Pipeline interface sealing device and preparation method thereof

A technology of sealing device and pipe interface, applied in the direction of engine sealing, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of complex processing technology, increased compression degree, large rebound resistance, etc., to simplify the process, extend the Service life and the effect of reducing installation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]The value ranges of R1, R2, R3 and the included angle α in this embodiment are different according to the size and size of the sealing device, and the specific calculated values are different, which is not specifically limited in this embodiment.

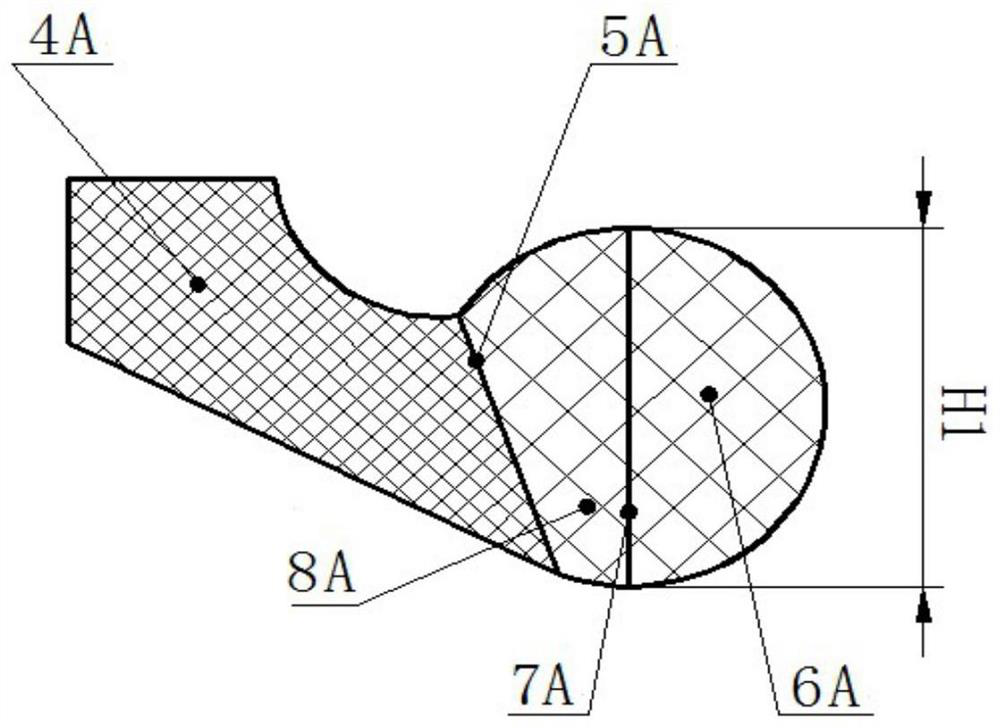

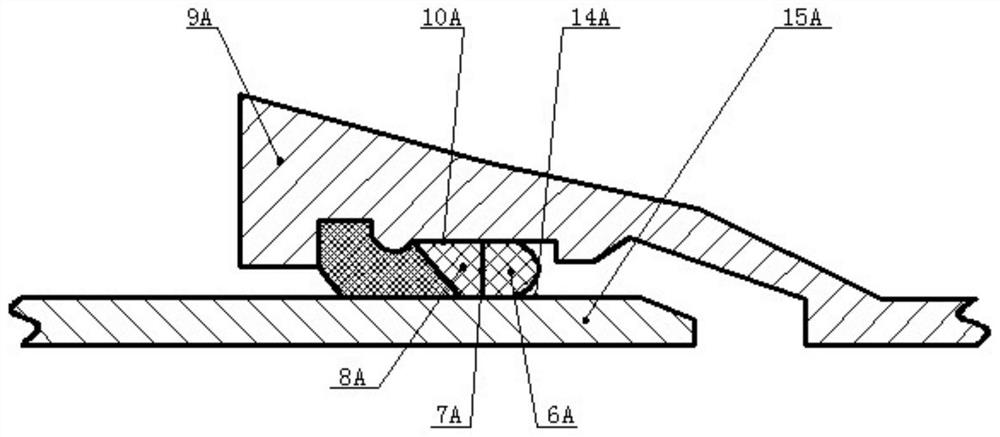

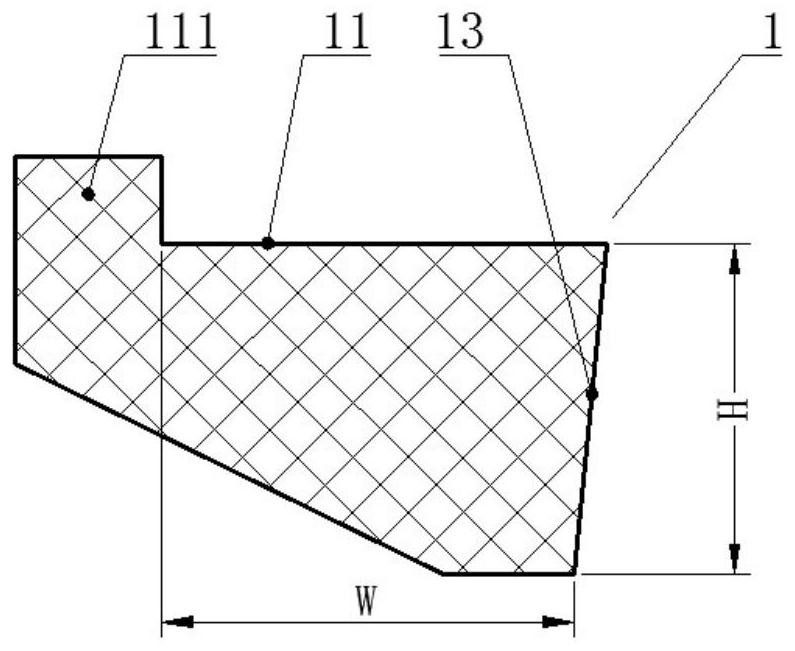

[0032] Such as Figure 3 to Figure 5 As shown, the pipe interface sealing device equipped with a sealing rubber ring in this embodiment includes a pipe socket 2, a pipe socket 3 and a sealing rubber ring 1 for sealing when the two are connected. The sealing rubber ring 1 is integrally formed and has the same hardness throughout. The pipe socket 3 is inserted into the pipe socket 2, and the sealing rubber ring 1 between the sockets is compressed to form a sealing system. The medium contact surface 13 of the sealing rubber ring 1 is an inclined plane to realize the sealing of the interface. The outer surface 11 of the sealing rubber ring 1 is a plane, and one end of the plane is provided with an upward raised portion 111, and...

