T-shaped steel reinforced welding connection joint

A technology for strengthening welding and connecting nodes, which is applied to building types, building components, and earthquake resistance. It can solve problems such as heavy inspection workload, poor earthquake resistance, and fatigue of steel structures, and achieve high steel utilization and good self-resetting ability. , The effect of improving energy consumption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

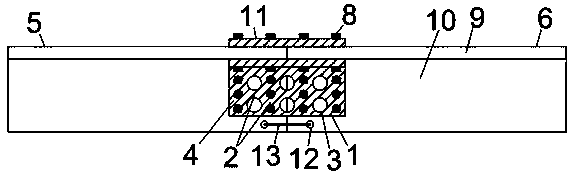

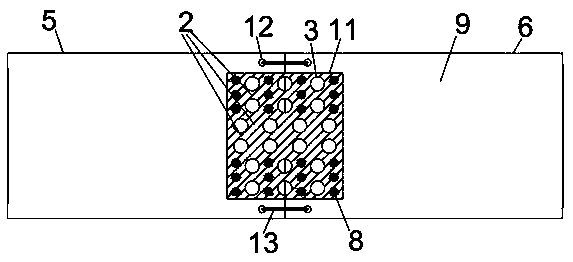

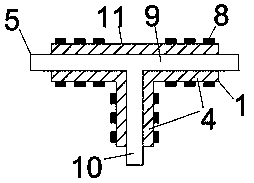

[0026] Embodiment: a kind of T-shaped steel reinforced welded connection node, such as Figure 1~Figure 12 The shown includes right-angle energy dissipation connecting steel plate 1, energy dissipation rib 2, inner round hole 3, separate energy dissipation connecting plate 4, T-shaped steel A5, T-shaped steel B6, lead pin hole 7, lead pin 8, horizontal steel plate 9, vertical direction steel plate 10, main energy dissipation connecting steel plate 11, binding hole 12 and shape memory alloy wire 13;

[0027] In the structure of reinforced welded connection joints of T-shaped steel, welded connection is used for reinforcement at the contact of T-shaped steel A5 and T-shaped steel B6. Consisting of a transverse steel plate 9 and a vertical steel plate 10, a number of lead pin holes 7 and binding holes 12 are respectively set on the transverse steel plate 9 at the connection end of T-shaped steel A5 and T-shaped steel B6, and the binding holes 12 are set on the upper and lower sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com