Single-stage AC-DC multi-output electrolytic-capacitor-free high-power LED driving power source

An AC-DC, LED drive technology, applied in the direction of electric light source, electrical components, electroluminescent light source, etc., can solve the problems of low DC bus voltage and small number of devices, so as to improve power factor, reduce cost and volume, avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

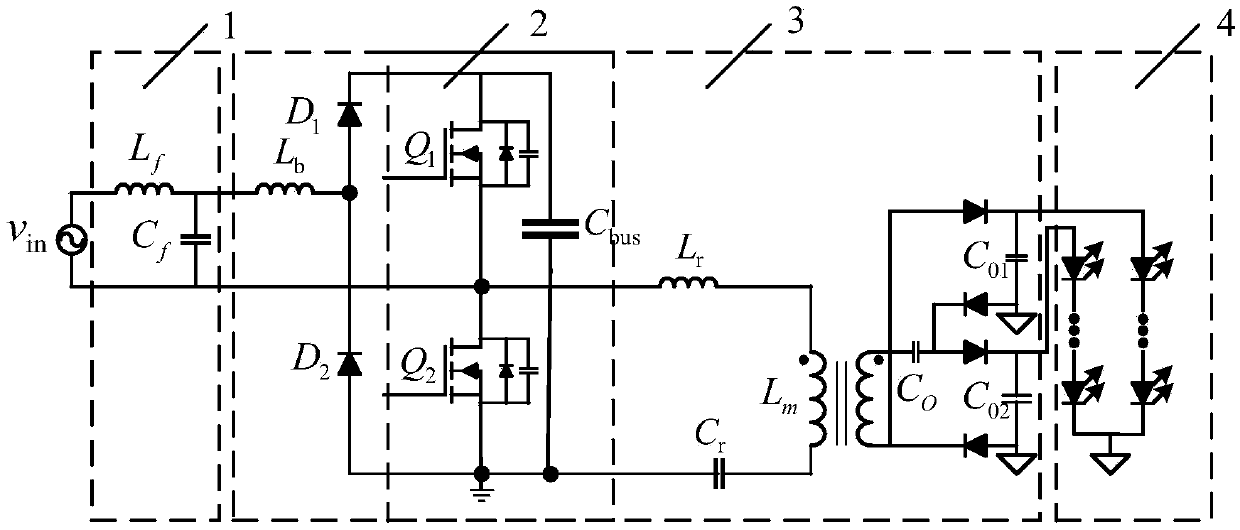

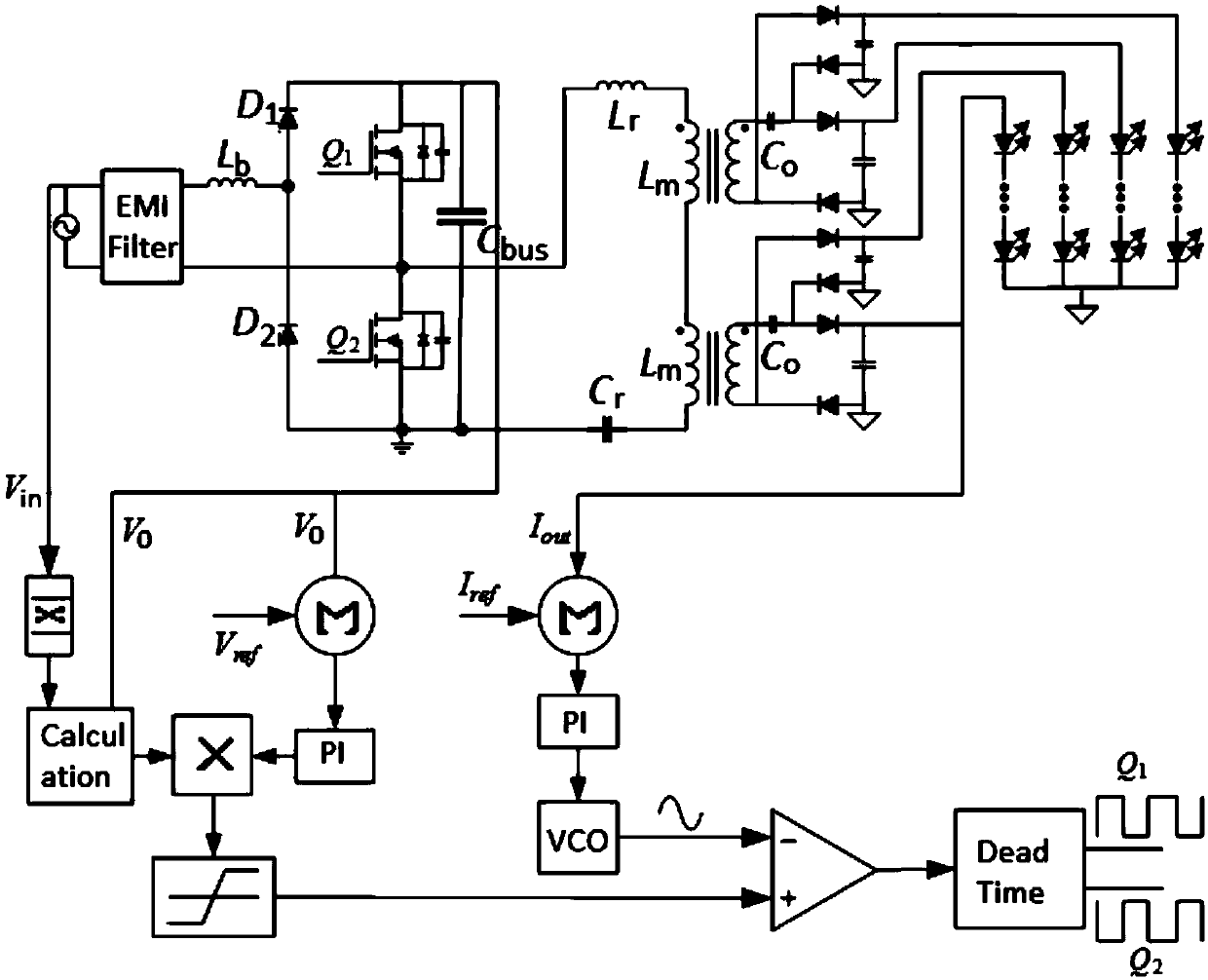

[0009] Such as figure 1 The topological structure diagram of single-stage AC-DC multi-output high-power LED drive circuit without electrolytic capacitors is shown, including input filter circuit 1, bridgeless Boost PFC circuit 2, half-bridge LLC resonant circuit 3 and LED load 4; AC power supply V in The input end is connected to the LC filter circuit, and the output of the LC filter circuit is connected to the bridgeless Boost power factor correction circuit; the bridgeless Boost power factor correction circuit 2 is connected to the half-bridge LLC resonant circuit 3, and the two circuits share two switch tubes; the half-bridge LLC The output of the resonant circuit is connected to the LED load; the single-stage integrated structure of two switching tubes is shared by the bridgeless Boost PFC circuit and the half-bridge LLC resonant conversion circuit to reduce the number of devices, reduce device power loss, and improve overall operating efficiency; bridgeless Boost PFC The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com