Liquid level sensor calibration device and calibration method

A liquid level sensor and calibration device technology, applied in the direction of testing/calibration devices, measuring devices, instruments, etc., can solve problems such as equipment misoperation, unreliability, and low work efficiency, so as to avoid equipment misoperation or damage, reduce The risk of equipment damage and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

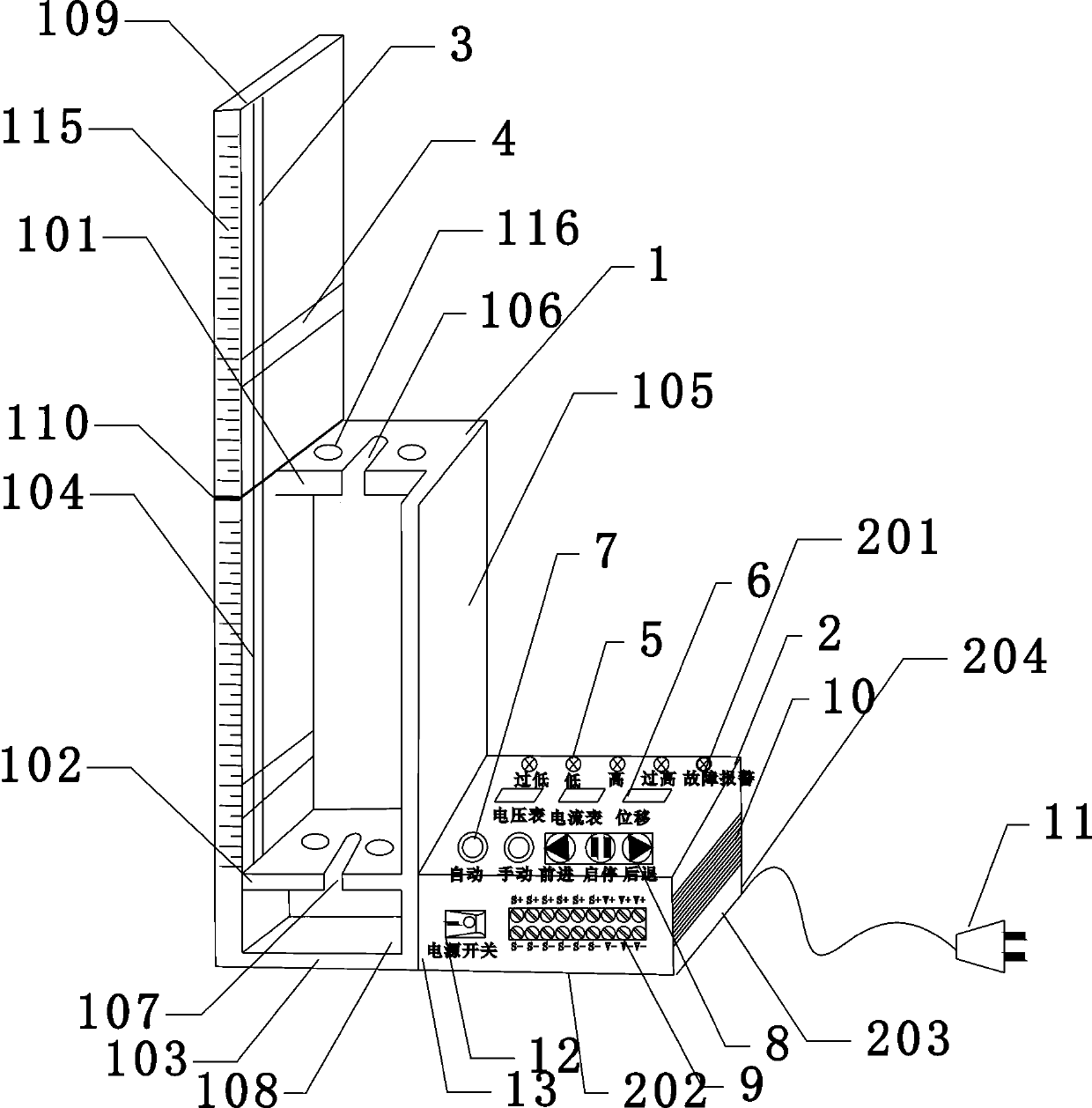

[0073] This embodiment takes the top-mounted liquid level sensor with a floating ball to verify the analog and switch values as an example to explain the specific working principle and usage method. The working principle of the top-mounted magnetic float level gauge: it uses the float assembly as the measuring element, and is made according to the principle of buoyancy and magnetic coupling. When the liquid level in the container changes up and down, it drives the floating ball, and moves up and down through the permanent magnet steel on the upper end of the connecting rod connected to it, and makes the turning column in the display turn over through magnetic coupling. When the liquid level rises, the turning column turns from white to red, and when the liquid level drops, the turning column turns from red to white. The red and white boundary is the actual height of the medium liquid level in the container, so as to realize the automatic tracking and display of the liquid lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com