Plant polyphenol based preparation method of core-shell structural nano-silver antibacterial material

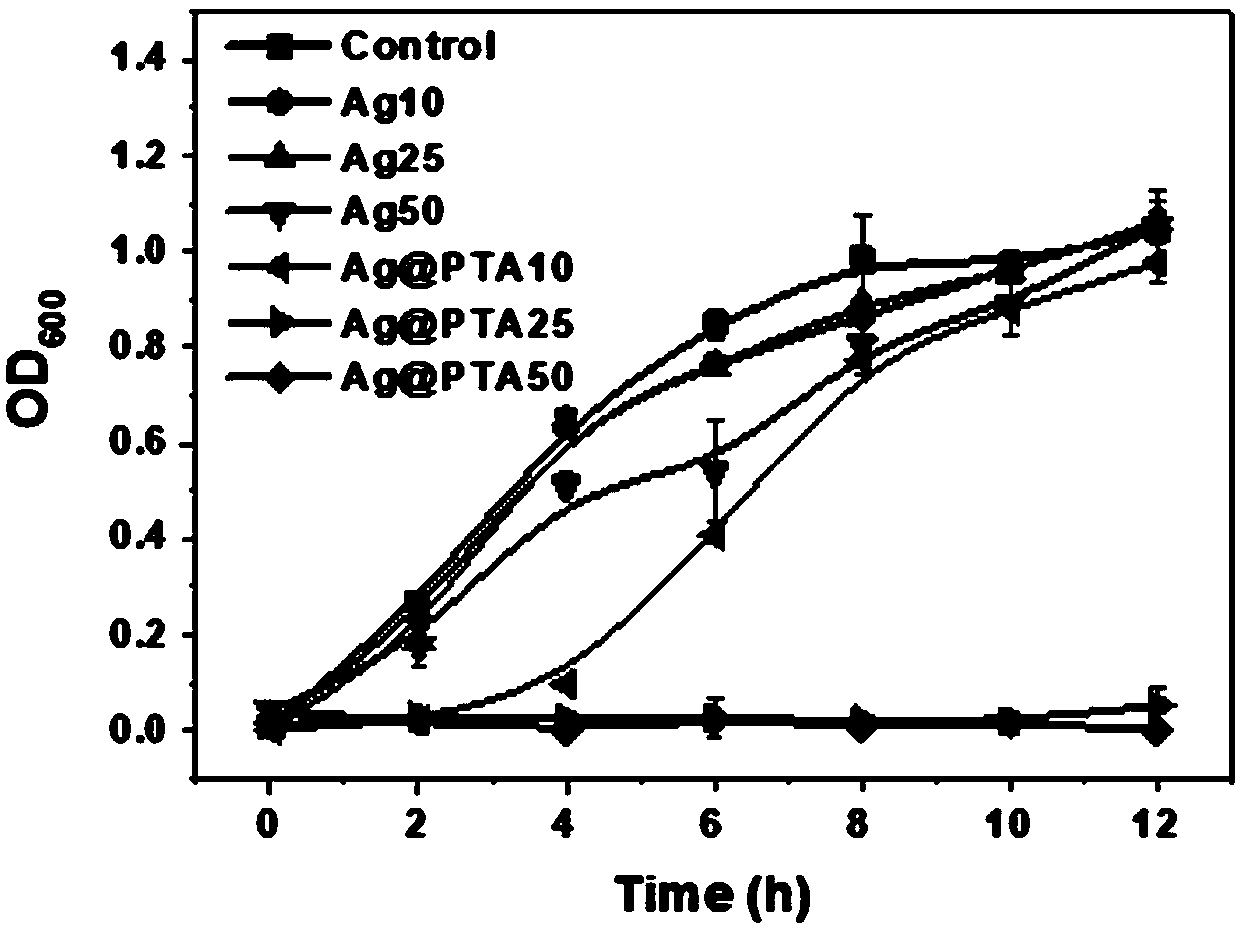

A nano-silver antibacterial, core-shell structure technology, applied in the fields of botanical equipment and methods, chemicals for biological control, plant growth regulators, etc., can solve the problem of hindering the formation of tannic acid-Ag complex structures Core-shell structure, low solid content of nano-silver, etc., achieve the effects of green raw materials, large-scale production, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a core-shell structure nano-silver antibacterial material based on plant polyphenols, specifically adopting the following steps:

