Acetanilide synthesis special reactor

A technology of acetanilide and reactor, which is applied in the field of special reactors for acetanilide synthesis, to achieve the effects of reduced gas phase resistance, increased gas velocity at flooding point, and reduced power equipment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

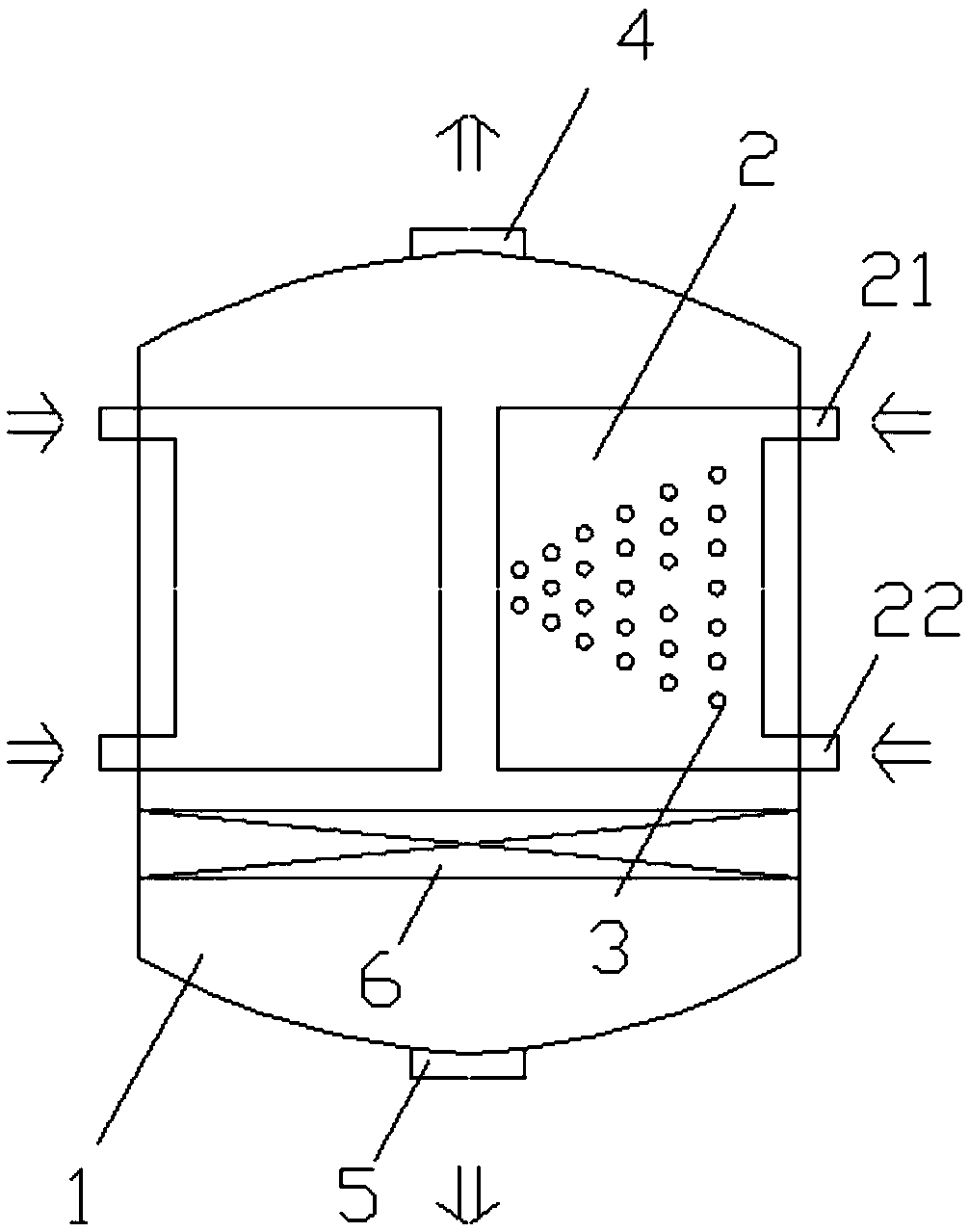

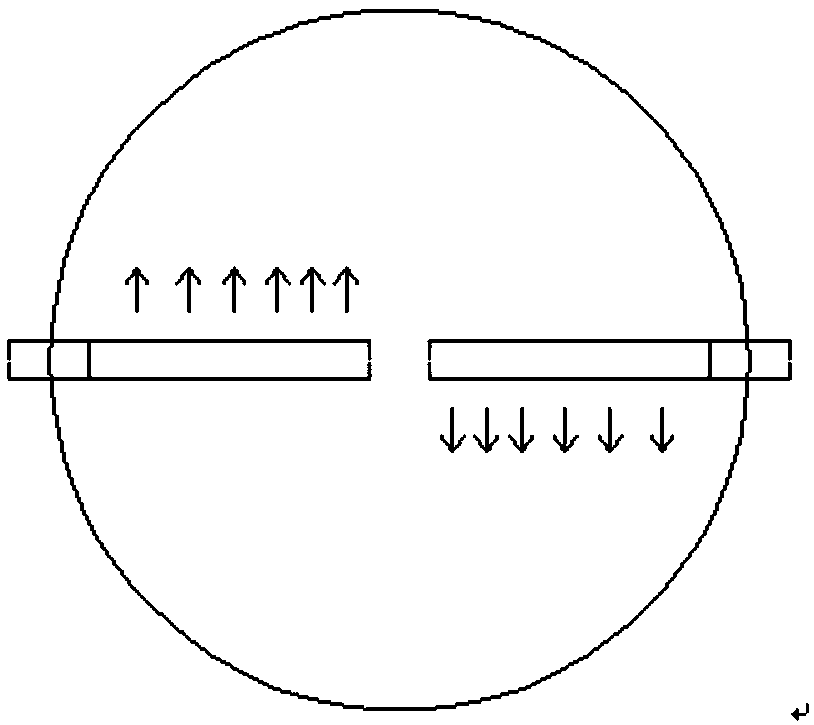

[0020] Such as figure 1 Shown, the present invention comprises reactor body 1, and reactor body 1 is made up of reactor top, bottom and sidewall, and the top of described reactor body 1 is provided with gas outlet 4; The bottom is provided with a liquid outlet 5; the lower part of the reactor body 1 is provided with a packing area; the middle and upper part of the reactor body 1 is provided with two hollow feed plates 2, and the gap between the hollow feed plate 2 and the outer wall of the reactor Space for material flow is reserved between them; the hollow feed plate 2 is vertically arranged, the upper part is provided with an air inlet 21, and the lower part is provided with a liquid inlet 22, and the inside of the hollow feed plate 2 is a hollow cavity , which can be used for gas and liquid mixing; on both sides of the middle part of the hollow feed plate 2, one side is a non-porous flat plate, and the other side is provided with a number of small holes which can be atomize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com