the construction flowchart of cast-in-place reinforced concrete guardrail of the present invention, with reference to figure 1 As shown, the construction method of cast-in-place reinforced concrete guardrail includes the following construction steps:

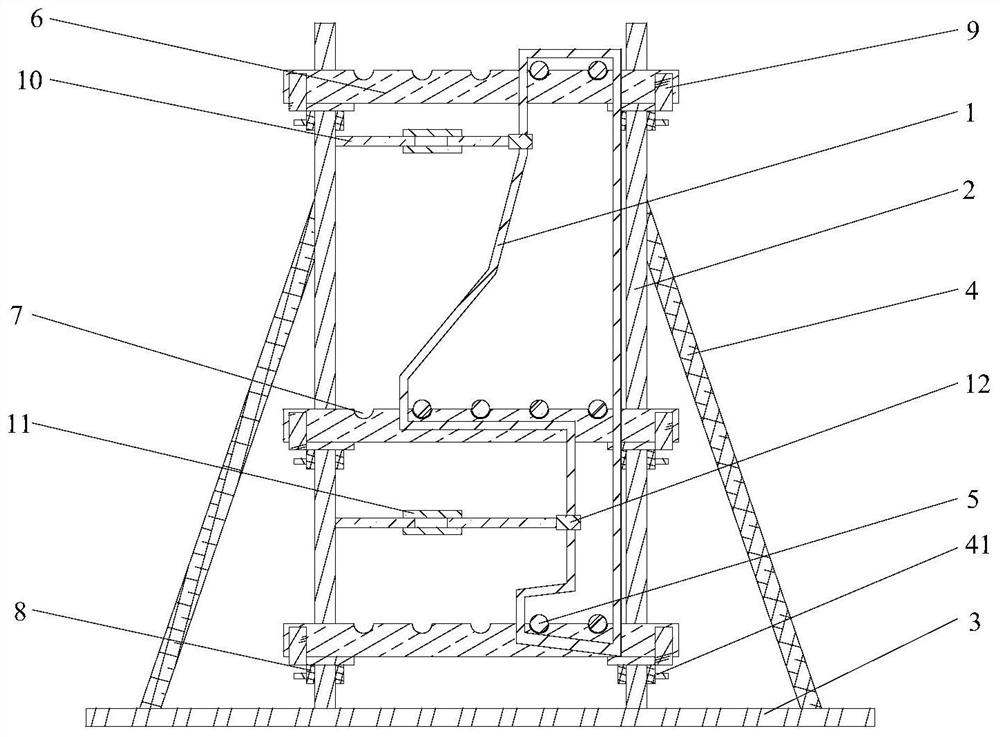

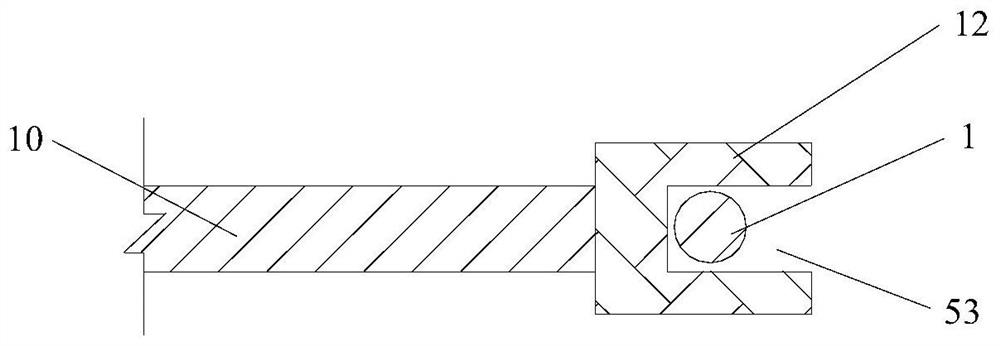

[0042] 1) Preparation of the guardrail reinforcement cage 1: make the bottom of the side brace 2 vertically connected to the tire frame bottom plate 3, and set the tire frame diagonal brace 4 between the side brace 2 and the tire frame bottom plate 3; according to the guar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com