Multi-directional unloading system and construction method for assembling steel corridor by same

A technology for steel corridors and corridors, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of high consumption of materials, redundant waste, complicated construction, etc., achieving low cost, avoiding collapse, and short construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

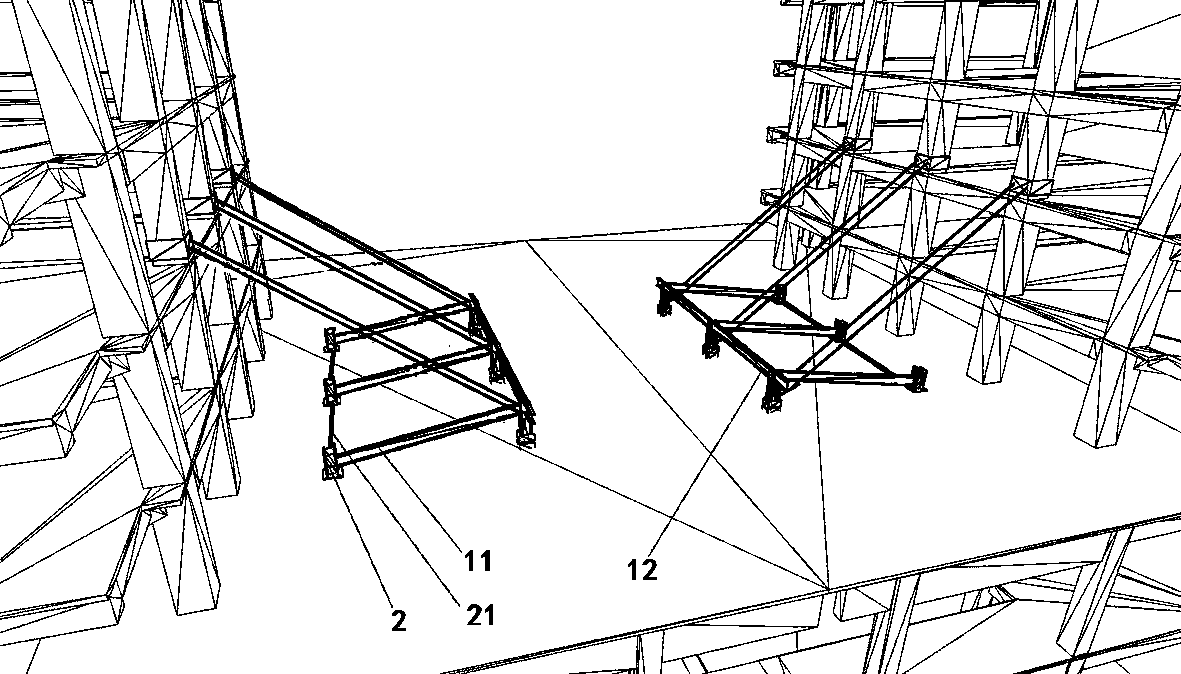

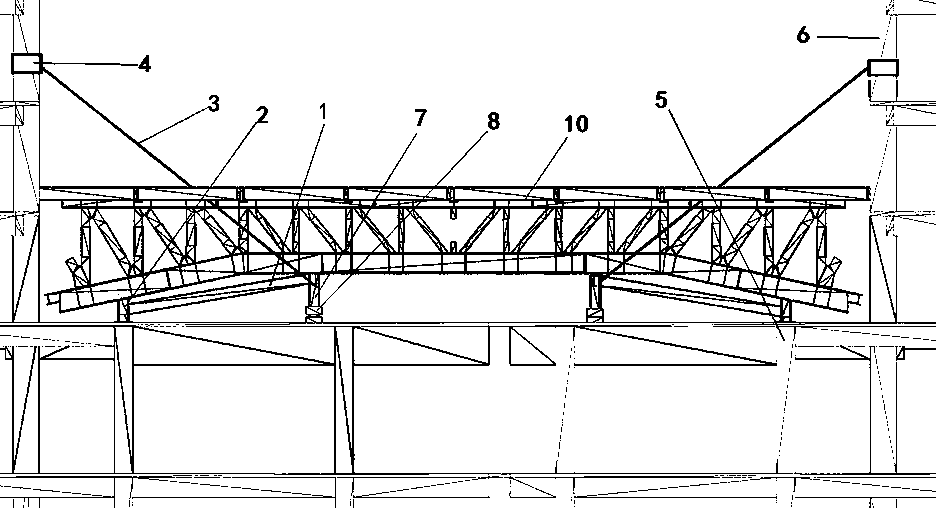

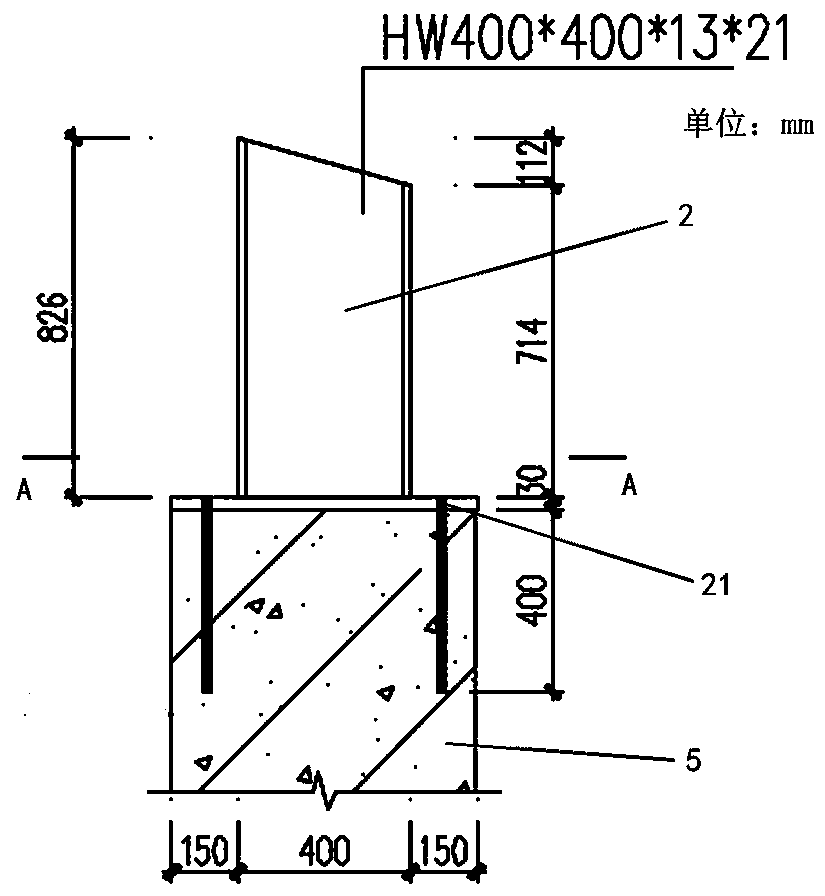

[0052] Such as Figure 1 to Figure 9 As shown, this embodiment is a multi-directional unloading system and a construction method for assembling steel corridors using the system. Among them, the unloading system of this embodiment is applied in the area between the tall buildings on both sides, and the corridors of the tall buildings on both sides are assembled on the top of the podium; the assembled area is the top of the podium (elevation 23.000m). The span of the corridor of the steel structure is about 32m, and the main truss is an I-shaped member with a cross-section of 600×800×40mm. The lateral support and web joints are all high-strength bolt hinge points. Considering the actual conditions on site, it is necessary to choose a reasonable segmentation and assembly scheme to achieve economical rationality, safety and reliability, and technical feas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com