[0037] 1) The AgNO 3 Dissolve in phosphate buffer at pH=7, then dissolve tannic acid in ultrapure water;

[0038] 2) Add the tannic acid solution obtained in step 1) dropwise to the AgNO obtained in step 1) 3 solution, at a room temperature of 25°C, oscillate with a mechanical oscillator for 20 minutes, centrifuge the reaction solution, collect the precipitate and dissolve it in ultrapure water to obtain the product, wherein the tannic acid and AgNO 3 The mass ratio of is 1:10, and the concentration of the phosphate buffer is 2mM.

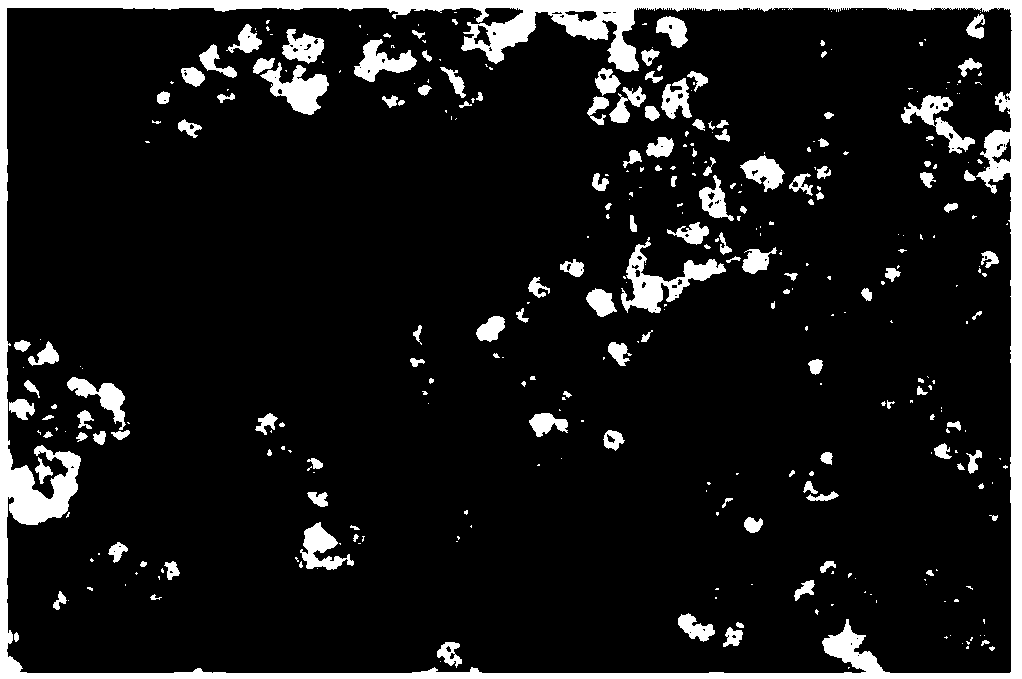

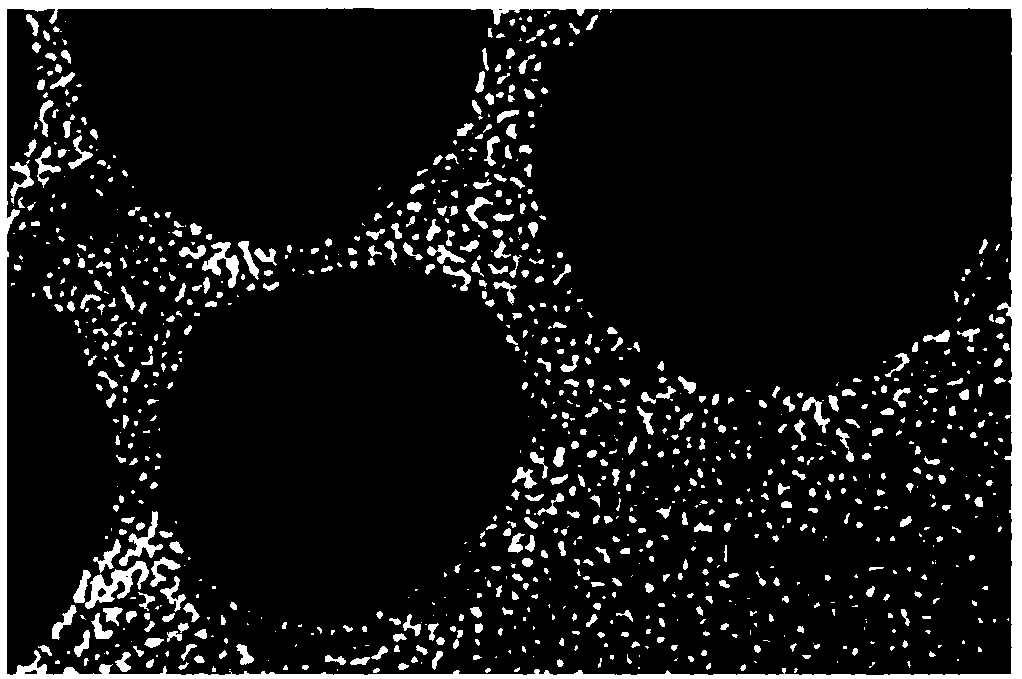

[0039] 3) Centrifuge and precipitate the reaction solution after mechanical vibration in step 2), collect the precipitate and dissolve it in ultrapure water to obtain the product core-shell structure nano-silver (Ag@PTA), and perform SEM and TEM on the prepared nano-silver shooting, such...

Embodiment 2

[0041] A method for preparing a core-shell structure nano-silver antibacterial material based on plant polyphenols, using the following steps:

[0042] 1) The AgNO 3 Dissolve in phosphate buffer at pH=8, then dissolve tannic acid in ultrapure water;

[0043] 2) Add the tannic acid solution obtained in step 1) dropwise to the AgNO obtained in step 1) 3 solution, at room temperature, vibrate with a mechanical oscillator for 12 minutes, centrifuge the reaction solution, collect the precipitate and dissolve it in ultrapure water to obtain the product, wherein the tannic acid and AgNO 3 The mass ratio of is 1:55, and the concentration of the phosphate buffer is 11 mM.

[0044] 3) Centrifuge and precipitate the reaction solution after mechanical vibration in step 2), collect the precipitate and dissolve it in ultrapure water to obtain the product core-shell structure nano-silver (Ag@PTA).

[0045] The nano-silver with a core-shell structure prepared in this example has regular sh...

Embodiment 3

[0047] A method for preparing a core-shell structure nano-silver antibacterial material based on plant polyphenols, using the following steps:

[0048] 1) The AgNO 3 Dissolve in phosphate buffer at pH=10, then dissolve tannic acid in ultrapure water;

[0049] 2) Add the tannic acid solution obtained in step 1) dropwise to the AgNO obtained in step 1) 3 solution, at room temperature, vibrate with a mechanical oscillator for 25 minutes, centrifuge the reaction solution, collect the precipitate and dissolve it in ultrapure water to obtain the product, wherein the tannic acid and AgNO 3 The mass ratio of is 1:100, and the concentration of the phosphate buffer is 20mM.

[0050] 3) Centrifuge and precipitate the reaction solution after mechanical vibration in step 2), collect the precipitate and dissolve it in ultrapure water to obtain the product core-shell structure nano-silver (Ag@PTA).

[0051] The nano-silver with a core-shell structure prepared in this example has regular s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com