Embodiment 2

[0036] Such as Figure 6 , Figure 7 As shown, the difference between this embodiment and the first embodiment is that the medium contact surface 13 of the sealing rubber ring 1 is a corrugated surface. The pipe socket 3 is inserted into the pipe socket 2 installed with the sealing rubber ring 1, and the medium contact surface 13 of the sealing rubber ring 1 contacting the fluid in the pipe is extruded into a concave curved surface, realizing a good sealing of the interface.

Embodiment 3

[0038] Such as Figure 3 to Figure 7 As shown, the present embodiment adopts the following steps to prepare the pipeline interface sealing device:

[0039] 1) Using materials with the same hardness, prepare a whole piece of colloid to form the sealing rubber ring 1. According to the ratio range of R1 and R2, an upward raised portion 111 is formed on the outer surface 11 of the sealing rubber ring 1, and the inner surface 12 Form a curved surface connected by a conical surface 121 and a cylindrical surface 122, and the medium contact surface 13 forms an inclined surface or a wave surface;

[0040] 2) Process the shape of each part on the pipe socket 2 that cooperates with the sealing rubber ring 1, according to the ratio range of R3 and the angle range between the inner tapered surface 23 of the pipe socket 2 and the axial direction of the pipe socket 2, in A rubber ring fixing groove 21 and an inner sealing surface 22 matching the shape of the raised portion 111 are processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com