Servo Control Method Based on Synchronous Processing of Clock Excitation Feedback

A technology of servo control and synchronous processing, applied in the direction of program control, digital control, electrical program control, etc., can solve the problems of out-of-synchronization of feedback and poor control effect, so as to save hardware resources, avoid poor effect, and reduce design cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

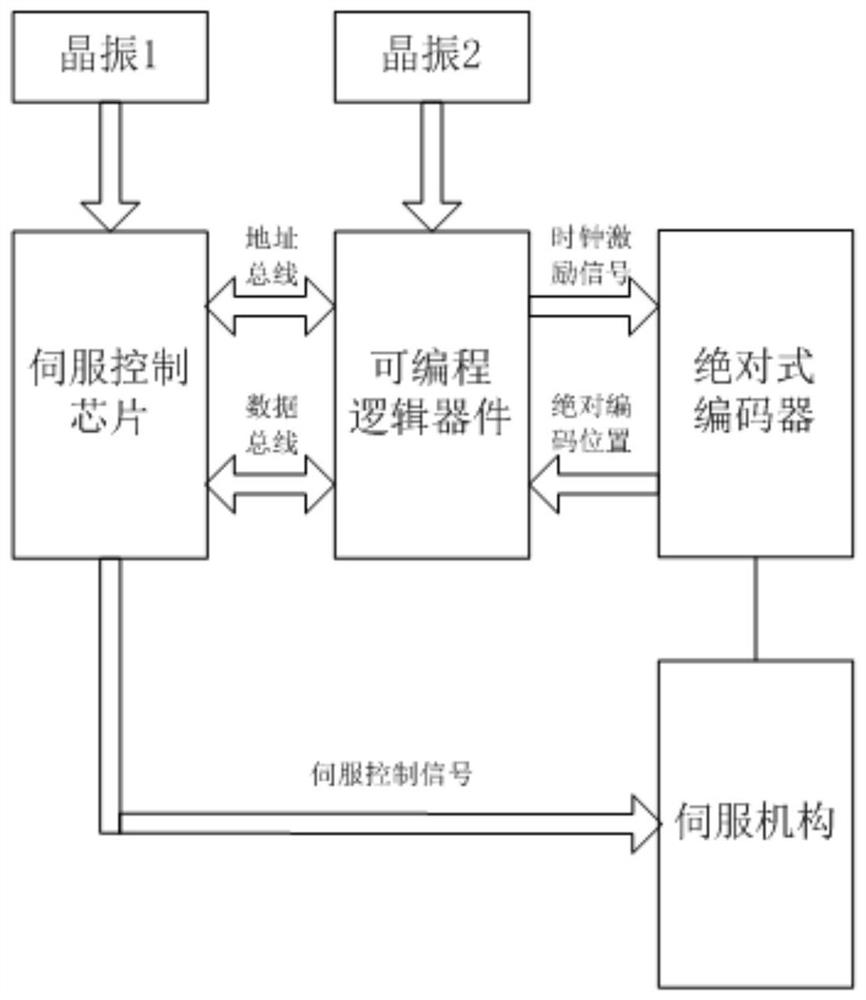

[0021] After the programmable logic device of the servo control system collects a beat of absolute coded position data, it actively sends a synchronization signal to the servo control chip. The servo control chip uses the synchronization signal as an external interrupt input source to trigger an external interrupt, and the interrupt receives the programmable logic The current position data collected by the device is used for closed-loop servo control, which can avoid the problem of poor control effect caused by asynchronous feedback based on clock excitation.

[0022] This method sends a synchronous signal in real time through the programmable logic device to realize the synchronous acquisition of absolute coded position data by the servo control chip. The functional block diagram of the servo control system is shown in Figure 4 shown.

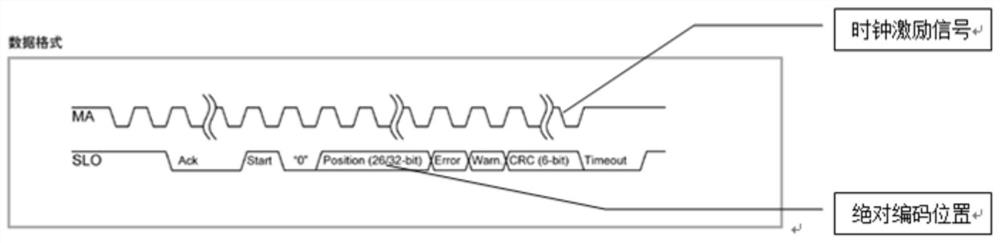

[0023] The programmable logic device of the closed-loop servo system sends a clock excitation signal of a certain frequency according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com